Got an unusual requirement? If you have a liquid that you would like to pack into a bottle, jar, pouch or other container, SFXB is always happy to discuss your application and to offer advice based on our many years’ experience. Even in the rare event that it is not something we can offer a solution for, we can usually point you in the right direction.

Custom Packaging Line: 7 Steps to Unlocking Your Ultimate Production Potential

Your product is unique. Your brand is distinctive. Your growth ambitions are anything but standard. So why are you relying on a standard production line that forces you to compromise?

For many growing businesses in the food and beverage, pharmaceutical, and chemical industries, off-the-shelf machinery seems like a pragmatic choice. It’s available, it has a clear price tag, and it appears to do the job. However, beneath the surface of this “good enough” solution lie hidden costs that silently erode your profitability and stifle your potential.

Consider the daily realities of running a standard line not perfectly suited to your needs:

- Persistent Bottlenecks: Standard fillers struggle with your product’s specific viscosity or foaming characteristics, or your uniquely shaped containers cause frequent jams on the conveyor, slowing down the entire operation.

- Compromised Quality: Inconsistent fill levels, scuffed packaging from ill-fitting guides, or misaligned labels reach the market, subtly damaging the premium brand image you’ve worked so hard to build.

- Excessive Waste: Every bit of product spillage from an imprecise nozzle or every container damaged by an unforgiving capper is a direct hit to your bottom line.

- Labor Inefficiency: Your team is forced to implement manual workarounds, constantly supervising the machine, clearing jams, or performing manual quality checks—tasks that drive up labor costs and introduce the risk of human error.

- Inability to Scale: When a new market opportunity arises—a new product variation, a different package size—your rigid production line cannot adapt, effectively capping your innovation and growth.

The decision to choose standard equipment is often based on a simple, first-order calculation: a lower upfront investment. But the true, long-term calculation—the Total Cost of Ownership—tells a different story. Over time, the accumulated costs of waste, inefficiency, excess labor, and missed market opportunities often far exceed the initial savings. The “cheaper” machine becomes the more expensive liability, a hidden anchor holding your business back.

This is where a paradigm shift is necessary. It’s time to move beyond simply buying machinery and start investing in a production solution engineered specifically for your success.

Non-standard customized automatic filling production line solution| SFXB® Global Industrial Packaging Specialist

Why Choose Xueba’s Tailor-Made Solutions?As a modular packaging system architect, we resolve pain points that off-the-shelf machines cannot address:

- Irregular container handling

- High-viscosity/abrasive media challenges

- Cleanroom-grade production

- Multi-process integration

- Smart IoT-enabled controls

- Future-ready line expansion

Beyond a Vendor, A Partner: The SFXB(Xueba) Collaborative Engineering Philosophy

At SFXB(Xueba), we operate on a fundamentally different principle: we don’t just sell machines; we engineer competitive advantages. With over 20 years of dedicated experience in the packaging automation industry, we have built a reputation not as mere equipment suppliers, but as strategic engineering partners to a diverse portfolio of global clients.

Our entire methodology is built on a foundation of collaborative engineering. This means we work as an extension of your team—your production managers, your engineers, your quality experts—to deeply understand your goals, challenges, and vision. We don’t start with a product catalog; we start with a conversation. This approach is validated by our adherence to the highest international standards, including full CE certification for our equipment, ensuring safety, quality, and reliability.

Choosing a custom solution from SFXB(Xueba) is not a transaction; it’s the beginning of a partnership. It’s a decision to elevate your production from a cost center to a strategic asset that drives growth, quality, and long-term value.

