The 23rd CPhI China (World Pharmaceutical Raw Materials China) and 18th PMEC China exhibitions will run June 24–26, 2025 at the Shanghai New International Expo Center (SNIEC). As a premier global platform for ceramic pump filling innovations and pharmaceutical packaging technology, this co‐located event spans 230,000 m² with over 3,500 exhibitors showcasing everything from raw materials to lab equipment and automated filling lines. Under China’s 2023–25 action plan to enhance quality and drive international integration, CPhI & PMEC China 2025 will bring together leading manufacturers, R&D experts, and buyers to explore cutting-edge solutions—especially the latest in contamination-free ceramic pump filling systems that ensure unparalleled precision and hygiene.

SFXB’s Exhibit: Equipment Table

| Machine | Key Features & Capabilities |

| XBXG-20 series Desktop Rotary-type Filling And Capping Machine | Compact all-in-one desktop filler. It automatically feeds bottles, uses a gentle peristaltic pump for filling, and then servo-caps. Ideal for small‐dose liquid dispensing with precise volumetric control. (Great for lab-scale or pilot production lines.) |

| Double-Servo Ceramic Pump Filling, Plugging & Capping Machine | Fully automatic production line: bottle loading→filling→plugging→corking→capping with servo torque capping. Uses Xueba’s high-precision ceramic pump to handle corrosive or high-value liquids. Output ~35–40 bottles/min at ±0.5% accuracy. Suitable for vials or bottles in pharma, cosmetics or chemical labs. |

| XBZXY-2 Matrix High-Precision Rotary-Valve Plunger Ceramic Pump Filler | Matrix 6-channel filler with rotary-valve ceramic plunger pump. Designed for ultra-precision small-dose filling – ideal for skincare and high-end beauty products. Rotary valve design ensures minimal waste and exact dosing, crucial for luxury cosmetics or biotech reagents. |

| XBZP-25 Series Desktop Ceramic Pump Filler & Capping Machine | Desktop filler-capper series (model XBZP-25s). Compact design for small-scale production. Integrates a ceramic piston pump and capping station for bottles and jars. Delivers high-precision filling (±0.5% with water) at ~25–28 bottles/min. Ideal for R&D and niche products like specialty pharmaceuticals or ointments. |

| Desktop Ceramic-Pump Filling Production Line(Bottle Feed / Fill / Cap / Discharge) | Integrated line for hard-to-hold containers. It feeds bottles, fills them via a ceramic plunger pump, then servo/pneumatic caps and unloads. Engineered for bottles that can’t stand easily (e.g. special vials). Fully GMP-compliant (no-bottle→no-fill, auto eject) and uses a valveless ceramic pump for ultra-clean filling. |

| XBWXY-6 Matrix High-Precision Valveless Ceramic Pump Filler | Matrix (6-head) desktop valveless pump filler. Handles multi-well plates (e.g. 96-well) or bottles. Uses plunger-style ceramic pumps (99.99% alumina) for inert, contamination-free filling. Fills 20–900 μL per dispense with ±0.5% accuracy. Yield ~10–30 cycles/min. Ideal for labs and pilot runs in biotech, pharma, cosmetics and food R&D. |

| XBWG Single-Head Valveless Ceramic Plunger Filling Machine | Portable single-channel filler with human-machine interface. Employs a valveless ceramic plunger pump (high-purity alumina) for high-purity, corrosion-resistant dosing. Capable of precise quantitative fills (customizable volume). Stainless-steel frame and advanced controls make it ideal for lab or workshop use in pharma, cosmetics, and specialty chemicals. |

| Matrix High-Precision Valveless Ceramic Pump Filling Machine | High-precision desktop filler with multiple valveless ceramic pumps. It fills tiny doses with virtually no waste, perfect for high-end skincare or biotech samples. Touchscreen interface and 304SS housing enable set-and-forget operation. Filling accuracy ±0.5% (water standard) with 40–100 cycles/min. Used for sensitive fluids (blood reagents, essences, e-liquids, etc.) in labs and fine-chemistry production. |

|

|

|

| XBZP-25 series desktop ceramic pump filling and capping (capping) machine | XBWXY-6 Matrix High Precision Valveless Ceramic Pump Filling Machine | Desktop ceramic pump filling production line (bottle delivery/filling/capping/bottle output) |

SFXB (XueBa) High-Purity Ceramic Pump Performance Characteristics

The SFXB ceramic pump features zero liquid contamination, high precision, and long service life:

1. Meets the highest hygiene and health standards in the pharmaceutical, food, and cosmetics industries.

2. Exhibits extremely inert chemical stability, including acid and alkali resistance, corrosion resistance, and high-temperature resistance.

