Proper tea packaging is critical for preserving aroma, flavor, and quality. A good tea package shields leaves from moisture, air and light, preventing spoilage and ensuring a long shelf life. At the same time, the material must be food-safe, printable for branding, and convenient for consumers. In practice, tea makers use a variety of materials – from traditional foil and paper to modern biodegradable films – each with unique advantages. This guide explores 12 key tea packaging materials used today, explaining their properties, pros/cons, and typical uses. We also touch on how packaging machinery handles these materials for efficient tea packing.

To begin, any tea package must act as a barrier. The ideal material blocks moisture, oxygen, and light to keep tea fresh. It should also preserve the tea’s aroma and flavor without imparting off-tastes. In addition, modern consumers care about sustainability, so recyclability or compostability is increasingly important. When selecting a packaging material, manufacturers weigh these factors – barrier performance, food safety, convenience (resealability), printability, and environmental impact – to suit the tea type and brand. Below we list the most common materials and how they are used in tea packaging, along with cited evidence and practical notes.

- Barrier Protection: Any material must protect leaves from moisture, oxygen, and UV light. These elements degrade tea quality over time.

- Aroma Preservation: Packaging should be non-reactive and prevent loss of volatile oils. For example, aluminum foil is prized because it “does not absorb aromas, colors, or flavors”.

- Safety & Regulations: All packaging must be food-safe. Materials like tinplate are non-toxic by design, whereas plastics are regulated for food contact.

- Convenience: Features like resealable pouches or easy-open lids improve consumer experience. For example, paper or laminate pouches can include zippers so they can be resealed after opening.

- Environmental Impact: Sustainable materials (recyclable paper, biodegradable PLA, etc.) are favored as eco-awareness grows. (The EU, for instance, aims for all packaging to be recyclable by 2030.)

With these criteria in mind, the following sections detail the top 12 tea packaging materials:

1. Aluminum Foil (including Foil-Lined Pouches)

Aluminum foil is a classic packaging material for tea. Aluminum offers an excellent barrier: it blocks moisture, oxygen, and light almost completely. Thin foil sheets or foil-laminated films are commonly used for tea sachets, inner bags, or pouch linings. For example, foil bags (often multi-layer laminates with aluminum at the core) are popular because they can be heat-sealed and keep tea dry and aromatic.

- Advantages: Superior protection – aluminum has “good barrier properties against oxygen, moisture, and light”, keeping tea fresh. It is lightweight, strong, and inert (it doesn’t impart flavors). Flexible foil pouches also can be vacuum- or nitrogen-flushed before sealing for long shelf life.

- Disadvantages: Not biodegradable and recycling can be challenging once mixed with plastics. Pure aluminum (cans/tins) is recyclable, but thin laminated foil usually isn’t. Aluminum is also a good heat conductor, so foil packages often include a plastic or paper layer to avoid direct contact with tea. Additionally, aluminum is more expensive than simple films.

- Typical Uses: Foil pouches (sometimes called foil laminate pouches) are widely used for loose-leaf teas and single-serve tea sachets. High-end or export teas often use foil inner liners or individually-wrapped foil sachets to ensure freshness.

2. Tinplate (Metal Cans and Tins)

Tinplate (a steel sheet coated with tin) is often used for premium tea containers. Examples include decorative tea caddies and cylindrical tins. Tinplate cans are non-toxic and highly durable, providing an excellent barrier to air and moisture. Because they are rigid, they also protect the tea from physical damage.

- Advantages: Highly protective: Tinplate blocks moisture and oxygen very well, similar to aluminum foil. It is safe (non-toxic) and fully recyclable. Cans can be printed or embossed for attractive branding. Resealable lids add convenience for reuse.

- Disadvantages: Heavier and pricier than flexible packaging. Larger metal tins take up more space and cost more to ship. If not lined properly, metal can react with tea, but quality cans have internal coatings to prevent this.

- Typical Uses: Metal tins are common for gift-pack teas or specialty blends. They often come in bright colors or with intricate designs. After opening, tins are reused by consumers as storage containers.

