Flexible packaging refers to packages or containers made from easily yielding materials (plastic films, paper, foil, etc.) that can change shape to fit their contents. This versatile format includes products like bags, pouches, wraps, liners, and sleeves – from small snack pouches to large industrial sacks. The industry has grown rapidly: in the U.S. alone flexible packaging sales reached $42.9 billion in 2022 (a 15.3% increase over 2021), making it the second-largest packaging segment behind paper and paperboard. Flexible packaging is prized for innovation in product protection, design, and sustainability, and it impacts the environment, consumers, and businesses in positive ways.

Flexible packaging may be constructed from any combination of materials – such as plastic films, aluminum foil, and coated papers – to provide a high level of barrier protection with minimal material. These layers are laminated together (often with adhesive or extrusion processes) to create a thin, flexible film. Because flexible packages use much less material than rigid containers, they weigh less and consume less water and energy to make. In practice, this means a flexible bag or pouch can protect a product just as well as a box or can, but with far lower material and transport cost. For example, one expert notes that switching to flexible film “often reduces the number of steps — and hence the number of machines — on a packaging line” compared to rigid formats.

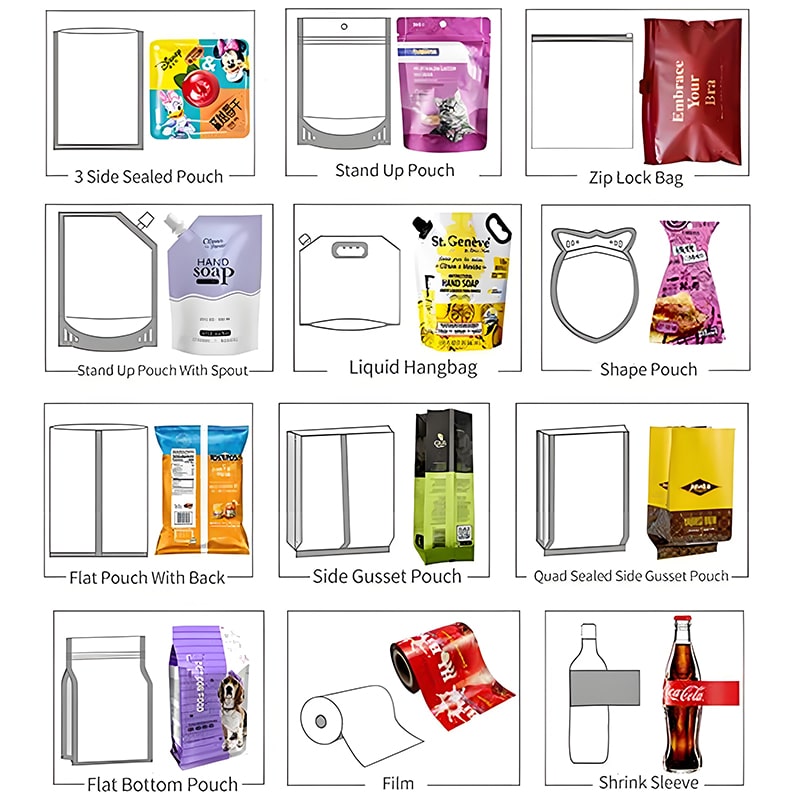

Types of Flexible Packaging

Flexible packaging comes in many formats, each suited to different products and production processes. Common types include:

- Stand-Up Pouches: Self-supporting resealable bags that stand upright on shelves (often with zipper locks, spouts, or sliders). They are widely used for foods (snacks, coffee, pet food), detergents, and other consumer goods.

- Lay-Flat Pouches: Flat bags that expand when filled. These are efficient for storage and shipping (they lie flat when empty) and are commonly filled by form-fill-seal machines. They can include features like hang-holes or tear notches.

- Rollstock Film: Continuous rolls of printed and laminated film (called rollstock) that are later formed into bags or used as overwraps. Rollstock is fed into vertical form-fill-seal (VFFS) or horizontal form-fill-seal (HFFS) machines to create and fill packages on the fly.

- Laminated Films and Overwrap: Flexible films used as liners inside boxes or as overwraps around trays and multipacks. They provide a tight seal and barrier (e.g. blister packs or flow-wrapped items).

- Shrink and Vacuum Bags: Heat-shrinkable films that shrink tightly around a product when heated (common for meat and produce), and vacuum bags that remove air to protect products from spoilage.

