What Is a Weighing Filling Machine?A Weighing Filling Machine (also called a net weight filler or weigh filler) is an automated packaging device that dispenses product into containers by weight. In other words, it weighs each container as it is being filled, stopping the flow when the target net weight is reached. This ensures every package has the exact amount of product specified on the label. Such precise filling is crucial in industries like food & beverage, pharmaceuticals, and chemicals, where overfilling wastes material and underfilling violates regulations. By integrating a scale or load cell with the filling mechanism, weigh fillers improve consistency, reduce giveaway, and build trust in product quality. (These machines are sometimes called weighmetric filling machines, weight filling machines, weigher packing machines, or weighing packaging machines in different markets.)

How Weighing Filling Machines Work

A weighing filling machine combines a bulk product hopper or reservoir with a precise weighing system and a discharge nozzle or valve. In operation, an empty container is placed on a built-in scale (often part of the conveyor or platen). The machine then dispenses product – via gravity, pump, or feeder – into the container while continuously monitoring the weight. As soon as the scale reads the preset target weight, the filling stops. This “fill-to-weight” process typically uses a two-stage approach: a fast, coarse fill to approach the target quickly, followed by a slower, fine feed to hit the exact weight. The steps usually include:

1. Container loading: An empty container is placed on the integrated scale and tared (the empty weight is zeroed out).

2. Product dispensing: Product flows from the hopper into the container. Early in the cycle a rapid fill is used to approach the desired weight.

3. Precision fill: As the scale nears the target weight, the machine slows the flow for fine control. The weighing sensor continuously tracks the fill weight.

4. Stop fill: When the exact net weight is reached, the valve or pump shuts off and the dispenser closes. Often an anti-drip device prevents extra spillover.

5. Container removal: The filled container is removed for sealing or labeling, and the next empty one is filled.

This feedback-driven method works regardless of product density or viscosity. The filling sequence can be very fast and automated, yet guarantees each package meets the weight specification. In effect, the machine is “smart”: it adjusts fill time and flow rate based on real-time weight feedback, ensuring minimal overfill.

Types of Weighing Filling Machines

Weighing fillers come in several specialized configurations to suit different products and containers. Common types include:

● Vibratory (Linear) Weigh Fillers: Ideal for powders, granules and small pieces. These machines use a vibratory feeder to move product from the hopper into individual weigh hoppers, where each portion is weighed before discharge. By adjusting the vibration, they control flow into each container. Vibratory weighers are compact and reliable for free-flowing bulk solids.

● Net Weight (Static) Fillers: These are the classic weigh fillers. Each container is filled until its weight reaches the set target, ensuring net weight accuracy. The machine first records the empty container’s tare, then dispenses product and subtracts tare to achieve precise net fill. Net weight fillers are common in food, chemical, and agricultural packing, where exact weight is critical.

● Auger Weigh Fillers: Designed for powders and fine granules. An auger screw in a cylinder meters product into the container while a load cell underneath checks the weight. As the auger turns under motor drive, material is fed steadily and the scale stops the screw at the correct weight. This method is very accurate for free-flowing powders like flour, spices, or chemicals, and is widely used in food and pharma sectors.

● Semi-Automatic Weigh Fillers: These require some manual intervention. An operator places each container on the scale and initiates the fill (often via a foot pedal or button). Once the target weight is reached, the machine stops automatically. Semi-automatic fillers are lower-cost and flexible, suitable for small batches or low-speed lines where full automation isn’t needed.

● Bulk (Case/Tote) Weigh Fillers: These are heavy-duty systems for large containers (boxes, plastic bins, drums or totes). For example, a conveyorized bulk weigh filler automatically indexes empty cases or bins, then opens a valve to fill each one to the specified weight. These machines can fill large corrugated boxes, drums or totes with product by weight, often at rates of dozens of containers per hour. Bulk weigh fillers are common in food ingredient, pet food, and agricultural packaging (e.g. filling 5–50 kg bags by weight).

● Gravity (Linear) Weigh Fillers: In some designs, product is simply allowed to flow by gravity through a weigh hopper into the container. These linear weighers fill very quickly and work well for free-flowing liquids or granules. They are called “linear” because containers move linearly under the product outlet. For example, liquid gravity fillers (sometimes called open-mouth weigh fillers) use gravity pressure to pour liquid into a container and a scale to stop at the weight target. These systems boast high speed and precision, but they require free-flowing products (sticky or lumpy materials can clog the gravity feed).