3. Plastic Films (PE, PP, PET, etc.)

Polymeric plastic films are ubiquitous in tea packaging due to their versatility and low cost. Common plastics include polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET). These materials can be transparent or printed, forming pouches, liners, or wrappers.

- Advantages: Durable and Moisture-Proof: Plastics are naturally water-resistant and durable. For instance, PET or PP film pouches protect against dampness and are tear-resistant. They also allow tight seals via heat sealing or adhesives. Clear plastics let consumers see the tea leaves. Plastics are lightweight, keeping shipping costs down, and they are easy to process on high-speed packaging lines.

- Disadvantages: Environmental Impact: Most conventional plastics are not biodegradable and can persist for centuries. As \[19] notes, plastic “is not biodegradable and can take centuries to degrade”, contributing to pollution if not recycled. Plastic also has moderate oxygen permeability, so additives or coatings (like EVOH or metallization) are sometimes needed to improve shelf life.

- Typical Uses: Resealable poly bags (LDPE with zipper) are common for loose tea. Plastic liners are used inside paper cartons to keep tea fresh. Shrink sleeves or wrap-around labels on tea boxes are also plastic-based. Many stand-up pouches for tea blends are made entirely of laminated plastic films.

4. Paper and Paperboard

Paper-based materials are used widely in tea packaging for their eco-friendliness and printability. This category includes kraft paper bags, paperboard cartons, and specialty filter papers.

- Advantages: Eco-friendly and Brandable: 100% recycled paper is biodegradable and renewable. Paperboard cartons and folding boxes are easy to print on, offering vibrant branding and designs. Paper (when properly treated) can still protect tea by combining with other layers. For example, many tea companies use kraft paper pouches with an inner foil or plastic lining.

- Disadvantages: Lower Barrier: Plain paper alone is not moisture-tight. It often needs a barrier layer (foil lining or plastic lamination) to truly keep tea dry. Paper pouches also require careful sealing (e.g. heat-sealable coatings) and are generally bulkier than flexible film packages.

- Typical Uses: Cardboard tea boxes (paperboard) are very common for bagged teas or sampler packs. Individually wrapped tea bags may come in paper envelopes (often foil-lined). Kraft stand-up paper pouches with zip locks are used for loose teas – these pouches look rustic and eco-friendly, often with a clear window or full graphic prints.

5. Composite/Multi-Layer Laminates

Modern tea packaging frequently uses composite laminates – films made by bonding multiple layers of different materials. A typical laminate might include a layer of PET or polypropylene (for strength and printability), an aluminum foil or metallized film (for barrier), and a polyethylene layer (for sealing). These multi-layer pouches combine the best features of each material.

- Advantages: High Barrier and Flexibility: Laminates can be engineered for maximum shelf-life. For example, a 3-layer laminate (PET/Al/PE) provides excellent moisture and oxygen resistance, much like solid foil. At the same time, the outer printable layer and the inner sealant layer make it easy to label and seal. They are lighter than cans and can be formed into custom shapes (pillow packs, doypacks, stick packs, etc.).

- Disadvantages: Recycling Challenges: Because laminates mix plastics and metal, they are usually not recyclable in standard streams. This raises environmental concerns unless compostable laminates are used (see next section). They also require specialized machinery (like laminators or extrusion coaters) to manufacture the film.

- Typical Uses: Almost all stand-up pouches, doypacks, and stick packs for tea are made of such laminates. For instance, a corn tea with added flavors might be sold in a resealable laminated pouch. [Pouch.me](#) explains that their flexible laminate bags (polymer/paper/metalized layers) are “an excellent choice for tea packaging, preserving the tea’s freshness and flavor most effectively”.

6. Polylactic Acid (PLA) and Other Biodegradable Polymers

With eco-trends on the rise, biodegradable plastics are gaining traction. Polylactic acid (PLA), made from fermented plant starch (e.g. corn or sugarcane), is a prime example. PLA film can be used alone or as part of a composite.