- Heavy-Duty Bags: Large flexible sacks made of thick plastic or woven materials, used for industrial goods (fertilizer, salt, pet food). These often include features like die-cut handles and tear notches for easy handling.

For heavy or bulk items, robust poly bags are used. The image above shows a heavy-duty plastic bag with a die-cut handle and tear-notch – a common flexible packaging for bulk salt or soil conditioner. Even large volumes (50 lbs or more) are handled in flexible packages that can be lifted and carried, demonstrating the versatility of flexible formats for a range of products.

Advantages of Flexible Packaging

Flexible packaging offers many benefits over traditional rigid containers, driving its popularity across industries:

- Extended Shelf Life: Multi-layer flexible films provide excellent barrier properties (against moisture, oxygen, and light), which helps preserve freshness. Studies show that flexible packaging extends the shelf life of many products (especially foods) and maintains quality for longer periods. For example, a snack pouch can keep chips crispy by blocking out air and moisture better than a paper bag.

- Consumer Convenience: Flexible packages are lightweight and easy to carry. Many designs include convenient features like resealable zippers, spouts, tear-notches, and handles. These features make the package easy to open, reclose, transport, and store. For instance, a stand-up pouch with a zipper lets consumers use part of the product and reseal it for later, which increases satisfaction. Overall, this consumer convenience drives repeat purchases.

- Lower Costs: Using thinner films and fewer materials means lower production and shipping costs. Flexible packages are often less expensive to produce than comparable rigid containers. They are lighter and take up less space in trucks and warehouses, reducing transportation fuel use and storage costs. In fact, Packaging Digest notes that flexible packaging can use “less material than rigid alternatives” and requires “less space” in storage and on shelves. This efficiency directly improves a company’s bottom line.

- Sustainability: Because they use minimal material and energy, flexible packages generate less waste overall. They typically require much less water and fewer raw resources to manufacture, and produce lower greenhouse gas emissions during production and transport. In other words, a flexible pouch often leaves a smaller carbon footprint than a bulky box or can. Packaging Digest confirms this, noting flexible packaging “generates less waste compared to rigid containers” and “requires less material and energy to produce,” leading to lower carbon emissions. These attributes align with growing environmental goals.

- Shelf Appeal: Flexible films offer excellent printing quality and design options. Brands can use vivid colors, custom shapes (e.g. stand-up pouch profiles), and clear windows to make products stand out on the shelf. Flexible packages allow the product itself to be partially visible (clear panels) or feature unique structures (like quad-seal designs) that attract consumers. Such marketing flexibility builds brand image and can boost sales.

Flexibility also means these packages can accommodate secondary packaging innovations, such as pouches within boxes, further extending branding opportunities.

Flexible vs. Rigid Packaging

Flexible packaging competes directly with rigid packaging (plastic bottles, cans, glass, cartons) in many markets. The key trade-offs are:

- Weight and Space: Flexible packages are much lighter and more compact than rigid ones. This means lower shipping costs and easier handling. For example, one analysis noted that switching to flexible film “reduces the number of steps — and hence the number of machines — on a packaging line,” implying a simpler, more efficient process.

- Material Use: Because flexible packs use thin films, they consume far less material. Rigid containers often use thick plastic or glass, which adds weight. Less material in flexible packs can translate to cost savings and waste reduction.

- Protection: Rigid containers can offer durability and are often easier to recycle, but flexible films today provide comparable barrier protection through engineered laminates. Flexible packs can resist puncture, protect against moisture, and even be designed for sterilization (e.g. retort pouches for aseptic processing).

- Recyclability: Rigid materials like aluminum and PET are widely recycled. Multi-layer flexible films are more complex to recycle because layers must be separated or made from compatible polymers. This is a challenge for the industry. Many flexible packages end up in general waste if no recycling stream exists. Recognizing this, packaging associations and companies are investing in solutions: developing recyclable mono-material films, compostable biopolymers, and dedicated film recycling programs. In short, while flexible packs are more resource-efficient in use, they require ongoing innovation in end-of-life solutions.

- Design Freedom: Flexible packaging allows shapes and features that rigid cannot. Pouches can conform to irregular product shapes, and films can be customized in size each run, unlike fixed rigid molds. This freedom makes flexible ideal for novel product forms.

Overall, flexible packaging often offers a better product-to-package ratio, but companies must balance that with emerging sustainability requirements. Many consumers and regulators now expect packaging to be recyclable, so the flexible packaging industry continues to evolve toward more sustainable films and recovery processes.