3. Is superhard and wear-resistant, with minimal particle release and an extended service life.

4. Has a dense material structure with near-zero water absorption, a superior surface finish, and very low friction, resulting in minimal material residue. Its coefficient of thermal expansion is extremely low, piston clearance is optimized, filling accuracy is enhanced, and it supports online cleaning and sterilization.

Ceramic Pump Technology & Advantages

Central to SFXB’s equipment is their proprietary ceramic pump technology. These pumps use 99.99% alumina or zirconia ceramic for the plunger and pump sleeve, giving inert chemical stability and virtually zero contamination. Because ceramic is super-hard and corrosion-resistant, SFXB pumps can handle strong acids/bases and high temperatures. Key performance traits include zero water absorption, minimal friction, and extremely low particle release. In practice this means no pollution of product, the highest pharmaceutical hygiene, and very long service life.

For precision filling, the ceramics’ low thermal expansion and tight piston clearance ensure consistent, accurate dosing. Indeed, SFXB reports filling accuracy better than ±0.5% (using water as reference). The pumps also allow online CIP/SIP cleaning. As one industry source notes, ceramic pump fillers can achieve high purity and long lifetimes: “Liquid non-polluting, high precision…very high surface finish…water absorption as low as zero…low thermal expansion coefficient”. This aligns with SFXB’s emphasis that their high-purity ceramic pumps are inert, wear-resistant plunger pumps designed for ultra-clean filling in pharma, food and cosmetics.

SFXB’s lab-scale and bench-top machines leverage this ceramic pump tech. For example, the XBWXY-6 matrix filler (for 96-well plates) delivers ±0.5% precision with 20–900 µL volumes. The XBWG single-head filler uses a valveless ceramic plunger pump for precise dosing, featuring a user-friendly interface and stainless steel frame. All such units comply with GMP, eliminating “no-bottle no-fill” and “no-cap no-turn” issues. In sum, SFXB’s R&D combines lab-grade ceramic pump modules with industrial automation, offering customers contamination-free, high-precision filling solutions for R&D and small-batch production.

Applications in Pharma, Cosmetics & More

SFXB’s machines are used across pharma, biotech, cosmetics, food/beverage and chemical industries. In pharmaceuticals and biotech, these fillers handle vials, syringes, IVD reagents, and bio-samples. Customers fill blood samples, culture reagents, injections, vaccines, and biological liquids with the ceramic pump machines. For example, they can precisely dose e-liquids and high-end beauty serums with no contamination. Food and beverage plants also use SFXB lines for sauces, condiments and oils – as noted on their homepage, SFXB supplies production lines for condiments, sauces, beverages and health products. In cosmetics, the equipment fills emulsions, creams and essences into bottles and tubes. Even chemical manufacturers leverage the ceramic pumps to meter aggressive or corrosive fluids (acids, alkalis, solvents) because the ceramic material resists corrosion. In short, SFXB’s ceramic-filler machines serve any application needing safe, ultra-precise liquid handling – from food-grade flavors to pharmaceutical injectables and luxury skincare products.