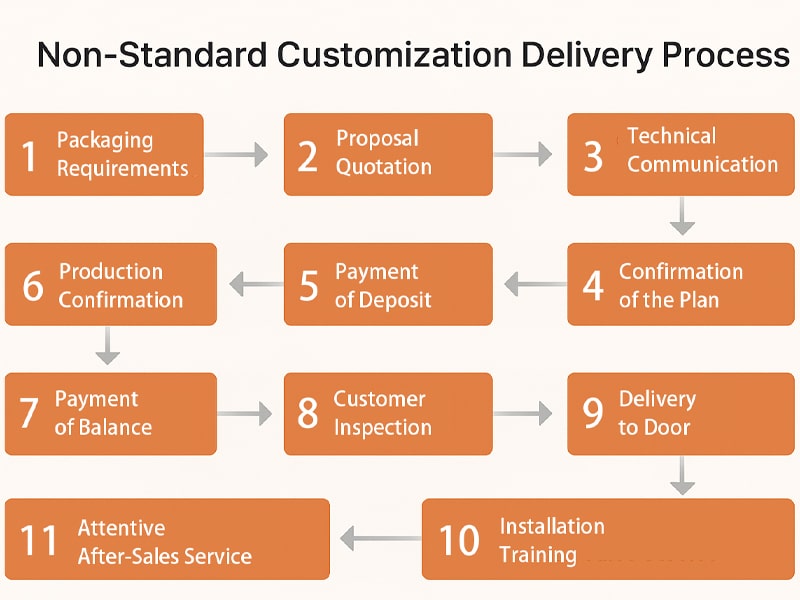

The 7-Step Blueprint: Your Journey from Concept to Commissioning

To demystify the process of creating a bespoke automation solution, we have developed a transparent, structured, and collaborative 7-step blueprint. This proven methodology ensures that every project is meticulously planned, expertly executed, and perfectly aligned with your objectives from the initial idea to the final commissioning and beyond.

|

| Non-standard Customization Delivery Process |

| Step No. | Phase Name | Key Activities | Your Core Benefit |

| 1 | In-Depth Consultation | Product analysis, container specs, goal setting, facility review, budget alignment. | Eliminates guesswork and ensures the solution is right the first time, preventing costly errors. |

| 2 | Custom Proposal & 3D Conceptualization | 2D/3D layout design, equipment specifications, detailed quotation, project timeline. | De-risks your investment by providing absolute clarity and a virtual preview of your line before manufacturing. |

| 3 | Collaborative Design Review | Joint review with your technical team, feedback integration, design finalization. | Ensures the design is not just technically sound but also perfectly optimized for your operators and facility. |

| 4 | Precision Manufacturing | High-grade material sourcing, CNC machining, integration of world-class components. | Guarantees a durable, reliable, and high-performance line built for consistent, long-term operation. |

| 5 | Factory Acceptance Test (FAT) | Full line assembly and testing in our facility using your actual products and containers. | Provides ultimate proof of performance and resolves any issues before shipping, ensuring a smooth start-up. |

| 6 | On-Site Integration | Professional installation, commissioning for peak performance, comprehensive staff training. | Empowers your team with the confidence and skills to operate and maintain the line efficiently from day one. |

| 7 | Lifetime Partnership | Ongoing technical support, spare parts supply, continuous improvement consultation. | Protects your investment for the long term with a dedicated partner committed to your ongoing success. |

Step 1: The Foundation – In-Depth Consultation & Needs Analysis

Our journey together begins not with a sales pitch, but with a deep, diagnostic conversation. This foundational step is the most critical in the entire process. Our senior engineers will meet with your team to conduct a comprehensive needs analysis that goes far beyond basic specifications. We explore:

- Product Deep Dive: We move beyond simple viscosity. We analyze your product’s thixotropy (how its viscosity changes under stress), temperature sensitivity, foaming characteristics, and whether it contains particulates or is chemically aggressive.

- Container Specifications: We examine not just the size and shape of your bottles, jars, or pouches, but also their material rigidity, neck finish tolerances, and the surface properties of your labeling area.

- Operational Goals: We define success together. What is your target CPM/BPM (Containers/Bottles Per Minute)? What are your Overall Equipment Effectiveness (OEE) goals? How critical are rapid changeover times for your product mix? What are your production forecasts for the next 3-5 years?