- Advantages: Compostable and Renewable: PLA packaging will break down under industrial composting conditions, reducing landfill waste. It still provides a good moisture barrier and can be heat-sealed. Using PLA aligns with sustainability goals: for example, the U.S. EPA and EU are encouraging biodegradable packaging to cut greenhouse emissions. Some companies now offer PLA-zippered pouches and tea bags to meet eco-conscious demand.

- Disadvantages: Performance and Cost: PLA is generally more expensive than conventional plastic. It also requires specific conditions (high heat composters) to degrade fully; otherwise it may persist. Its barrier properties against oxygen are lower than aluminum, so PLA is often used in combination with other layers (e.g. PLA + paper or PLA + metallized films).

- Typical Uses: Biodegradable tea bags and sachets are often made from PLA mesh or non-woven fiber. Some brands use PLA-lined paper pouches for loose tea. The goal is to achieve compostability: for instance, all components of a tea bag (PLAzipped pouch + PLA string + compostable paper tag) can theoretically decompose after use.

7. Filter Paper and Fiber Composites (Tea Bag Materials)

Although not “packaging” in the shipping sense, tea bag materials deserve mention since they are the primary material in which tea is sold. Tea filter bags are typically made from porous paper or fiber composites:

- Filter Paper: Specially formulated filter paper (often bleached or unbleached abaca hemp/pulp) is widely used. It allows water to pass but retains leaves. Filter paper is safe and natural, but it tears if overloaded with heavy leaf blends. It provides good water flow and does not affect flavor.

- Synthetic/Nylon Mesh: Some pyramid tea bags use nylon (polyamide) or PET “silken” meshes. Nylon offers excellent strength and heat-sealability – it won’t tear and has good barrier until used in brew (then it’s fine). However, nylon is not biodegradable and some consumers prefer to avoid plastics in their tea. Nylon tea bags are durable and can create interesting bag shapes.

- Non-Woven (PLA or Wood Pulp): Newer tea bags use non-woven fabrics of PLA fiber or wood pulp. These look like cloth and are strong when wet, but will eventually compost. For example, the plant-fiber pyramid sachets often use a filter fiber composite of PLA and paper. They perform well for single-cup brewing and appeal to green-minded customers.

- Typical Uses: Filter paper is dominant for standard teabags (flat or envelope style). Nylon/PET is used for pyramid sachets (especially herbal teas). Cotton/muslin bags (resealable cloth sacks) are used for loose tea or reusable infusers. In terms of secondary packaging, dry teabags are often put in paper envelopes, cartons, or foil wrappers.

8. Silk and Cotton (Cloth Bags and Muslin)

Some specialty teas are sold in cloth bags. Unbleached cotton or muslin pouches (sometimes called loose tea infuser bags) offer a rustic, reusable option.

- Advantages: Reusability and Natural Appeal: Cloth bags can be washed and reused, generating less waste. Cotton is breathable and allows good infusion. It is natural and biodegradable if untreated. Silk (though often actually PET fiber) has been used for a luxurious single-use pyramid shape, prized for its “luxe appeal”.

- Disadvantages: Not Airtight: Cloth does not protect against moisture or oxygen for long periods. Hence, tea in cloth bags is usually sold inside a secondary package (like a box or resealable pouch). Cloth is also costlier. True silk is expensive and non-biodegradable (often substituted with nylon/PET).

- Typical Uses: Reusable muslin tea bags are sold empty or pre-filled for consumers who brew loose tea at home. Cloth or silk pyramids (often nylon-based) appear in premium brands (e.g. some herbal teas in pyramid sachets). These items are niche rather than main packaging.

9. Wood and Bamboo (Rigid Cases)

While less common, wood and bamboo can be used for high-end tea packaging, especially for gift sets. These are rigid, decorative boxes made of sustainable materials.

- Advantages: Premium Look: Wooden boxes or bamboo tins have a luxury feel and natural branding. They can be reused as storage. Wood offers a decent moisture barrier if sealed.

