Vials – small glass or plastic bottles – are ubiquitous in medicine and laboratories. They are favored for storing vaccines, injectables and reagents due to their clarity, chemical inertness and ability to be hermetically sealed. A vial filling machine automates the loading of precise liquid or powder doses into vials, dramatically speeding up production while ensuring sterility. These machines typically form part of an automated filling line that feeds, cleans, fills, stopples and caps vials in one continuous sequence. In pharmaceutical manufacturing, such systems are crucial: they achieve consistent dosing, minimize contamination risk, and help meet stringent FDA/EMA cGMP requirements.

Vial filling machines combine several functions — from vial feeding and washing to aseptic filling and sealing — to create a high-throughput, contamination-free vial packaging line. By automating repetitive tasks, they eliminate human error. For example, automated sensors and precise pump controls ensure each vial is filled to the exact target volume, virtually eliminating overfills or underfills. Integrated washing and depyrogenation tunnels remove particulates and sterilize vials (often using high heat) before filling, enabling truly aseptic vial filling conditions. With output rates ranging from dozens to hundreds of vials per minute (some lines handle 50–600 vials/min or more), modern systems dramatically boost vaccine and drug production, which was critical during pandemic vaccine rollouts.

Key Benefits: Automated vial filling delivers precision, speed and safety. Common advantages include:

● Precision Dosing: Advanced pumps and scales guarantee uniform fill volumes with accuracy often within ±0.5%. This error-free filling ensures dose consistency and patient safety.

● Sterile Processing: Hygienic design and built-in sterilization (e.g. pre-fill dry-heat tunnels and cleanroom operation) mean each vial is filled in a contamination-free environment. The entire line can run in an ISO-classified cleanroom with HEPA filtration, or inside isolators/RABS, to meet strict sterility standards.

● High Throughput: Integrated conveyors, multi-head fillers and rapid capping stations allow high-speed vial filling – from pilot scales to commercial runs. For example, lines may process up to 36,000 vials per hour. This throughput accelerates time-to-market for vaccines and biologics.

● Regulatory Compliance: By design, these machines support cGMP guidelines. Automated cleaning (CIP/SIP), validated protocols and barrier systems help meet FDA/EMA requirements. Advanced systems even perform 100% in-process control (weighing each vial before/after fill) to verify compliance on every unit.

● Versatility: Quick-change parts let one line handle different vial sizes, shapes and formulations. From water-like solutions to viscous suspensions, modern machines accommodate all viscosities. The same equipment can switch between liquid vaccines, serums, oily tinctures or even lyophilized (freeze-dried) powders as needed.

● Quality Assurance: In-line inspection systems (cameras, sensors and weight checks) catch defects immediately. Every vial can be checked for correct fill level, stopper and cap integrity or particulate matter. This automated QC greatly reduces product recalls.

Core Steps in a Vial Filling Line

Automated vial filling is a multistage process with tightly coordinated steps. A typical line performs the following sequence, each step handled by dedicated equipment:

● Vial Feeding: Empty vials are loaded (manually or with unscramblers) onto a conveyor or carousel in upright position. This feeder spaces and orients vials for subsequent operations.

● Vial Washing: The first processing station thoroughly cleans vials. High-pressure water or WFI (Water for Injection) sprays and air jets flush both the interior and exterior of each vial to remove dust, residues or particulates.

● Sterilization (Depyrogenation): Washed vials enter a hot-air tunnel (typically 200–400 °C) to achieve depyrogenation. This destroys bacteria, spores and endotoxins, ensuring vials are sterile. Dry-heat sterilization is standard for glass containers.

● Filling: Sterile vials move to the filling station where liquid drug is dispensed. Using precision pumps and nozzles, the machine delivers a measured volume of medication into each vial. Contemporary fillers use technologies such as rotary piston pumps, peristaltic pumps or time-pressure dispensers to ensure exact dosing (discussed below). All filling is done under aseptic (sterile) conditions to protect the product.

● Stoppering: Immediately after filling, a stoppering machine inserts rubber or silicone stoppers into the mouth of each vial. Automated pick-and-place or continuous stoppering systems locate and push stoppers to seal the vial. This step often includes nitrogen “capping” (gassing) to reduce oxygen headspace for sensitive biologics.