- Facility & Integration: We analyze your factory layout, identifying any space or height constraints. We confirm the availability of utilities (compressed air, power) and map out the precise integration points with your existing upstream (e.g., bottle unscramblers) and downstream (e.g., case packers) equipment.

- Budget & ROI: We discuss your budget not as a rigid limitation, but as a key parameter for designing a solution that delivers the highest possible return on investment.

This isn’t a sales call; it’s a strategic planning session. By investing this time upfront, we eliminate guesswork and prevent costly misalignments, ensuring the final solution is engineered correctly from the very start.

Step 2: The Vision – Custom Proposal & 3D Conceptualization

With the data gathered from our consultation, our technical team translates your needs into a tangible, visual plan. You won’t have to imagine your future production line; you will see it. Using advanced 3D modeling software, we create a detailed virtual model of the proposed solution. You can virtually walk through the line, view it from any angle, and understand the complete operational workflow before a single piece of metal is cut.

This visual model is part of a comprehensive proposal that includes:

- Detailed 2D and 3D layout drawings.

- A complete equipment list with technical specifications for every component.

- A transparent and detailed quotation.

- A clear project timeline with key milestones.

- A preliminary ROI projection based on your stated goals.

Our 3D conceptualization process completely de-risks your investment. It provides absolute clarity and builds confidence, ensuring that what we propose is exactly what you need and that it will fit perfectly within your facility.

Step 3: The Refinement – Collaborative Design Review & Technical Sign-Off

We believe your expertise in your own operations is invaluable. This is why the design review is not a simple approval step, but a crucial collaborative workshop. We present the detailed proposal and 3D model to your entire team—from lead engineers to the operators and maintenance staff who will interact with the line every day.

This is the stage where we fine-tune the design for real-world usability. Perhaps your maintenance team identifies a way to improve access to a specific motor for easier servicing. Maybe your operators suggest a more ergonomic placement for the Human-Machine Interface (HMI) screen. This feedback is vital. We incorporate your team’s insights to perfect the design.

Once all parties are fully satisfied, we formalize the plan in a final Technical Agreement. This document becomes the definitive, “frozen” blueprint for the manufacturing phase, ensuring perfect alignment and shared ownership of the final solution.

Step 4: The Creation – Precision Manufacturing & Component Sourcing

With the blueprint finalized, our manufacturing team begins the creation process. This phase is a testament to our commitment to quality. A production line is only as strong as its weakest component, which is why we leave nothing to chance.

- Premium Materials: We utilize high-grade stainless steel (SUS 304 for general applications, SUS 316L for corrosive or pharmaceutical-grade products) for all product contact parts, sourced exclusively from certified suppliers.

- Advanced Manufacturing: Our workshops employ modern manufacturing technologies, including CNC machining for critical parts, precision laser cutting, and expert TIG welding to ensure superior build quality, structural integrity, and durability.

- World-Class Components: We integrate components from globally recognized, best-in-class brands (such as Siemens PLCs, Schneider servo drives, and Festo pneumatics). This not only guarantees exceptional reliability and performance but also ensures that spare parts are readily available worldwide, simplifying long-term maintenance for your team.

- Strict Quality Control: A rigorous quality control protocol is enforced at every stage of production, from raw material inspection and in-process checks to sub-assembly testing.

Our meticulous approach to manufacturing ensures your line is built not just to perform, but to endure, delivering consistent, reliable output day after day, year after year.

Step 5: The Verification – Rigorous Assembly & Factory Acceptance Test (FAT)

This is perhaps the most important trust-building event in our entire process. Before your new line ever leaves our facility, we conduct a comprehensive Factory Acceptance Test (FAT). We fully assemble the entire production line in our workshop and run it under real-world conditions.

Critically, we insist on performing the FAT using your actual products and containers, which you provide to us. This is the only way to truly verify performance. We test everything:

- Achieving the target production speed (CPM/BPM).

- Verifying fill accuracy and capping torque.

- Testing the efficiency of changeover procedures.

- Confirming all safety functions and interlocks are operating correctly.