- Disadvantages: Cost and Weight: Wood is heavy and expensive to produce. These are not practical for large-scale distribution, and usually reserved for special editions. Wood is also bulky compared to foil or paper.

- Typical Uses: Limited edition teas (e.g. puerh brick in a wooden case) or collectible tins. Sometimes inner tea is wrapped in foil before being placed in a wooden box.

(No specific citation; based on common practice.)

10. Glass

Glass jars are another upscale packaging choice, though rare for loose tea. Glass is inert (won’t leach) and transparent.

- Advantages: Inert and Airtight: Glass keeps tea dry and visible, preserving aroma. It looks elegant and can be reused. Glass does not alter flavor.

- Disadvantages: Fragility and Weight: Glass can break easily and is heavy/costly to ship. It also needs airtight lids to be effective. These issues limit its use.

- Typical Uses: Specialty tea shops sometimes sell small glass jars of loose leaf tea. More often, glass is used for tea blends in tea bags (e.g. tea in tea-bag boxes inside a gift jar).

(No specific citation; general industry knowledge.)

11. Stand-Up Pouches (Flexible Laminated Pouches)

Although not a material per se (they are made of film/laminate), stand-up pouches deserve mention because they are ubiquitous. These are usually multi-layer laminated plastic/foil (discussed above) or kraft paper + foil. Their key feature is a zipper or seal that makes them resealable.

- Advantages: Convenience: Stand-up pouches stand upright on shelves and often include a zipper. As \[28] notes, paper or laminated pouches can be “resealed” for on-the-go use. They combine barrier layers (e.g. foil or plastic) with printable surfaces.

- Disadvantages: Composite Complexity: As noted above, they are complex laminates and hard to recycle.

- Typical Uses: Loose teas (like herbal blends or matcha) are frequently sold in zippered pouch bags. These pouches are usually made of a foil-lined laminate to keep the product fresh after opening.

12. Tea Bag Sachets and Single-Serve Packets

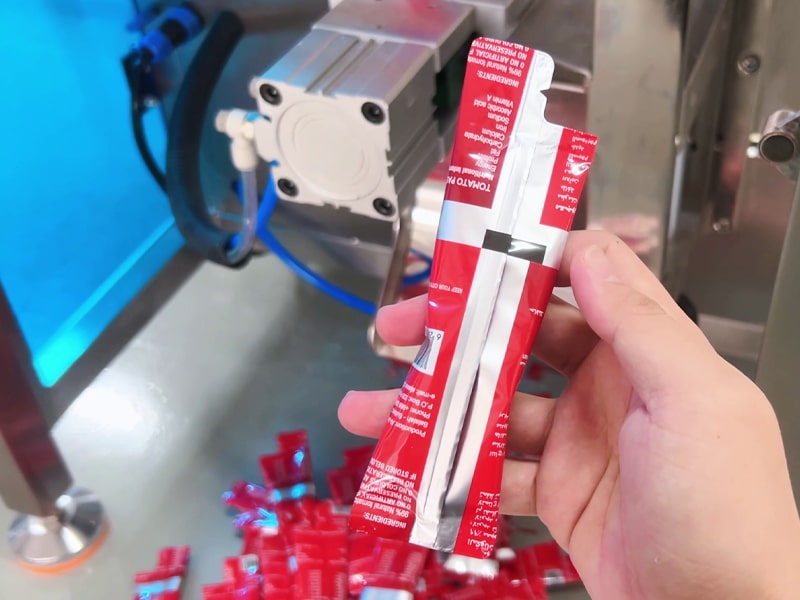

Finally, single-serve tea sachets (stick packs, pyramid bags, etc.) use specialized materials and packaging formats. The primary material is the tea bag (paper/PLA/nylon, as above), but the secondary packaging might be a foil envelope or flexible tube.