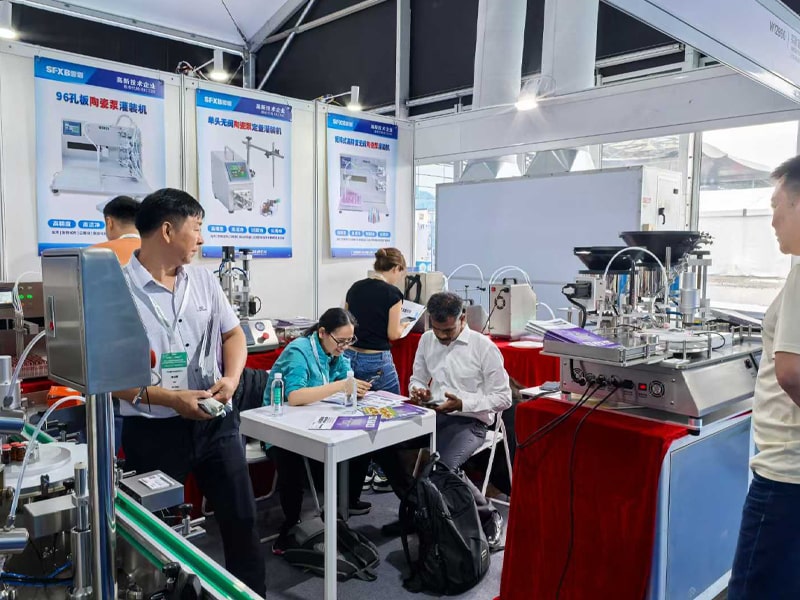

SFXB’s Exhibition Highlights

At CPHI & PMEC China 2025 (Booth W12B60), SFXB will highlight its ceramic pump innovations and complete filling solutions. A standout feature is zero-waste micro-dosing – the matrix valveless filler can fill tiny doses with virtually no leftover, which is critical for costly cosmetics or biotech samples. Another highlight is full automation: the Double-Servo Filler performs bottle loading → plugging → capping seamlessly. The new XBZXY-2 rotary-valve filler promises “minimal waste and accurate dosages” in high-end cosmetics. Across the booth, SFXB showcases how its ceramic pump technology translates into highest hygiene and precision. Demonstrations will emphasize features like automatic servo capping, touch-screen controls, and GMP compliance. Together these form a suite of “cutting-edge” packaging solutions that meet global standards. Visitors will see how SFXB is pushing ceramic pump filling to new heights in accuracy and reliability – underscoring why their brand is trusted worldwide.

Frequently Asked Questions (FAQ)

1.What are the dates and venue for CPhI & PMEC China 2025?

CPhI & PMEC China 2025 runs from June 24 to June 26, 2025, at the Shanghai New International Expo Center (SNIEC).

2.What does SFXB (XueBa) specialize in at the Expo?

SFXB will showcase its full line of high-precision ceramic pump filling and capping equipment, from desktop lab-scale units to fully automated production lines, all featuring contamination-free ceramic pump technology.

3.What is “ceramic pump technology”?

These pumps use 99.99% alumina or zirconia ceramic plungers and sleeves to achieve inert chemical stability, zero water absorption, minimal friction, and virtually zero particle release—ensuring no contamination of liquid products.

4.What key advantages do SFXB’s ceramic pumps offer?

● Ultra-high hygiene: Meets the strictest pharmaceutical, food, and cosmetics standards. ● Chemical resistance: Handles acids, bases, solvents, and high temperatures without degradation. ● Precision & accuracy: Typical filling accuracy better than ±0.5% (water reference). ● Longevity: Super-hard, wear-resistant ceramic with minimal particle release and long service life.

5.How do I choose the right ceramic pump filling machine for lab-scale or small-batch production?

Consider required throughput (bottles per minute or µL per dispense), accuracy (±0.5% or better), and whether integrated capping is needed. For R&D or small-batch work, a benchtop model like the XBZP-25 series offers ±0.5% precision in a compact footprint with built-in capping—ideal for laboratory environments.

6.What filling accuracy and speed can users expect?

Depending on the model, SFXB machines deliver ±0.5% volumetric accuracy, with outputs ranging from ~10 μL doses up to 40 bottles/min, and cycle rates up to 100 cycles/min for micro-dosing applications.

7.Which industries benefit most from these ceramic pump fillers?

Pharmaceuticals and biotech (vials, syringes, IVD reagents), cosmetics and personal care (creams, serums), food and beverage (sauces, oils), and specialty chemicals (corrosive or high-value fluids).

8.What does “no-bottle no-fill” and “no-cap no-turn” compliance mean?

These GMP-compliant interlocks ensure that if no container is detected, the filler won’t dispense, and if no cap is present, the capping station won’t engage—preventing waste and ensuring safety.

9.How is online cleaning and sterilization handled?

SFXB’s ceramic pumps support both CIP (Clean-In-Place) and SIP (Steam-In-Place) protocols, allowing automated, thorough cleaning and sterilization of internal fluid paths without disassembly.

10.What ensures long-term filling accuracy and stability in ceramic pump systems?

● Low thermal expansion: piston clearances remain consistent despite temperature changes ● Super-hard, wear-resistant ceramic: prevents particle release over time ● Optimized piston–sleeve gap: engineered for ±0.5% volumetric precision ● Routine CIP/SIP and calibration: online monitoring plus periodic maintenance keeps performance stable over the life of the equipment.

Comments