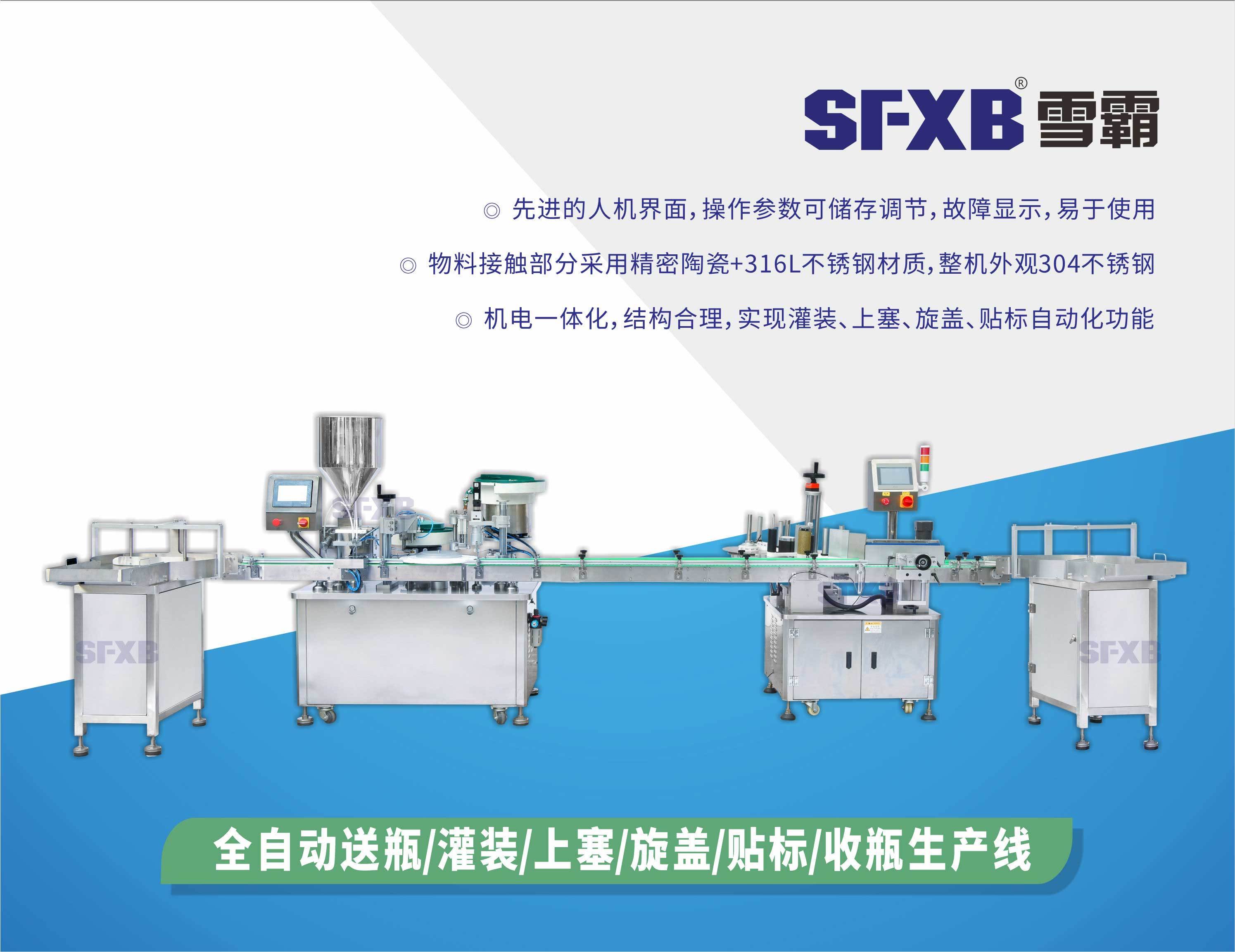

Products Description

■ Adopt Xueba high-precision ceramic pump;