We strongly encourage you and your team to attend the FAT, either in person at our facility or via a live, multi-camera video stream. This act of total transparency provides the ultimate verification. It’s the physical proof that our promised solution works exactly as designed. Any potential issues are identified and resolved in our factory, not yours, completely de-risking the installation phase and guaranteeing a smooth start-up.

Step 6: The Integration – On-Site Installation, Commissioning & Training

Once the FAT is successfully completed, we professionally package and ship the equipment to your facility. But our job is far from over. Our expert engineers arrive on-site to manage the entire installation and commissioning process.

Our engineers don’t just install the hardware; they integrate the solution. This involves:

- Physical Installation: Precisely positioning and assembling the line according to the finalized layout.

- Commissioning: Meticulously fine-tuning every parameter of the line within your actual production environment to achieve and sustain peak performance. This includes optimizing timings, pressures, and sensor sensitivities to create a perfectly synchronized, efficient workflow.

- Comprehensive Training: We provide extensive, hands-on training for both your operators and maintenance personnel. This goes far beyond “how to press the start button.” We cover detailed operation, efficient changeover procedures, routine preventative maintenance, and basic troubleshooting, empowering your team to be fully self-sufficient.

Our goal is a seamless handover. We stay on-site until your line is running smoothly and your team is fully confident and capable of taking ownership, maximizing your uptime and independence from day one.

Step 7: The Partnership – Lifetime Support & Continuous Improvement

For us, the commissioning of your line is not the end of the project; it’s the beginning of a long-term partnership. We stand behind our work for the entire lifecycle of the equipment. Our commitment to your success includes:

- Responsive Technical Support: Access to our expert support team via a 24/7 hotline, email, and remote diagnostic tools that allow us to troubleshoot many issues without an on-site visit.

- Rapid Support Deployment: In the event an issue requires hands-on attention, we can dispatch our field engineers to your site quickly.

- Reliable Spare Parts: We maintain a ready supply of all critical spare parts to minimize any potential downtime.

- Continuous Improvement: Business never stands still. As your needs evolve—new products, different packaging, higher speed requirements—we remain your dedicated automation partner. We are here to consult on how to adapt, upgrade, and continuously improve your line to meet future challenges and opportunities.

Your investment is protected for the long term. We are not just a vendor you bought from; we are the partner you grow with.

The Tangible ROI: Quantifying the Impact of a SFXB(Xueba) Custom Solution

An investment in a custom automation line is a strategic business decision, and its success should be measured in clear, quantifiable returns. While the initial investment for a custom solution may be higher than an off-the-shelf machine, the ROI delivered through superior performance often results in a lower Total Cost of Ownership and a significantly faster payback period. Here’s how our clients see the impact:

- Increased OEE (Overall Equipment Effectiveness): By engineering a line that perfectly handles your specific product and container, we eliminate the micro-stoppages, jams, and reduced speed that plague standard systems. Clients moving from compromised standard lines to a SFXB(Xueba) custom solution often report OEE improvements of 15-25%.

- Reduced Labor Costs: A fully integrated and reliable automated line eliminates the need for manual workarounds and constant supervision. This can reallocate 1-3 full-time employees per shift from low-value monitoring to more value-added tasks, delivering direct and substantial payroll savings.

- Minimized Product & Material Waste: Precision filling that hits target weight every time, gentle container handling that prevents damage, and accurate capping that eliminates leaks can drastically cut waste. It’s common for our solutions to reduce product waste from a typical 2-3% down to less than 0.5%, saving thousands of dollars in raw materials and finished goods annually.

- Enhanced Market Agility: This is the strategic game-changer. A custom line can be designed for rapid, tool-less changeovers (e.g., under 30 minutes between different products or bottle sizes). This agility means you can say “yes” to new opportunities, launch new SKUs, and respond to changing market demands weeks or even months faster than competitors tied to rigid, standard equipment. This capability transforms your production line from an operational tool into a strategic weapon.