Industry Applications

Flexible packaging spans virtually every sector. Notable applications include:

- Food & Beverage: This is the largest user of flexible packaging. From chips, cereals, and coffee to frozen foods and sauces, flexible pouches and bags preserve freshness and convenience. For example, soups and sauces now come in aseptic pouches, and salad mixes are sold in zippered green pouches. Flexible packaging’s ability to extend shelf life is “particularly crucial in the food industry”. Snack packs, stand-up pouches for dried fruits, and laminated wrappers for confectionery are all flexible formats.

- Pharmaceutical and Healthcare: Sterility and protection are paramount here. Flexible films are used for medical device kits, sterile wipes, IV solution pouches, and unit-dose medication sachets. The barrier properties of multi-layer laminates keep pharmaceuticals and supplements safe from contaminants. As one source notes, flexible packages “ensure the sterility and safety of medical products” by protecting against moisture and light. Blister packs (hard film on backing) and liquid pouches (e.g. insulin pens in pouches) are common.

- Personal Care and Cosmetics: Products like lotions, shampoos, and creams use flexible tubes and pouches. Single-use sachets (for shampoo or cosmetics samples) are convenient and economical. Flexible packaging allows unique formats like easy-squeeze tubes or multi-layer laminate masks. In fact, flexible packs offer “innovative designs and user-friendly features, like easy-squeeze tubes and single-use sachets” that appeal to beauty and wellness consumers. Resealable pouches for facial masks or pet treats are also widespread.

- Pet Food: Many pet foods (especially premium dry foods or treats) come in flexible stand-up bags with zipper closures. These keep pet food fresh and make carrying/bagging easier for owners. Pet food companies frequently cite flexible packaging’s moisture-barrier and convenience features when marketing products.

- Household and Industrial: Flexible formats are used for detergents, lawn and garden chemicals, and industrial solvents. Heavy-duty plastic bags hold items like bulk cat litter or garden soil. Small satchels might contain single-dose laundry detergent pods. The ability to tailor thickness and strength makes flexible packaging suitable for a wide size range.

In each case, flexible packaging delivers the combination of protection, low cost, and convenience demanded by both brands and end consumers.

Manufacturing Process and Machinery

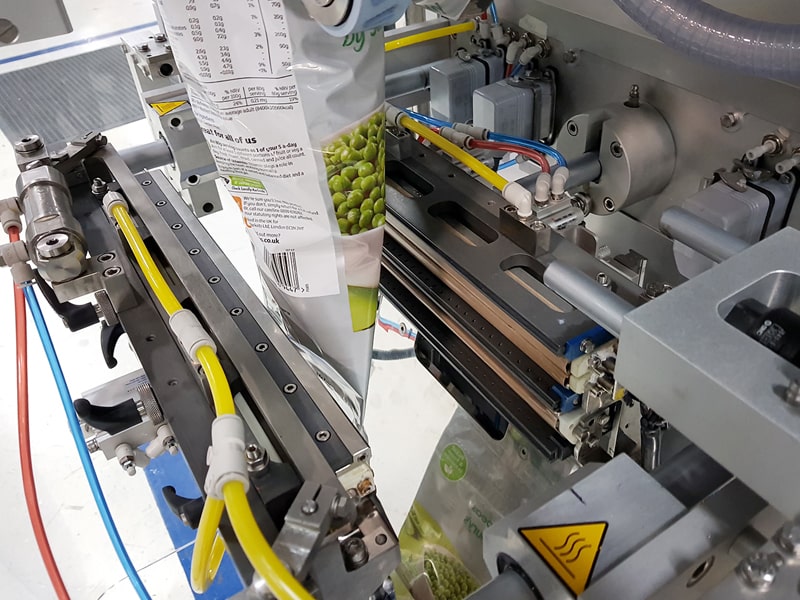

Creating flexible packaging involves several steps on specialized equipment. First, barrier films are printed (often via flexographic or gravure printing) with brand graphics. Next, these films are laminated (by adhesive or extrusion lamination) to bind multiple layers (e.g. a high-strength plastic layer with an aluminum foil for barrier). The result is a rollstock of custom film.

Converting this rollstock into finished packages uses machines like vertical form-fill-seal (VFFS) or horizontal form-fill-seal (HFFS) lines. A VFFS machine automatically forms a bag from the film, fills it with product (snacks, grains, liquids, etc.), and seals it — all in one continuous process. Horizontal machines take pre-made pouches or trays, fill them, and seal them. Additional equipment (e.g. spout inserters, pouch openers, or gas flushers) can add special features.

