Products Description

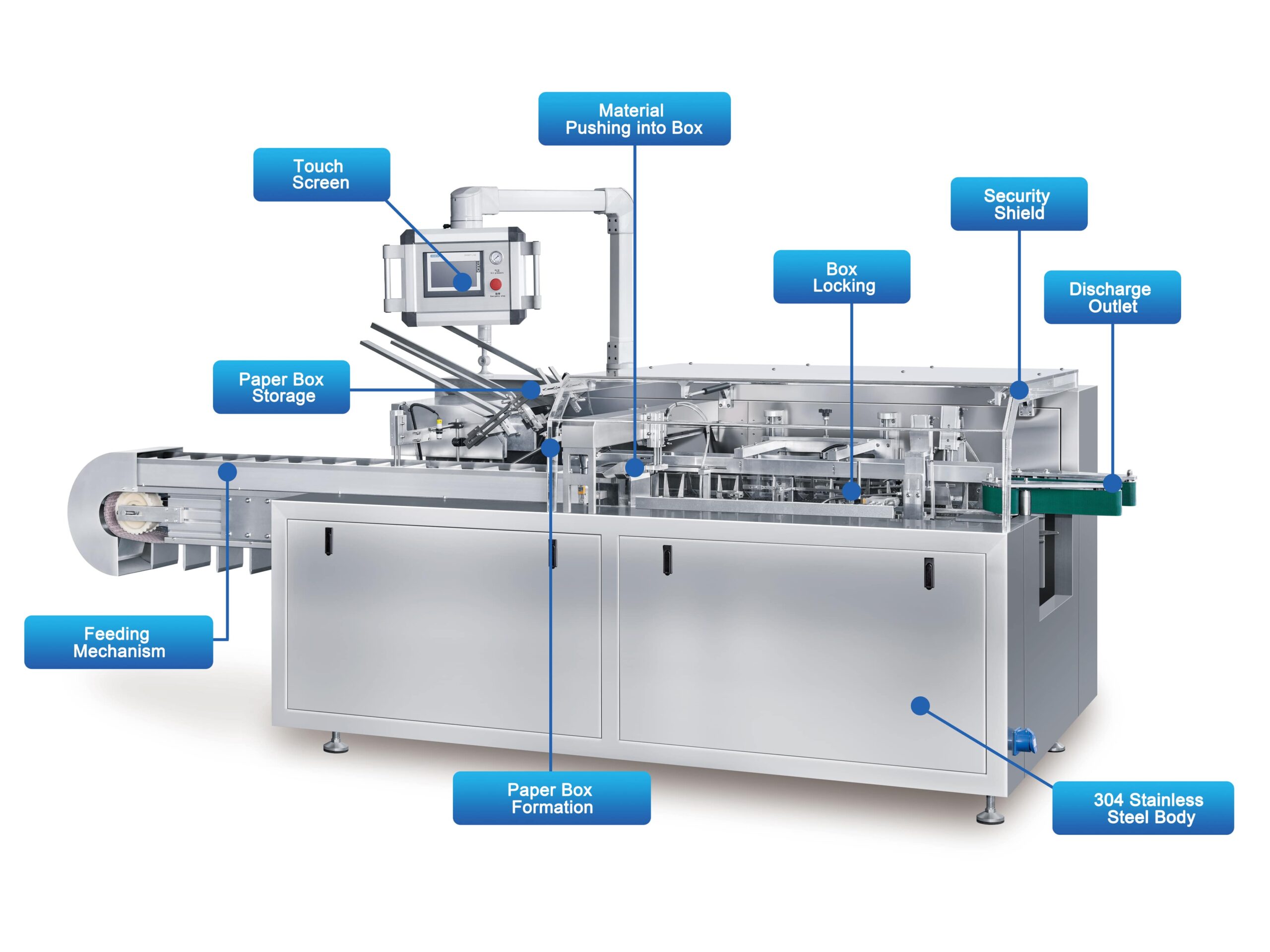

The GDZ-130 Automatic Cartoning Machine is a new type of machine developed and designed by integrating advanced domestic and international technologies for the automatic feeding and boxing of multiple varieties and specifications of products. The overall design is highly efficient and compact, and the feeding mechanism is easy to adjust. The desired number of boxes to be filled can be set on the operation screen. Through various automatic feeders, it achieves the entire process of automatic online material conveying and detection, folding of instructions (1 to 4 times folding and conveying), material insertion into the box, batch number printing, sealing of paper tongues at both ends of the paper box (also suitable for hot melt adhesive), rejection of missing materials, and final product output, among other functions.