● Freeze-Drying (Optional): For injectable powders, partially stoppered vials are loaded into a lyophilizer (freeze-dryer) after filling. The lyophilizer freezes the product and removes water under vacuum, stabilizing temperature-sensitive formulations. Many filling lines include an integrated freeze-dry tunnel for such processes.

● Capping/Sealing: After stoppering (or after lyophilization), vials are capped. A vial capping machine applies aluminum flip-off or plastic caps over the stopper. The machine orients caps via a vibratory bowl, places them on the vial, then uses spinning or pressure rollers to crimp them securely. This permanent seal prevents leaks and tampering.

● Inspection & Labeling: In the final stage, each sealed vial is inspected by cameras or sensors for defects (e.g. incorrect fill, missing stopper, cap misalignment) and weight-checked for accuracy. Defective units are rejected. Finally, an inkjet or label applicator adds product information (lot number, expiry, etc.) on the vial. Labeled vials are then collected for packaging.

Each of these steps relies on precision machinery and sensors to maintain product quality and throughput. The entire vial filling line is often enclosed or operated under laminar flow/isolator conditions to preserve sterility.

Types of Vial Filling Systems

Vial filling equipment comes in many configurations to suit different production scales and applications. Key varieties include:

● Desktop/Benchtop Machines: Compact “laboratory” fillers (sometimes called benchtop or small-dose machines) serve R&D labs or pilot production. For example, ceramic-pump desktop fillers can handle small batches (dozens of vials per minute) of injectables or cosmetics. These units often integrate filling and capping in one cabinet and are portable or table-top.

● Semi-Automatic vs. Fully Automatic: Some systems are semi-automatic: an operator loads trays of vials and the machine performs filling and capping. Fully automatic lines include unsramblers and conveyors, requiring minimal manual intervention. Automatic models can integrate feeders, washers, fillers, stoppers and capper in one continuous assembly line for hands-off operation.

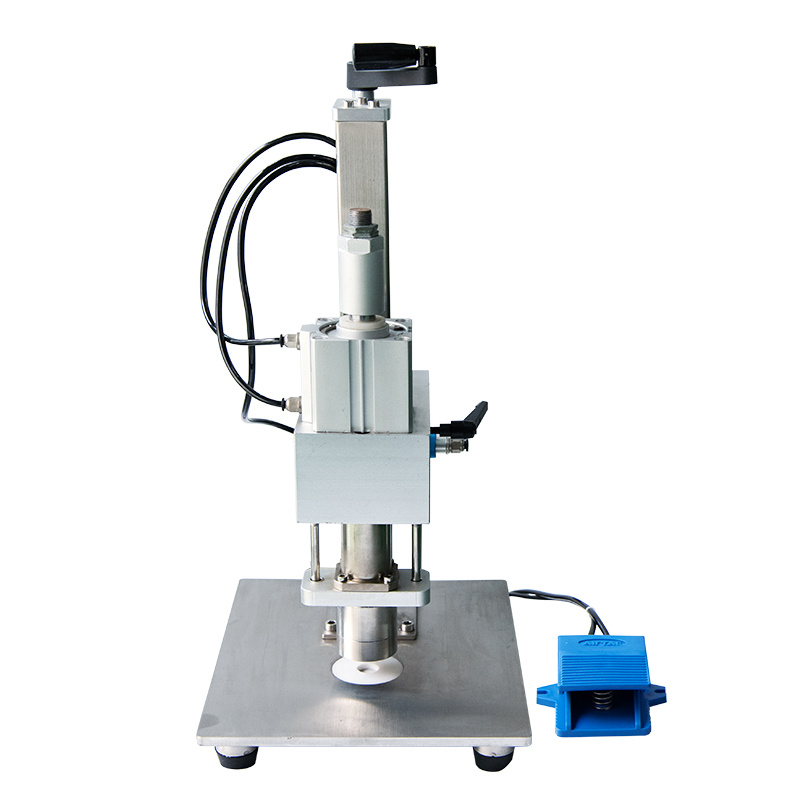

|

| XBZG-50 Semi-automatic Vial Capping / Crimping Machine |

● Integrated Filling Lines: Large production lines combine all steps end-to-end. For instance, a vial filling and stoppering machine might fill and stopper in one module, followed by a separate capping and labeling module. These lines are highly customizable (modular) and often meet ISO cleanroom standards. Some designs, such as modular isolator systems, allow assembly of multiple machines into a single sterile enclosure.