Multi-Head (Combination) Weighing Machines

Modern weigh filling can also use multi-head combination weighers (often called multihead weighers or combination scales) for very high throughput. In these machines, a bulk feed conveyor deposits product into a center hopper from which multiple weigh heads (typically 8, 10, 14, or more) each dispense a portion on individual scales. The controls then select a combination of heads whose summed weights exactly match the target fill weight. When triggered, all selected heads discharge simultaneously into the package. This multi-head approach achieves extremely high speed (hundreds of fills per minute) and still guarantees precise weight. Multihead systems are common in snack, candy, and frozen-food packing lines, where small portions must be weighed extremely fast.

Weighing Fillers vs. Other Filling Technologies

| Filling Type | How It Works | Best For | Pros | Cons |

|---|---|---|---|---|

| Net Weight (Weigh) Fillers | Dispense product until a scale reaches a set weight. Container sits on a load cell, and the fill stops automatically at the target weight. | Liquids or solids requiring exact weight (e.g. chemicals, food). | Precision: Exact net weight per package. Flexible: Works with varying viscosities and densities. Waste reduction: Minimizes overfill. | Slower cycle time (must weigh each container). Higher cost: Scale and controls add expense. |

| Volumetric (Piston/Flow) Fillers | Dispense a fixed volume or volume proportional to pump strokes (e.g. piston draws a set volume). Often calibrated for consistent fluid volume. | Uniform liquids or suspensions sold by volume (beverages, dairy). | Speed: Can be very fast, ideal for high-speed bottling. Simplicity: Well understood for same-density products. | Less accurate for changing density or container variations. Potential waste: May overfill if product density changes. |

| Gravity/Pressure Fillers | Product flows into container by gravity (or is pushed by air/pressure) without weighing. A float valve or timer controls fill level. | Thin, free-flowing liquids (water, juices, detergents). | Cost-effective: Simple design for low-viscosity fluids. High speed: Fast when product flows easily. | Accuracy limited: Less precise for foamy or viscous products. Product dependency: Best only for fully free-flowing materials. |

| Vacuum/Siphon Fillers | Creates vacuum or pressure differential to draw liquid into containers. Often timed or level-controlled. | Foamy or viscous products (sauces, creams). | No electrical components in product path: Good for foaming products. Gentle fill: Useful for delicate liquids. | Moderate accuracy: Relies on timing, not weight. Complex maintenance: Vacuum pumps and seals. |

Table: Key differences between weigh filling machines and other common fillers.

In summary, weigh-fillers trade some speed for unmatched weight accuracy. Unlike volumetric or gravity fillers that rely on fixed volume, weigh fillers dynamically adjust the fill to suit the exact density of each batch, making them indispensable when precision is the top priority.

Key Components of a Weighing Filling Machine

A typical weighing filling machine contains several essential parts:

● Bulk Hopper or Reservoir: Holds the product (liquid, powder or granules) in bulk before filling.

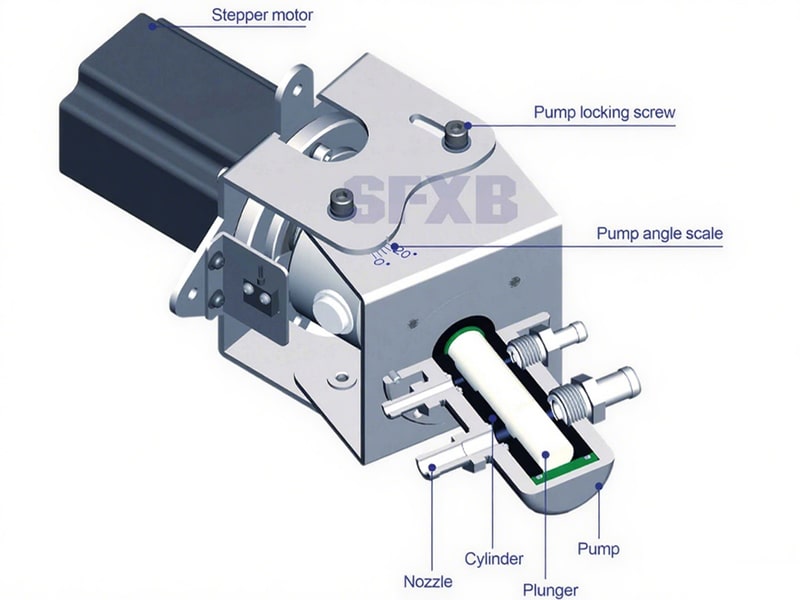

● Feeding Mechanism: Gravity chutes, vibratory conveyors or pumps that move product from the hopper toward the scale or fill valve.