- Materials: Often each tea bag is wrapped in an envelope made of foil-lined paper or plastic film to insulate it. For example, a Lipton tea bag often comes in a paper envelope with an aluminum inner layer. This outer wrapper uses paper for print and foil/plastic for barrier.

- Purpose: These materials ensure that each tea bag stays dry, and they allow printing of labels and instructions. They are handled by specialized tea bag packing machines that weigh tea, fold the bag, attach tags, and insert it into an envelope.

- Typical Uses: Countless varieties of branded tea bags use these sachet materials. The materials chosen (paper, PLA, plastic) depend on cost and brand values (e.g. some brands now offer organic, unbleached filter paper bags in compostable wrappers).

Packaging Machinery and Material Processing

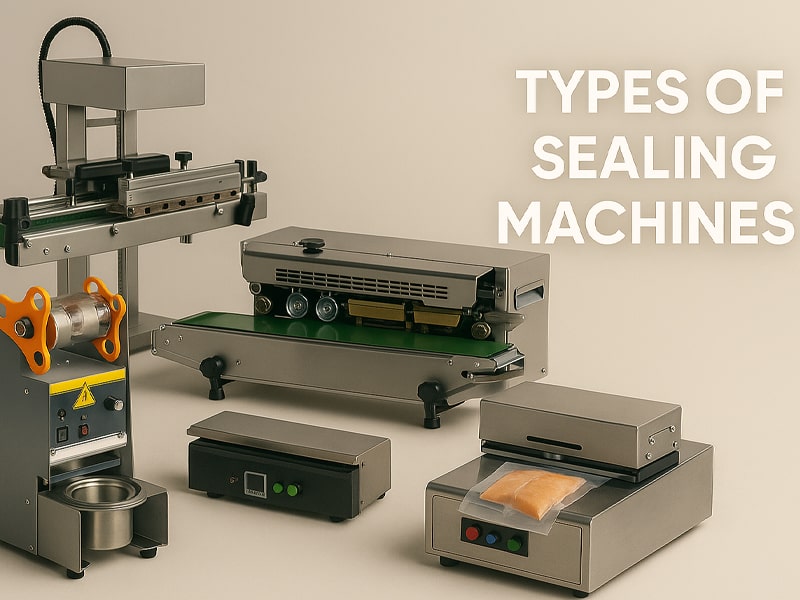

All the materials above are transformed into final packages using specialized packaging machines. For example, vertical form-fill-seal (VFFS) machines convert rollstock film or laminates into pouches by forming a tube, filling it with measured tea, and heat-sealing it. Tea bag packaging lines use machines that automatically fill filter bags, attach strings/tags, and wrap them in envelopes. Equipment exists for every packaging style: carton erecting machines for boxes, can seamers for tins, pouch filling machines, etc. Using automated machinery ensures consistent seals and hygienic handling of tea.

Manufacturers must match material to machine: e.g. a heat-sealer requires thermoplastic film (like PE layer) in the laminate. Machines also set parameters (temperature, pressure) according to material properties. In short, tea packaging machinery enables high-speed, precise use of these materials to produce consumer-ready tea products.

Conclusion

In summary, a tea producer today has many packaging material options. Aluminum foil and foil laminates offer the best protection against spoilage. Tinplate cans add a premium image and strong durability. Plastic films and paper-based packs provide cost-effective, printable solutions. Laminated multi-layer films blend these advantages into flexible pouches (widely used for loose tea). Biodegradable polymers like PLA and plant fiber are becoming essential for eco-friendly brands. Meanwhile, the material of the actual tea bag (filter paper, nylon, etc.) must allow brewing while retaining leaves. Each material balances barrier performance, cost, and sustainability differently.

Choosing the right tea packaging material ensures that customers receive fresh, flavorful tea. As one expert source puts it, the chosen material “will protect your tea leaves from moisture, oxygen, and light… keeping your tea fresh and flavorful”. By considering factors like shelf-life needs, environmental goals, and brand image, tea businesses can select the ideal packaging and utilize modern machinery to pack their tea professionally.

Comments