From Our Workshop to Your Factory Floor: A Case Study in Customization

To illustrate the power of our process, consider the challenge faced by a fast-growing craft sauce company.

The Problem: The company was producing a high-viscosity, chunky salsa that they filled into a uniquely shaped, wide-mouth glass jar. Their semi-manual filling process was painfully slow, highly inconsistent (leading to significant product giveaway), and created a massive production bottleneck. This prevented them from accepting a lucrative contract from a major national retail chain.

The Solution: They partnered with SFXB(Xueba). Following our 7-step blueprint, we began with an in-depth consultation (Step 1) to analyze the salsa’s properties and the jar’s specific geometry. Our engineers then designed a custom solution (Step 2) featuring a servo-driven piston filler with a specialized, wide-aperture, non-drip nozzle to handle the chunky particulates without crushing them. This was integrated with a custom chuck capper engineered for their non-standard lid. The 3D model allowed the client’s team to visualize the workflow and suggest an improved conveyor layout for better operator access (Step 3). The line was then built with 316L stainless steel contact parts and passed a rigorous FAT (Step 5) using 50 gallons of the client’s actual salsa and several cases of their jars.

The Results: Within three months of our on-site installation and training (Step 6), the client achieved transformative results. They increased their production speed by 400%, reduced product giveaway due to overfilling by 90%, and eliminated packaging waste from spillage. Most importantly, they confidently accepted and fulfilled the new retail contract, leading to a 60% increase in annual revenue. The entire project achieved a full return on investment in just 11 months.

Your Questions, Answered: Custom Automation FAQ

Q1: How long does a custom project typically take?

A project's timeline can vary based on complexity, but a typical project ranges from 2 to 10 weeks from the final contract signing to shipping from our facility. We provide a detailed, transparent project timeline with key milestones as part of our proposal in Step 2.

Q2: Is a custom line significantly more expensive than a standard one?

While the initial investment for a custom line is often higher, the long-term value is far greater. When you factor in the ROI from increased efficiency, dramatically reduced waste, lower labor costs, and the strategic ability to capture new markets, the Total Cost of Ownership for a custom line is frequently lower than a standard machine that requires constant workarounds and limits your growth.

Q3: What industries do you specialize in?

We have extensive experience providing custom automation solutions for a wide range of industries, with core specializations in Food & Beverage (sauces, drinks, oils), Pharmaceutical (syrups, reagents), and Daily Chemicals (lotions, detergents, cosmetics).

Q4: What happens if my product or packaging changes in the future?

We design with the future in mind. During our initial consultation, we specifically discuss your future plans and growth ambitions. We can build in flexibility from the start, and many of our lines are designed to be easily adapted with new change parts or minor modifications to accommodate future product or packaging variations.

Q5: Can you integrate your line with my existing equipment?

Absolutely. Seamless integration is a core competency and a key part of our process. We ensure a perfect digital and physical "handshake" between our line and your existing upstream and downstream equipment, creating a single, unified, and efficient production workflow.

Q6: What kind of warranty and support do you offer?

Every SFXB line comes with a comprehensive warranty (typically 1-2 years), but our commitment is to a lifetime partnership. This includes ongoing technical support, remote diagnostics, and a reliable supply of spare parts to ensure your line continues to operate at peak performance for years to come.

Take the First Step Towards Your Unparalleled Production Efficiency

Stop forcing your unique products into standard boxes. Stop accepting the hidden costs of compromise and inefficiency. It’s time for a production solution that is as ambitious and unique as your brand.

It’s time for a partnership with SFXB(Xueba)—a partnership that delivers a lasting competitive edge through superior efficiency, uncompromising quality, and strategic agility.

Schedule Your Free, No-Obligation Consultation Today.

Click the button below to speak with one of our automation experts and begin your journey from concept to competitive edge. Let’s build your future, together.

Start Your Smart Packaging Journey

📞 Global Hotline: +86 18028686502

📧 Technical Consultation: xuebapack@gmail.com

🌍 Local Support: English | Deutsch | Español | Français

Comments