● Weighing Sensor (Load Cell): A precision scale element under each container or filling head that measures the actual weight of dispensed product.

● Discharge Nozzle or Valve: Controls the flow of product into the container. The control system signals this to open/close or adjust flow.

● Control System (PLC/HMI): The “brain” of the machine. A PLC (Programmable Logic Controller) and user interface monitor the load cell output, execute the two-stage fill (fast + slow feed), and stop filling at the target weight.

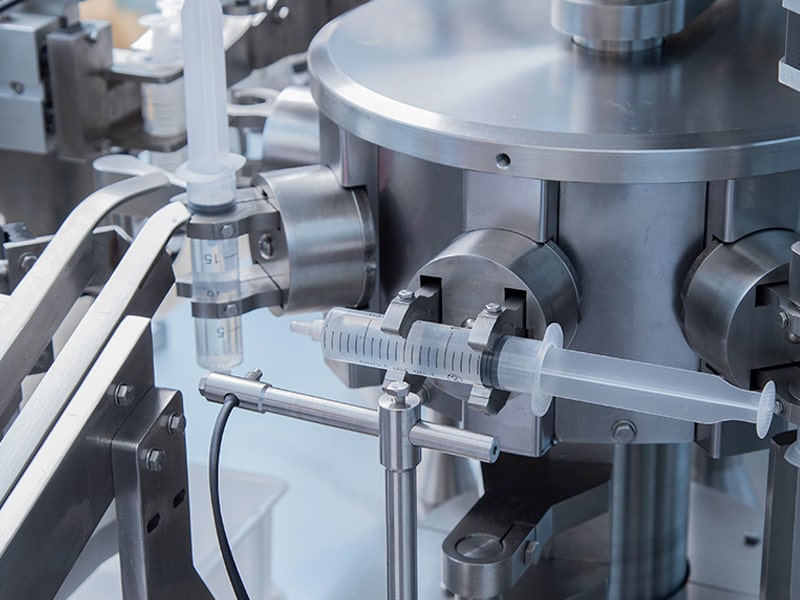

● Container Handling: Conveyor belts, indexing tables or turntables position containers under the filler. Often includes a platform scale or arm scale as part of the conveyor.

● Auxiliaries: May include valves for anti-drip, level sensors in hoppers, mechanical mixers (for slurry), and CIP (clean-in-place) spray systems for sanitation. All parts in contact with product are typically stainless steel (316L for food/pharma hygiene).

These components work together: product is fed into the dispense valve, the load cell continuously reads the weight, and the control system modulates the feed rate and stops at the setpoint. Some designs even offer multi-head scales or in-line check-weighers for added speed and verification.

dustries Using Weighing Filling Machines

Weigh-fillers are used in many sectors because of their versatility and accuracy. Common industries include:

● Food & Beverage: Sauces, cooking oils, jams, dairy and beverages require precise fill weights. Manufacturers use weigh-fillers for bottles, jars, and large food bags.

● Pharmaceutical: Pills, tablets, powder mixes and injectable liquids are filled by weight to meet strict dosing regulations. Even nutraceuticals and supplements (gummy vitamins, protein powders) are packaged using weigh-fillers.

● Chemical: Industrial chemicals, solvents, acids and paints are often batch-filled into pails, drums or totes by weight for safety and consistency. The precise dosing of hazardous materials (like pesticides or cleaning fluids) ensures safety and minimizes waste.

● Agriculture: Fertilizers, animal feed, seeds and soil amendments are filled into bags or large bins. A little mistake in a fertilizer bag can affect crop yields, so weigh-fillers ensure each bag has the exact prescribed weight.

● Cosmetics & Personal Care: Lotions, creams, shampoos, and bath products in bottles or tubs must be consistent batch-to-batch. Weigh-fillers guarantee the quality consumers expect.