● Rotary vs. Linear Configurations: Vials can be processed on rotary wheels (spinning turntables) or linear conveyors. Rotary fillers often offer higher speeds and compact layouts for large batches. Linear machines are more flexible for changeovers and maintenance. Both types achieve high precision, but layout choice depends on factory needs.

● Lyophilization-Ready Systems: Many advanced fillers include an integrated lyophilization (freeze-dry) chamber for products that require powder filling. The line can feed filled vials directly into a connected freeze dryer, and then continue to cap and label dry-filled products without manual transfer. This arrangement saves space and maintains sterility.

● Ampoule & Other Formats: Though this article focuses on vials, similar machines exist for filling ampoules and syringes. Some vial lines can be adapted (with format change parts) to handle ampoules or tubes. The term “ampoule and vial filling machine” refers to these hybrid designs that can fill multiple container types.

Overall, options range from automatic vial filling and capping machines to complete vial packaging lines (including printing and case-packing). Small vial filling machines are a cost-effective entry point for small-volume production, while fully automated vial packaging machines serve high-throughput needs.

Filling Technologies and Pumps

Precise vial filling depends on the choice of dispensing technology. Common filling systems include:

● Rotary Piston Pump (RKP): A positive-displacement pump where fluid is drawn into a chamber by a rotating piston. RKPs can handle a wide range of viscosities, from water-like to syrupy, with high accuracy. The rotating piston continuously meters liquid, making it ideal for continuous and repeatable filling of vials.

● Peristaltic Pump (PP): In this tubing-based pump, rollers squeeze a flexible tube to draw liquid and then push it out. Because the liquid only contacts the sterile tubing, peristaltic pumps minimize contamination risk. They are suitable for delicate biologics or solvents. Accuracy is high when properly calibrated, and tube wear can be managed through routine maintenance.

● Rolling Diaphragm Pump (RDP): This pump uses a flexible diaphragm that rolls inward and outward to move fluid. Similar to peristaltic pumps, the product only touches the diaphragm, providing excellent chemical compatibility and sterilizability. RDPs are well-suited for sterile media and can achieve very tight dosing tolerances.

● Time-Pressure Filler (TPF): A bulk tank is pressurized, and electronic valves open for a calculated time to fill each vial. The fill volume depends on pressure and time. TPF is simple and fast, often used for free-flowing liquids where ultra-high precision is less critical. However, modern TPF systems incorporate sensors to improve accuracy for pharmaceutical use.

● Mass Flow (Volumetric) Systems: Not detailed in the sources above, but often used: gravimetric or mass flow metering ensures fill weight accuracy by measuring weight directly. These systems often complement the above pumps for final QC.

|

| XBGB-20 Desktop vial filling production line (bottle feeding/stoppering/capping/capping) |

Many advanced lines combine multiple pump types (for example, a rotary piston pump for viscous products and a peristaltic pump for aqueous solutions) in a combi filler. The goal is always ultra-precise dosing – as one source notes, “there are no fill differences in product batches” with modern automation.

Maintaining Sterility

Sterility is the top priority in vial filling. To prevent contamination, manufacturers employ multiple safeguards:

● Cleanroom Environment: Vial filling typically occurs in ISO Class 5 (Grade A) or 7 (Grade B) cleanrooms or isolator setups. High-efficiency filters and positive pressure air flow keep particulates out of the filling zone.

● Sterilization of Components: All contact parts (pipes, nozzles, valves) are sterilized by methods like SIP (steam sterilize-in-place) or gamma irradiation. Tools are made of stainless steel or inert materials (e.g. ceramic plungers) to withstand sterilization. Pre-sterilized vials, stoppers and caps are often supplied in trays or tunnels to avoid any outside contamination.

● Barrier Systems: Fillers are frequently enclosed in barrier isolators or RABS (Restricted Access Barrier Systems). Operators load materials through glove ports, and machine interfaces are designed for easy sterilization. This physical separation keeps airborne microbes away.

● Validated Procedures: Every cleaning and sterilization step is validated (with biological indicators) to ensure >10^-6 sterility assurance. Processes are documented to comply with 21 CFR Part 11 and Annex 1 guidelines.