|

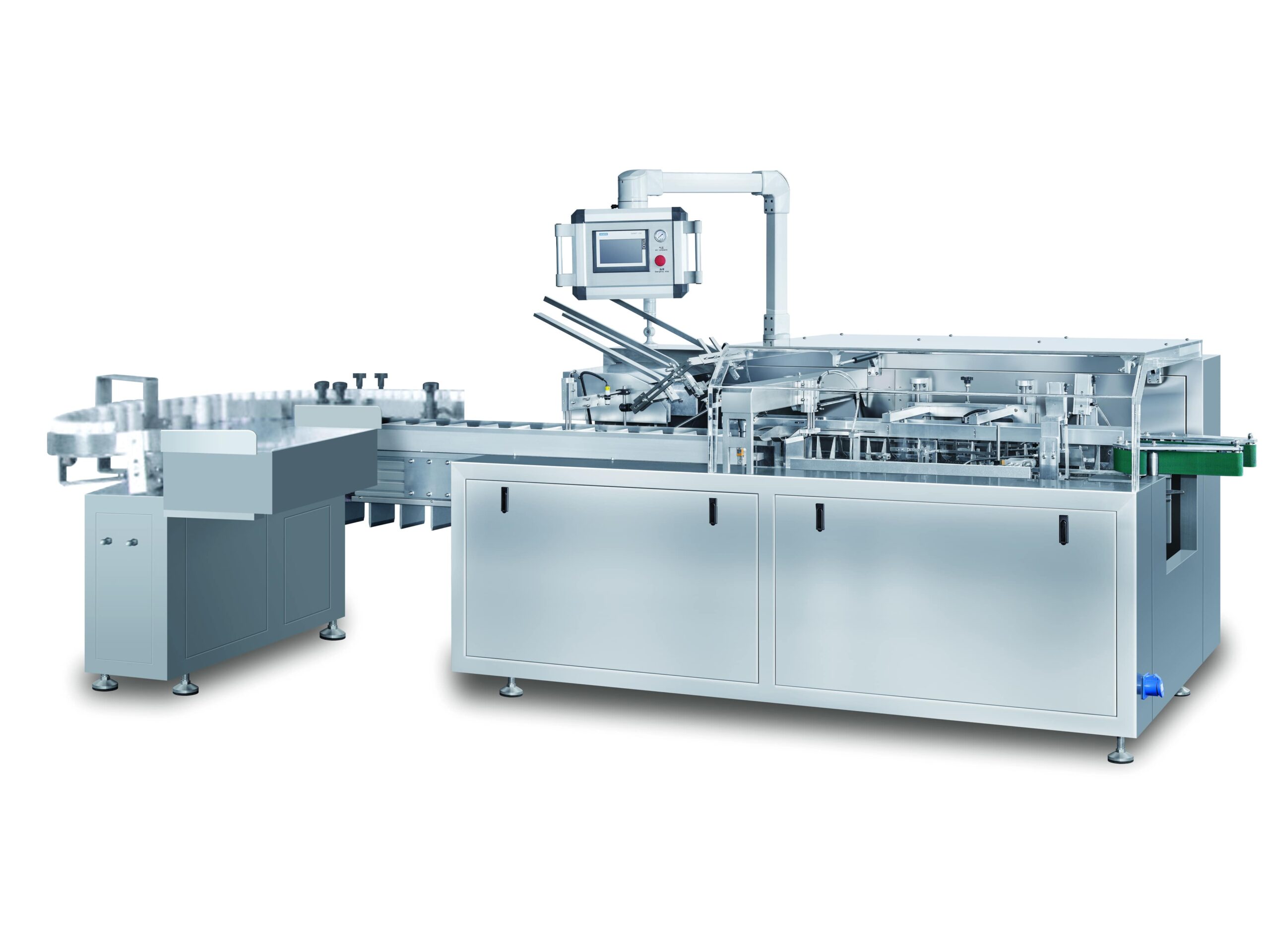

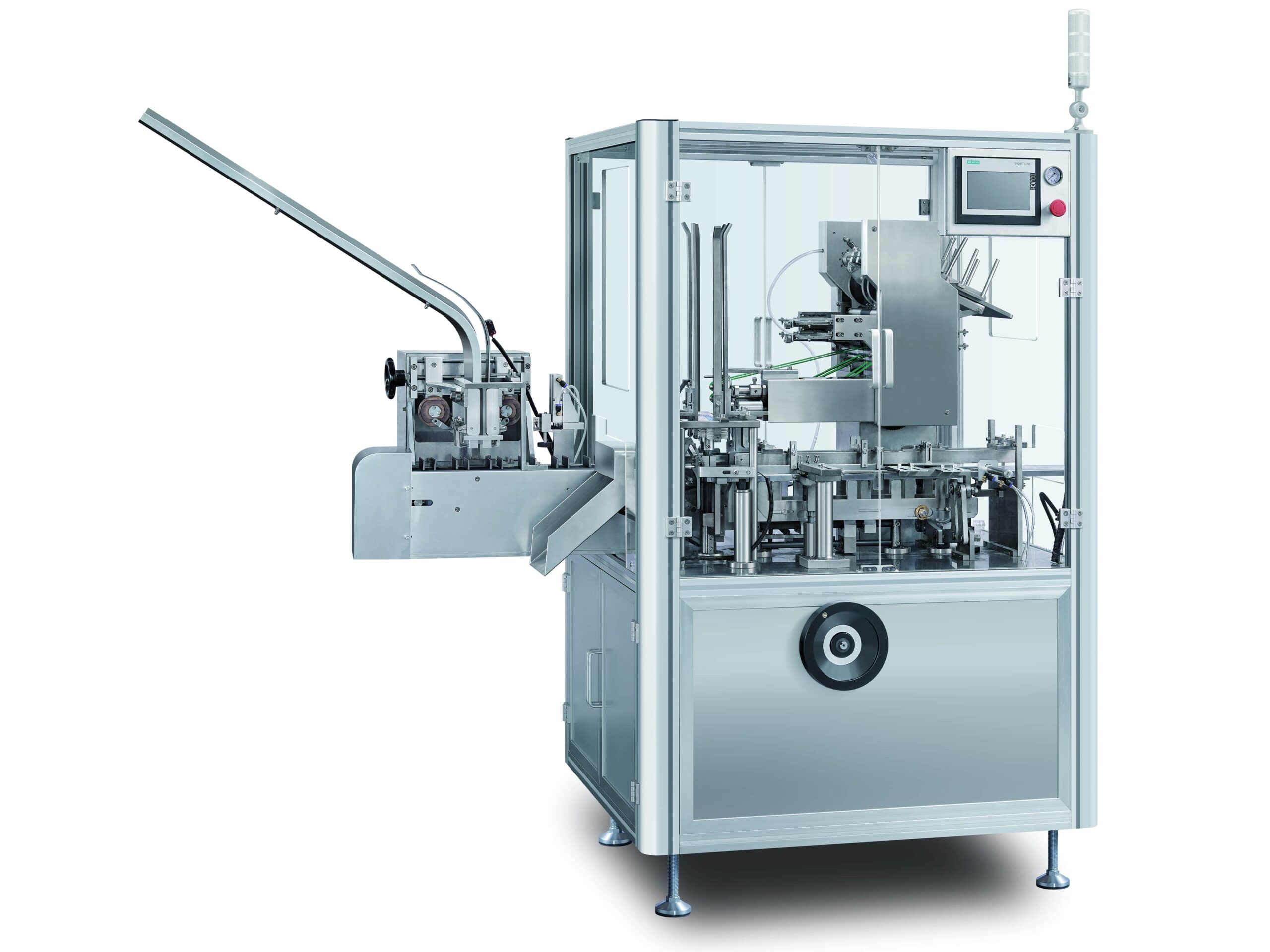

| Bottle Labeling Machine + Box Packaging Machine (GDZ-130P) |

|

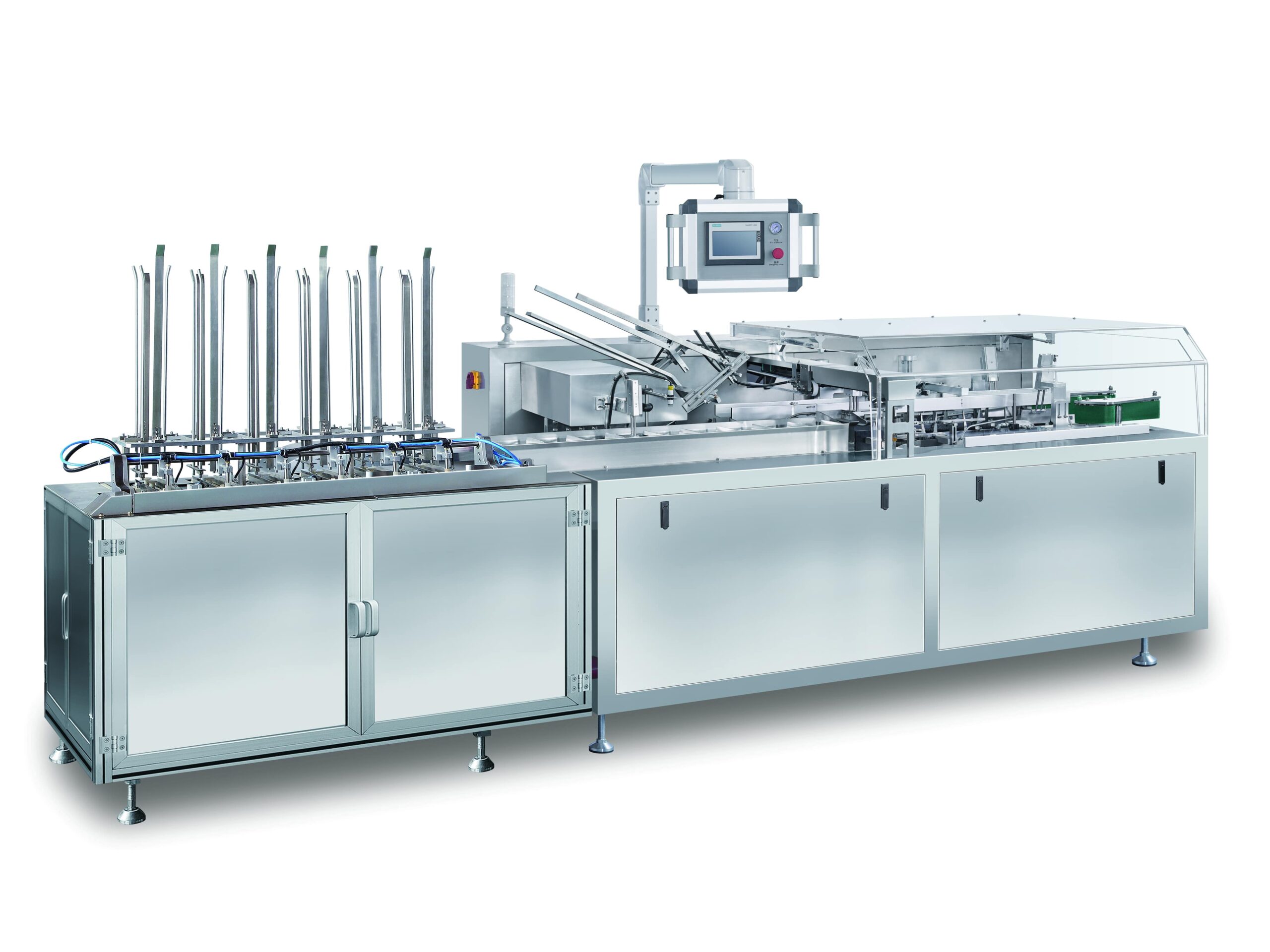

| Multi-Material Packaging Feeder + Cartoning Machine(GDZ-130D) |

|

| Multi-Material Packaging Feeder + Cartoning Machine (GDZ-120E) |

|

|

|

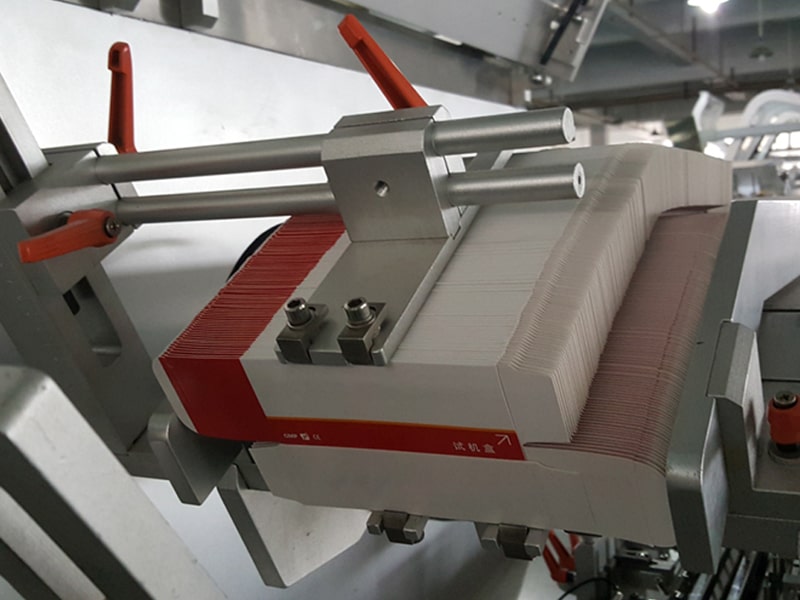

| Paper box storage

It can accommodate more finished paper boxes at once, reducing manual intervention. It seamlessly