● Mining & Minerals: Coal, ore, and minerals are often bagged by weight. Weigh-fillers can handle open-mouth bag filling for heavy bulk products.

In short, any product sold or regulated by weight can benefit from a weigh filler. They are especially valued in industries where over/under-filling risks compliance issues, profit loss, or customer dissatisfaction.

Compatible Container Types

Weighing filling machines can work with a wide range of containers – from small jars to large barrels. Typical compatible containers include:

● Bottles and Jugs: Glass or plastic bottles (from a few milliliters up to 5–30 liter jugs). Many liquid weigh-fillers handle 1–5 gallon bottles and canisters.

● Jerrycans and Pails: Rigid plastic or metal pails (10–30 L) and jerrycans are common, especially in chemical and food industries.

● Drums (Barrels): Standard 200 L (55 gallon) steel or plastic drums for oils, chemicals or bulk liquids. Weigh-fillers can accurately fill these heavy containers to exact net weight.

● Intermediate Bulk Containers (IBCs): Large tote tanks (up to \~1,000 L) used in chemicals or food ingredients. Industrial weigh-fillers can lift and weigh an entire IBC as it fills.

● Open-mouth Bags/Boxes: Heavy-duty bags (poly-woven, paper) for powders or granules can be filled on bag scales. Cardboard boxes or plastic tubs (for bulk solids) are also filled by weight.

● Smaller Packaging: Some weighers integrate with smaller packaging machinery – for example, filling pouches or stand-up bags on a form-fill-seal line by weight.

By design, a weigh filling line can be configured with conveyors, lift tables or fixtures to handle virtually any container geometry. The core requirement is simply that each container can be placed on the scale or weigh platform so the machine can measure its increasing weight during filling.

Advantages of Weigh (Weighmetric) Filling Machines

Using a weigh (net-weight) filler offers several important benefits over other methods:

● High Accuracy & Consistency: The machine ensures each package contains exactly the target weight. This consistency is vital for product quality and regulatory compliance, and it prevents costly overfill.

● Reduced Product Waste: Because fills stop at the precise weight, excess giveaway is minimized. Over time this can save significant material costs and improve yield.

Automation & Speed: Modern weigh fillers automate what would be a very tedious manual task. They can run at high throughput (especially multi-head models) while reducing labor.

● Versatility: A single weigh-filler system can often handle liquids, powders, granules or pastes by switching out modules or heads. It can fill different container types and sizes with simple changeovers.

● Adaptability to Product Changes: Because filling is by weight, changes in product viscosity or density do not affect accuracy. The same machine will fill correctly whether the product is slightly thicker or thinner, a clear advantage over fixed-volume fillers.

● Improved Quality Control: Automatic load-cell feedback means immediate detection of mis-pours or clogs. Many systems integrate check-weighers downstream to reject any packages that deviate from weight specifications.

● Regulatory Compliance: Many regions require weight-based labeling for packaged goods. A weigh filler inherently meets these standards by design.

Overall, weigh-filling machines deliver precision, efficiency and cost savings. They help manufacturers meet label claims and maintain a reliable brand reputation by ensuring every product is filled correctly.

Buyer’s Guide: Choosing the Right Weigh Filling Machine

When selecting a weighing filling machine, consider several key factors to match the equipment to your production needs:

● Product Characteristics: Viscosity, particle size, abrasiveness and foaming all matter. Very thin liquids, thick pastes and powders may require different fill mechanisms (gear pump vs. piston vs. vibratory). You’ll need a machine head suited to your product – for example, an auger feeder for powders, a gear pump for low-viscosity liquids, or an electromagnetic flow pump for corrosive fluids.

● Fill Range and Container Size: Identify the minimum and maximum fill weights. For small micro-fills (grams), a high-resolution scale is needed; for large fills (tens of kilograms), you need a heavy-duty scale and stable platform. Also consider container volume and shape: can the line accommodate bottles, drums or bags you use?.

● Required Accuracy: Determine the allowable weight variance. Some industries demand ±0.1% accuracy (e.g. pharmaceuticals); others may allow ±0.5% or more. Higher accuracy machines (multihead, high-resolution scales) can cost more, so align the machine’s performance with your quality specs.

● Throughput (Speed): How many containers per minute/hour must be filled? If you need very high speeds, look into multi-head weighers or multiple fill heads. For medium speeds, a single-head intermittent weigh filler may suffice. Note that weigh-fillers often run slower than simple volumetric fillers due to the time needed to settle weight, so be sure to size the machine to meet your line output.