Together, these measures enable aseptic vial filling. For example, after washing and sterilizing, vials might be fed through a sterile tunnel or robotic transfer, so they are never exposed to the open air until sealed. The result is pharmaceutical-grade sterility: studies report “no microbial presence” in the filling environment after proper sterilization.

Quality Control & Inspection

Quality control is built into modern vial filling lines. In-process controls (IPC) may include:

● Weight Checks: As mentioned, many systems weigh each vial before and after filling. A cited source notes that 100% weight-based IPC is standard, ensuring “check the filled content precisely”.

● Vision Inspection: High-speed cameras scan vials for fill level, stopper position, cap integrity, and labels. Automated systems can flag underfilled, overfilled or missealed vials instantly.

● Gas Integrity: Especially for critical drugs, headspace oxygen and pressure can be measured (e.g. high-voltage leak detection for caps).

● Software Monitoring: Data from all sensors is logged for review. Alarms are triggered for any deviation.

These QC steps dramatically reduce the chance of shipping a bad product. In practice, lines achieve near-100% first-pass quality, letting manufacturers meet strict recall thresholds. As one industry guide states, integrated inspection units “lower the probability of product recalls”.

Industry Applications

Vial filling machines are used across many sectors where small-volume sterile packaging is needed:

● Pharmaceuticals: By far the largest user. Life-saving drugs (vaccines, antibiotics, biologics, IV injectables) are routinely filled in vials. The precision and sterility of vial fillers make them ideal for parenteral formulations.

● Biopharmaceuticals: For biotech therapeutics (monoclonal antibodies, cell/gene therapies), maintaining product purity is vital. Fillers that can gently handle high-value biologics under aseptic conditions are indispensable.

● Biotechnology & Research: Diagnostic reagents, buffers and lab chemicals are often aliquoted into vials. Fillers are used in biotech labs and pilot plants to dispense enzymes, antibodies and molecular biology reagents into sterile vials. (Even universities and R&D groups use bench-top fillers for small batches.)

● Veterinary Medicine: Veterinary vaccines and drugs for pets/farm animals are increasingly packaged in vials. Automated vial fillers ensure veterinary injectables meet the same safety standards as human drugs.

● Cosmetic & Personal Care: High-end cosmetics (e.g. hyaluronic acid serums, beauty injectables like Botox) are sold in glass vials. Cosmetic manufacturers use vial filling lines to dose these sensitive liquids and ensure sanitary sealing.

● Chemicals & Specialty Fluids: Some non-pharma industries adopt vial-filling systems. For instance, manufacturers of agricultural pesticides, flavors, or electronic cigarette oils use similar fillers for corrosive or high-value liquids.

● Food & Nutraceuticals: A few lines fill concentrated flavors, enzymes, or probiotic suspensions into vials or similar small bottles, leveraging the precision filling technology from pharma.

In summary, any industry that needs precision-dosed, sterile packaging of small volumes may use vial filling machines.

Leading Manufacturers and Solutions

Global equipment providers offer a range of vial filling solutions. Systems range from benchtop fillers to fully integrated production lines. Top suppliers design machines that comply with ISO standards and can be customized (e.g. modular designs to handle different vial formats). For example, one provider notes that their compact vial fillers can produce liquids, semi-solids or powders in sterile cleanrooms. Another reports that their lines span speeds from 10 to 600 vials/min with tool-less changeovers. Many vendor sites emphasize versatility (filling anything from vaccines to cosmetics) and advanced features like 100% fill checks.

Key factors when choosing a system include required output rate, container formats, level of automation, and compliance features. Customary options include servo-driven motion for high speed, multi-head filling arrays, integrated stopper/vial handling, and complete track-and-trace capability. Service and validation support are also essential, as pharmaceutical firms must qualify equipment for GMP use.

Cost Considerations: Pricing varies widely. A simple benchtop filler may cost a few tens of thousands of dollars, whereas a complex aseptic filling line can run into the hundreds of thousands or more. Price depends on throughput, cleanroom/isolation features, custom automation and local regulations.

Future Trends and Innovations

The vial filling machine industry continues to evolve. Current trends include:

● Flexibility & Speed: Demand for faster format changeovers (for multi-product facilities) is rising. Machines with quick-connect cassettes and automated format change are more common.

● Containment & Safety: High-potency drugs (OEB 5) require enhanced containment. Isolator-based fillers and single-use (disposable) fluid paths are growing.