integrates with the automatic box suction device, which can significantly enhance work efficiency and machine automation. |

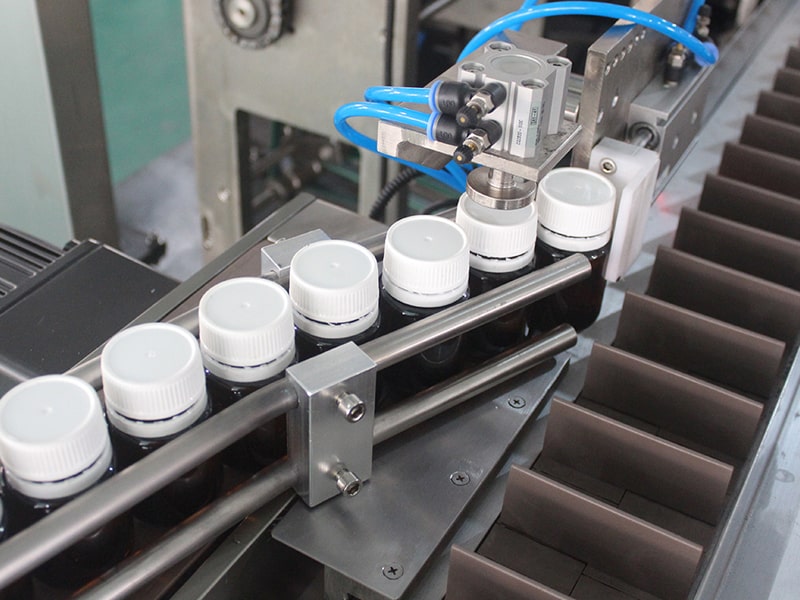

Material conveying mechanism

Different conveying mechanisms are configured based on the material to achieve machine automation operation. |

|

|

|

|

| Instruction manual folding mechanism It can achieve multiple folding modes (1-4 folds) and is synchronized with the material’s insertion into the box through photoelectric control. |

Hot melt adhesive machine (Optional depending on the paper box) |

Box sealing mechanism It can achieve tongue insertion and hot melt adhesive box sealing. |

Technical parameter

- Adaptability to different sizes, shapes, and types of boxes, as well as various types of items (with different feeding mechanisms) to meet diverse requirements.

- PLC automatic control system, variable frequency speed regulation, and electrical components are sourced from internationally renowned brands.

- Utilizes a human-machine interface (HMI) operating system, with automatic shutdown in case of mechanical overload.

- Automatic rejection of boxes lacking packaging materials and instructions.

- Equipped with self-diagnostic capabilities, capable of monitoring equipment status and issuing alerts for timely maintenance and repair, as well as product counting functions.

- The machine features a simple overall structure, occupies a small footprint, maintains stable performance, and is easy to operate and understand.