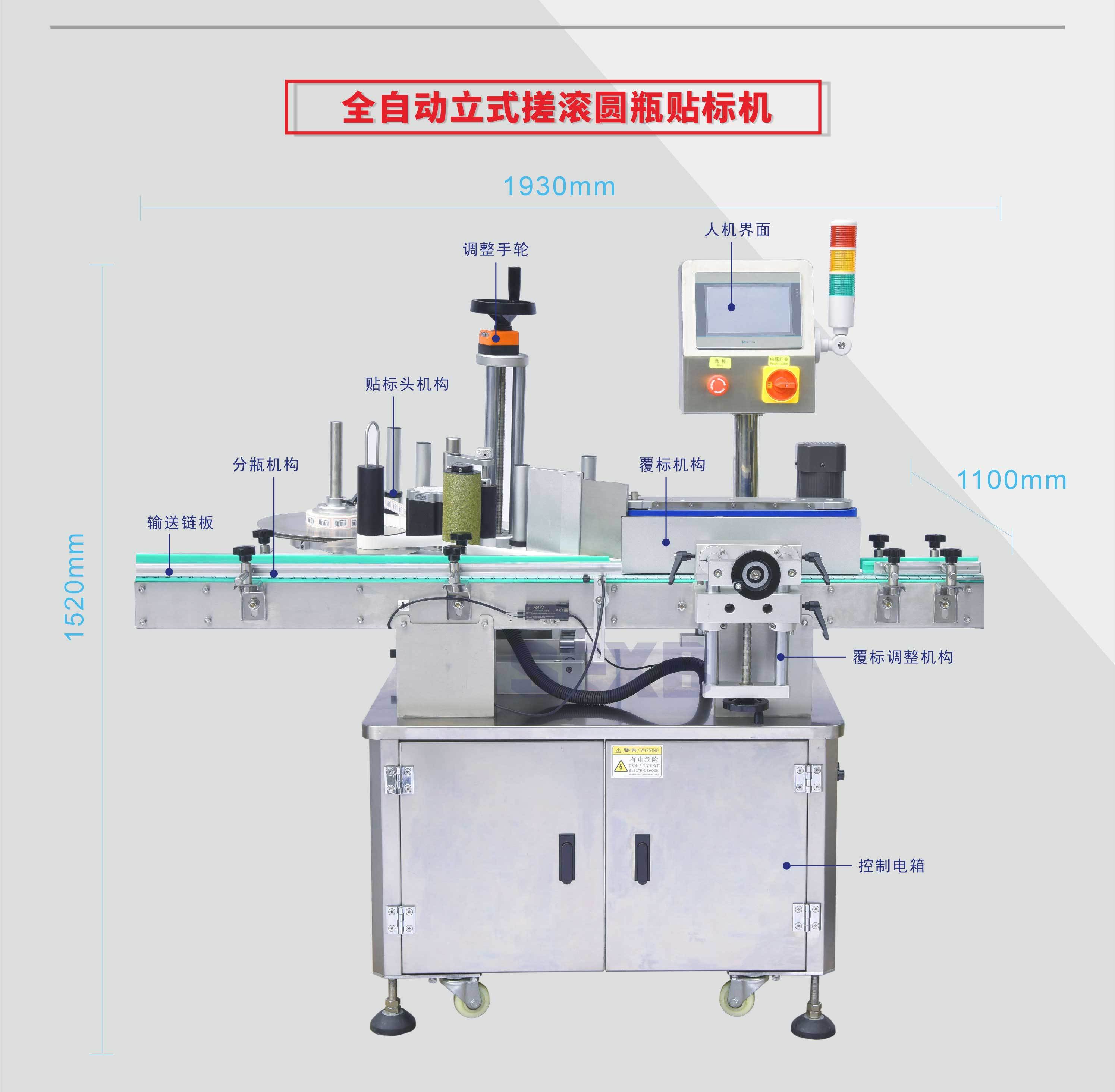

■ Fully automatic bottle feeding, filling, plugging, capping, capping and labeling integration;

■ Suitable for small-dose precise quantitative filling.