● Smart Manufacturing: Integration with Industry 4.0 – data analytics, remote monitoring and predictive maintenance – is on the rise. Real-time data from sensors can optimize yield and troubleshoot issues before they cause downtime.

● Environmental Impact: Some manufacturers are exploring more sustainable designs, such as solventless cleaning (reducing water use) and waste reduction in buffer (as smart fill algorithms waste less liquid).

● Global Standardization: As emerging markets invest in biotech, standardized vial filling solutions that meet global GMP are becoming a priority.

Overall, advances in precision engineering and automation make modern vial filling machines highly reliable and efficient. By combining aseptic processing with Industry 4.0 technologies, these machines ensure that patient-critical injectables reach the market safely and quickly.

Frequently Asked Questions (FAQ) about Vial Filling Machine

1. What is a vial filling machine?

A vial filling machine is an automated system used to precisely fill glass or plastic vials with liquid or powdered products. It typically integrates vial feeding, washing, sterilization, filling, stoppering, capping, and inspection into a continuous line, ensuring high accuracy, speed, and sterility.

2. Why is aseptic vial filling critical in pharmaceuticals?

Aseptic vial filling ensures that both the container and product remain free from microbial contamination. It employs cleanroom environments (ISO class 5/7), sterilized component pathways (CIP/SIP), and barrier systems like isolators or RABS. This process protects patient safety and achieves regulatory compliance.

3. What are the main steps in a vial filling line?

A typical sequence includes:

1.Vial feeding onto conveyors

2.Washing and depyrogenation

3.Sterile filling

4.Stoppering (rubber stoppers inserted)

5.Optional freeze‑drying for powders

6.Capping (aluminum/plastic caps)

7.Vision inspection and labeling

4. What pump technologies do vial filling machines use?

Common pump types include:

● Rotary piston pumps – precise and versatile

● Peristaltic pumps – product-contact isolation

● Rolling diaphragm pumps – sterile fluid paths

● Time-pressure fillers – simple, effective for clear solutions

5. What are the different types of vial filling machines?

They include:

● Desktop/benchtop machines for R&D and pilot runs

● Semi-automatic machines with manual loading

● Fully automatic integrated lines with unsramblers

● Rotary vs. linear configurations depending on throughput needs

● Lyophilization-ready systems for freeze-dried products

6. How accurate are vial filling machines?

High-end systems using servo-driven pumps can achieve fill accuracy better than ±1%, monitored by precision sensors or weight-based in-process control. This minimizes overfilling or underfilling and meets strict pharmaceutical standards.

7. What industries use vial filling equipment?

Applications include:

● Pharmaceutical & biotech: vaccines, injectables, biologics

● Research labs: reagents, diagnostic solutions

● Veterinary medicine: vaccines and injectables

● Cosmetics: serums and liquid skincare

● Specialty chemicals and nutraceuticals requiring precise dosing

8. What is the difference between liquid and powder vial filling lines?

● Liquid vial filling lines use pumps (e.g. peristaltic, piston) to dispense solutions.

● Powder vial filling lines employ auger or vacuum systems to handle dry formulations, often for lyophilized products.

9. How is sterility maintained during filling?

Sterility is ensured through:

● Cleanroom or isolator environments

● CIP/SIP of fluid pathways

● Barrier systems like RABS

● Sterilized vials and stoppers supplied through tunnels or trays

● Validated, controlled operations following GMP protocols

10. What should manufacturers consider when choosing a vial filling machine?

Key considerations include:

● Product type (liquid vs. powder)

● Desired throughput and vial size flexibility

● Accuracy requirements

● Level of automation needed

● Compliance with GMP and cleanroom standards

● Integration with upstream (washers, sterilizers) and downstream (inspectors, labelers) systems

| References: | |

| 1. | Elegantly Simple: Aseptic Technologies’ process revolutionizes closed vial filling ——Retrieved from:PharmaceuticalProcessingWorld |

| 2. | “Aseptic vial filling” (PubMed Abstract) ——Retrieved from:National Library of Medicine |

| 3. | “Aseptic Vial Filling for Sterile Injectables: Ensuring Compliance in Drug Manufacturing” (GBI Biomanufacturing, 2024) ——Retrieved from:gbibio.com |

Comments