Main Technical Parameters

| Cartoning speed 30-120 cartons/min | |||

| Carton | Quality | 250-350g/㎡【depending on carton size】 | |

| Size (L×W×H) | (70-200)mm×(35-120)mm×(14-70)mm | ||

| Leaflet | Quality | 60-70g/㎡ | |

| Unfolded leaflet size(L×W) | (80-250)㎜×(90-170)㎜ | ||

| Fold(L×W) | 【1-4】Folds | ||

| Compressed air | Working pressure | ≥0.6mpa | |

| Air consumption | 120-160L/min | ||

| Power supply | 380V 50HZ | ||

| Main motor power | 1.5kw | ||

| Overall dimensions(L×W×H) | GSZ-130 | 2650㎜×1300㎜×1900㎜ | |

| GSZ-130D | 4300㎜×1300㎜×1900㎜ | ||

| GSZ-130E | 5500㎜×1300㎜×1900㎜ | ||

| GSZ-130P | 4300㎜×1300㎜×1900㎜ | ||

| Machine weight | GSZ-130 | About 1400kg | |

| GSZ-130D | About 1600kg | ||

| GSZ-130E | About 1800kg | ||

| GSZ-130P | About 1600kg | ||

COMPONENT LIST

| No. | Name | Model/Spec. | Brands | Qty |

| 1 | PLC | S7-200 ST40 | SIEMENS | 1 |

| 2 | Touch screen | Smart700 1 | SIEMENS | 1 |

| 3 | Frequency converter | DVP01521A | SIEMENS | 1 |

| 3 | AC contactor | GML-12 | LG | 1 |

| 4 | E-stop | ZB2 BC4D | SCHNEIDER | 1 |

| 5 | Intermediate relay | LY2M 24V | OMRON | 5 |

| 6 | Encoder | E6B2-CWZ6C 1000P/R | OMRON | 1 |

| 7 | Approaching switch | TL-Q5MC1-Z | OMRON | 1 |

| 8 | Photoelectric sensor | E3ZG-D61-S | OMRON | 1 |

| 9 | Optical fiber amplifier | E3X-NA11 | OMRON | 1 |

| 10 | Optical fiber unit | E32-ZD200 | OMRON | 1 |

| 11 | Gear motor | CH-32-1500-10-S | VOLSON | 1 |

| 12 | Indexing box | DS83-4L-180 | ZHONGLI | 1 |

| 13 | Air source handling unit | GFR30010-F1 PT | AIRTAC | 1 |

| 14 | Solenoid valve | 4V210-08-B | AIRTAC | 2 |

| 15 | Vacuum solenoid valve | 3V310-10-B-W | AIRTAC | 1 |

| 16 | Vacuum generator | ZH20DS-03-04-04 | AIRTAC | 1 |

| 17 | Foam silencer | PAL04 | AIRTAC | 2 |

| 18 | Cylinder | TN25*30 | AIRTAC | 1 |

| 19 | Cover | Stainless steel | 1 SET |

PACKING LIST

| No. | Name | Spec. | Unit | Qty | Note |

| 1 | Automatic cartoning machine | GSZ-130P | set | 1 | |

| 2 | Straight screwdriver | 4″ | pc | 1 | |

| 3 | Cross screwdriver | 4″ | pc | 1 | |

| 4 | Monkey wrench | 8″ | pc | 1 | |

| 5 | Monkey wrench | 10″ | pc | 1 | |

| 6 | Allen wrench | Lengthened | set | 1 | |

| 7 | Pressure oil can | Pressure oil can | pc | 1 | |

| 8 | Solid wrench | 8-10 | pc | 1 | |

| 9 | Solid wrench | 12-14 | pc | 1 | |

| 10 | Solid wrench | 17-19 | pc | 1 | |

| 11 | Vacuum suction cup | Φ32 | pc | 4 | |

| 12 | Leaflet conveyor | 900×15×1 | pc | 2 | |

| 13 | Leaflet conveyor | 840×15×1 | pc | 2 | |

| 14 | Flat nose pliers | 8″ | pc | 1 | |

| 15 | Long nose pliers | 4″ | pc | 1 | |

| 16 | Spring sheet | pc | 4 | ||

| 17 | Steel letters | 0-9 (back view letter) | pc | 10 for each |

Technical documents

| No. | Technical documents | Unit | Qty | Note |

| 1 | User’s manual for GDZ-130 automatic cartoning machine | copy | 1 |

Scope Of Application

- Pharmaceutical Industry: Tablets, capsules, injections, etc.

- Food and Beverage Industry: Food products (such as chocolates, pastries, biscuits) or liquid products (such as beverages, sauces).

- Cosmetics Industry: Cosmetics and personal care products.

- Household Products: Detergents, cleaning agents, soaps, etc.

- Electronics Industry: Electronic devices, components, etc.

- Toy Industry: Toy products.

- Industrial Products: Various industrial products and mechanical components, automotive parts, etc.

- Medical Devices: Medical equipment and medical consumables, and more.

- Office Supplies: Stationery, office supplies, etc .

Comments