● Automation & Integration: Do you need a standalone filler, or should it integrate into a larger line (with bottle rinsers, cappers, labelers)? Decide if you want manual, semi-automatic, or fully-automatic (continuous) operation. Also consider programmability (batch recipes, remote monitoring, etc.) and how the PLC will interface with your systems.

● Material of Construction: For food, pharma or corrosive chemicals, the machine should use FDA-approved materials (316L stainless steel contact parts, sanitary fittings). For explosive dust or vapors, ensure ATEX or explosion-proof compliance.

● Changeover and Cleaning: How easy is it to switch between products or containers? Quick-release nozzles, load-cell auto-taring, and open design for cleaning will reduce downtime. For liquid or sticky products, CIP capabilities might be important.

● Budget & Total Cost of Ownership: Besides the machine’s purchase price, factor in maintenance, energy consumption, and spare parts cost. More complex multi-head systems have higher initial cost but may justify themselves by speed and waste savings. Sometimes a simpler semi-auto filler is more economical if volumes are low.

● Supplier Support: Choose a reputable manufacturer who offers good service, training and spare parts availability. Weighing machines rely on precise scales and controls; long-term accuracy depends on calibration and maintenance support.

|

| XBCZG-8A Automatic weighing filling machine

Food, medicine, cosmetics, chemical industry and other drum-type liquid weighing sub-packaging |

By carefully weighing (no pun intended) these considerations, you can select a weigh filling system that fits your product type, throughput, accuracy needs, and budget. Remember that weigh-fillers excel when consistency and regulatory compliance are top priorities.

Frequently Asked Questions (FAQs)

1. What is a Weighing Filling Machine and how does it differ from volumetric fillers?

A Weighing Filling Machine (also called a net weight filler or weigh filler) measures the exact weight of product dispensed into each container using a load cell. Unlike volumetric fillers that deliver a fixed volume (e.g. piston or flow-meter based), weigh fillers adjust the fill based on real-time weight feedback. This ensures precise net weight, reduces giveaway, and maintains regulatory compliance.

2. Which industries benefit most from Net Weight Filling Machines?

Net Weight Filling Machines excel in any sector where accuracy and consistency are critical. Typical industries include:

● Food & Beverage: oils, sauces, powders, and beverages

● Pharmaceutical & Nutraceutical: liquid medicines, supplements, and powders

● Chemical & Agrochemical: solvents, pesticides, fertilizers

● Cosmetics & Personal Care: creams, lotions, shampoos

Their ability to handle liquids, pastes, granules, and powders makes weighers highly versatile.

3. What container types work with a Weighmetric Filling Machine?

Weighmetric Filling Machines can be configured for a wide range of packaging:

● Bottles & Jugs: plastic or glass, small to multi-liter sizes

● Drums & Barrels: 20–200 L steel or plastic

● Intermediate Bulk Containers (IBCs): up to 1,000 L totes

● Bags & Boxes: open-mouth bags for powders, flexible pouches

Adaptable fixtures and conveyor scales allow quick changeovers between formats.

4. How accurate is a Weigh Filler?

Most advanced weigh fillers achieve accuracy within ±0.1–0.3% of the target weight. Accuracy depends on factors like scale resolution, fill mechanism (auger, pump, gravity), and material properties. For high-precision needs (e.g., pharmaceuticals), multi-head weigh solutions can deliver extremely tight tolerances.

5. What should I consider when choosing a Weighing Packaging Machine?

Key selection criteria include:

● Product characteristics: viscosity, density, particle size

● Fill range: minimum and maximum net weight required

● Throughput: containers per minute or hour

● Required accuracy: allowable variance (e.g., ±0.2%)

● Automation level: manual, semi-automatic, or fully integrated line

● Sanitation & compliance: material of construction (e.g., 316L stainless steel), CIP features

Evaluating these factors ensures you select the right Weighing Filling Machine to meet production goals and budget.

| References: | |

| 1. | Analysis and Optimal Targets Setup of a Multihead Weighing Machine ——Retrieved from: arXiv |

| 2. | Design Analysis of Filling and Weighing Machine in Milk Powder Plant of Dairy Industry Using Load Cells and Conveyor System –Retrieved from: Academia |

Comments