The image above shows an automatic bag-making and filling machine used in flexible packaging production. Modern equipment can form, fill, and seal hundreds of pouches per minute with precise control. Our company SFXB(XueBa) designs and manufactures such machines: from high-speed pouch filling lines to multi-lane baggers. Using the right packaging machinery is critical; industry analysts note that flexible formats often “reduce the number of machines on a packaging line” because one versatile machine can replace several rigid-package machines. In other words, a single form-fill-seal system can package a product that might otherwise require a rigid container filler plus a bottling line, cutting capital and labor costs.

Key machinery for flexible packaging includes:

- VFFS/Pouch Machines: These form bags/pouches from film and fill them. They handle stand-up pouches, flat pouches, or lay-flat bags.

- Bag-fillers: For pre-formed bags, vertical or horizontal bag fillers can open, fill, and close flexible bags (for example, filling open-top poly bags with powders or liquids).

- Flow Wrappers: These wrap individual items or multi-packs in flexible film (used for bars, candies, frozen foods).

- Vacuum and Shrink Sealers: Specialized machines that evacuate air and/or heat-shrink the film tightly around the product.

- Cutting/Sealing Machines: For lamination, tube sealing, or forming specialty packages (like quad-sealed bags).

By supplying these machines, SFXB helps businesses convert products into flexible packages efficiently. Our systems can be customized for different products (liquids, powders, solids) and scales (pilot lines to high-speed production).

Sustainability and Recycling

Flexible packaging is often greener than it appears. Its efficiency means less waste and emissions in use, even if recycling remains a challenge. Because flexible packs use thin films, a far higher percentage of the product’s weight is actual goods (vs. container). Less material per package means less raw resource extraction and lower shipping fuel usage. For example, one analysis found that flexible packing uses roughly 1/4 the materials of some rigid options to pack the same volume of product. In terms of carbon footprint, less plastic and aluminum per unit translates to lower production emissions. Packaging Digest confirms this advantage, noting flexible packaging “often requires less material and energy to produce” and that its lighter weight “leads to lower carbon emissions”.

However, the multi-layer films typical of flexible packaging have limited recyclability in today’s waste systems. Because films are laminated, they are hard to separate into pure resin streams. As a result, many flexible packs are not recycled curbside (though collection programs for film plastics do accept some pouches and bags). The industry is aware of this trade-off. Many manufacturers are shifting toward recyclable mono-material films (where all layers are the same plastic type) or introducing compostable films for certain uses. Recycling initiatives (like plastic bag drop-off locations) are also expanding. The Flexible Packaging Association and brands are investing in closed-loop solutions. In short, while flexible packaging uses fewer resources, it requires continued innovation in recycling and composting to fully close the sustainability loop.

Future Trends in Flexible Packaging

The outlook for flexible packaging is bright, with ongoing trends in sustainability, technology, and convenience. Key trends include:

- Eco-friendly Materials: Driven by consumer demand, companies are developing recyclable and bio-based films. For example, brands are launching flexible pouches made from paper or clear films certified as recyclable. Research into home-compostable pouches and inks is also a hot topic.

- E-commerce Optimization: As online shopping grows, flexible packaging formats (like mailer bags and reclosable pouches) are being optimized for shipping (tamper-evident, lightweight, right-sized). Custom printed film on demand (digital printing) is another growth area for short runs and customization.

- Smart Packaging: Integrating technology such as QR codes, NFC tags, or freshness indicators into flexible packages is emerging. These “smart” packages can engage consumers (e.g. scan code for product info) or monitor product quality (sensors that change color if spoiled).

- Innovative Formats: Expect more creative packages – like pouches with built-in dispensers, refillable pouches for consumer reuse, or hybrid structures combining rigid and flexible parts. Packaging Digest notes that flexible packaging innovation has been robust, with new structures and dispensers continually introduced.

- Streamlined Production: Automation and Industry 4.0 are reaching packaging. Machines with better controls, vision systems, and predictive maintenance make flexible packaging lines more efficient and reliable. Our customers benefit from these advances when we integrate automation in SFXB machinery.

Overall, flexible packaging continues to evolve as a high-tech solution for modern markets, balancing product protection with environmental concerns. Manufacturers who stay ahead of these trends can better serve consumers and brand owners alike.