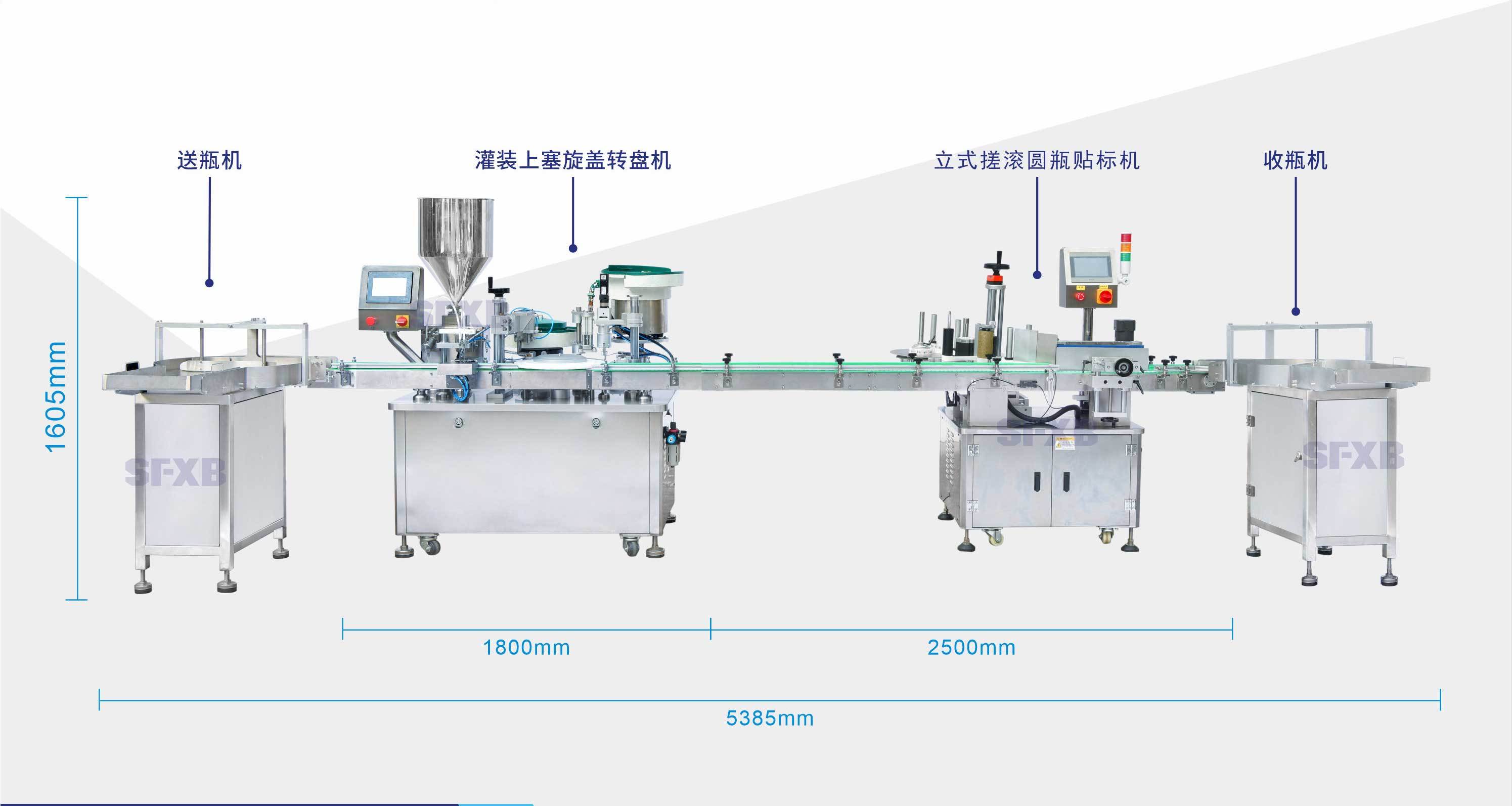

Technical parameter

| pump head | Valveless ceramic pump |

| Filling accuracy | Soil 0.5%

(Using water as the standard, more than 30% of the maximum filling value can achieve accuracy) |

| Filling range | 10 ml (optional ceramic pump with required specifications) |

| Yield | 0~26 bottles/min |

| powered by | AC220V 50/60Hz 1500W |

| air supply | 0.4~0.6Mpa |

| Host size (length L*width W*height H | 5385×1260×958(mm) |

Scope Of Application

■ Important components for quantitative distribution or continuous delivery of materials in experimental equipment, analytical equipment, and pharmaceutical equipment ;

■ Widely used in the precise quantitative filling of pharmaceutical, pharmaceutical, food, chemical, cosmetic and other industries ;

■ Precise and quantitative filling of liquids such as blood, biological reagents, oral agents, injections, high-end cosmetics, essences, e-cigarette oil, and fungicides;

■ Precise quantitative filling of various acid-base corrosive liquids.

Comments