Conclusion

Flexible packaging – with its combination of lightweight design, product protection, and consumer convenience – is reshaping how products are packed and shipped. It offers clear business advantages: lower costs, extended shelf life, and strong market appeal. At SFXB, we recognize these benefits and have tailored our packaging machinery to meet them. We provide advanced filling and packaging lines (vertical/horizontal form-fill machines, pouch packers, baggers, etc.) that enable clients to harness the full potential of flexible packaging. Whether your product is food, medical, chemical, or consumer goods, our equipment can efficiently create and fill the appropriate flexible package. Investing in the right machinery and materials will help any manufacturer reduce waste, cut costs, and delight customers with innovative packaging – securing a competitive edge in the market.

FAQs:What Is Flexible Packaging?

What is flexible packaging?

Flexible packaging refers to non-rigid containers made from pliable materials—such as plastic films, foils, paper, or multilayer laminates—that change shape to accommodate contents. Common formats include pouches, bags, rollstock films, shrink/vacuum bags, liners, and overwraps.

What types of flexible packaging are available?

Key types include:

● Stand-up pouches (often resealable with zippers or spouts),

● Flat or lay-flat pouches (expandable when filled),

● Rollstock film (used in form-fill-seal machines),

● Shrink and vacuum bags (for perishables or bulk items),

● Laminated overwrap and liners (for trays or multipacks).

Why do businesses choose flexible packaging?

Flexible packaging offers 7 key advantages:

1.Extended shelf life via effective barrier protection,

2.User convenience (lightweight, resealable features),

3.Cost efficiency (lower production and logistics costs),

4.Sustainability through reduced material and transport carbon footprint,

5.Attractive shelf appeal via custom printing and shapes,

6.Design flexibility for diverse products,

7.Wide industry applicability (food, pharma, personal care, pet food, industrial).

How does flexible packaging compare to rigid packaging?

● Weight & space: Flexible is lighter and takes up less volume.

● Material usage: Requires less material, improving efficiency.

● Protection: Offers comparable barrier protection via engineered films.

● Recyclability: Rigid is easier to recycle, while flexible often needs specialized recycling or mono-material innovation.

● Design: Flexible allows more shape and feature customization.

What industries commonly use flexible packaging?

● Food & Beverage (snacks, coffee, sauces, frozen foods),

● Pharmaceutical & Healthcare (sterile pouches, medical wraps),

● Personal Care & Cosmetics (tubes, sachets),

● Pet Food (resealable bags),

● Household & Industrial (chemicals, detergents, garden products).

What machinery is used to produce flexible packaging?

Production involves:

● Printing & lamination of barrier films;

● Form-Fill-Seal (VFFS/HFFS) machines to form and fill packages;

● Bag-fillers for pre-formed pouches;

● Flow wrappers for individual or multipack wrapping;

● Vacuum/shrink sealers for protection and compacting.

SFXB specializes in manufacturing such advanced packaging machinery—tailored for efficiency, automation, and diverse product types.

Is flexible packaging eco-friendly?

Yes—it generally uses less material and energy, yields lower transport emissions, and reduces waste due to higher product-to-package ratio. However, recycling remains a challenge for multi-layer films. Solutions include mono-material films, compostable alternatives, and film-specific recycling programs.

What future trends are shaping flexible packaging?

Emerging trends include:

● Recyclable & bio-based films,

● E-commerce–optimized formats and on-demand digital printing,

● Smart packaging (QR codes, NFC tags, freshness sensors),

● Hybrid packaging structures (rigid + flexible),

● Automation and Industry 4.0 integration in production machines.

How can one choose the right flexible packaging solution?

Consider:

● Product characteristics (sensitivity to moisture, oxygen, light),

● Desired shelf life, distribution method, shelf placement,

● Convenience features (resealability, spouts, handles),

● Sustainability goals and recyclability,

● Whether in-house filling or using external co-packers.

Machinery and packaging material should align with these factors for optimal performance.

How can SFXB(Xueba) help with flexible packaging needs?

SFXB offers:

● Custom-designed form-fill-seal machines (VFFS/HFFS),

● Bag-fillers, flow wrappers, vacuum and shrink sealers,

● Tailored systems for liquids, powders, solids,

● Automation-focused lines for efficiency and reliability.

● With our expertise, clients can achieve reduced costs, improved product protection, sustainability objectives, and stand-out packaging design.

| References: | |

| 1. | What is Flexible Packaging? Benefits, Trends & Sustainability ——Retrieved from:PackagingDigest |

| 2. | Flexible Packaging Market Size, Share & Trends Analysis Report ——Retrieved from:GrandViewResearch |

| 3. | Impact of Flexible Packaging on the Supply Chain ——Retrieved from:PlasticsIndustry |

Comments