In the vast and intricate landscape of modern manufacturing, the efficient and precise packaging of liquid products is paramount. From pharmaceuticals and nutraceuticals to food and beverages, the need for accurate and hygienic filling processes is non-negotiable. Among the myriad of liquids requiring specialized handling, viscous products like syrups present a unique set of challenges. Their inherent stickiness and resistance to flow demand filling solutions specifically engineered for their properties. This is where the Syrup Filling Machine plays a pivotal role, serving as an indispensable tool for manufacturers seeking both high throughput and unwavering accuracy.

While the term “syrup” often evokes images of sweet concoctions for culinary delight or medicinal relief, the principles and technology behind Syrup Filling Machines extend far beyond these applications. They represent a specialized facet of the broader field of liquid filling machinery, a domain critical to global production. This comprehensive guide will delve into the intricacies of Syrup Filling Machines, exploring their operational principles, diverse types, key components, applications, and the critical factors to consider when selecting the optimal solution for your production needs. We will examine the scientific and technical aspects that underpin their functionality, highlighting how these machines embody precision engineering and process optimization. By understanding the “why” and “how” behind these vital pieces of equipment, manufacturers can make informed decisions that significantly impact their efficiency, product quality, and ultimately, their bottom line.

Understanding the Challenges of Syrup Filling

Before delving into the specifics of Syrup Filling Machines, it’s essential to understand why syrups require specialized handling. Unlike low-viscosity liquids like water, syrups possess a higher viscosity, meaning they resist flow more readily. This characteristic poses several challenges for traditional liquid filling methods:

● Slower Flow Rates: Viscous liquids flow more slowly, significantly impacting filling speed and overall production throughput.

● Air Entrapment: As viscous liquids flow, they are more prone to trapping air bubbles, which can lead to inaccurate fill volumes and an undesirable product appearance.

● Product Stringing and Dripping: The stickiness of syrups can cause the liquid to string or drip after the filling nozzle is retracted, leading to product waste and contamination of the filling environment and containers.

● Cleaning Difficulty: The sticky nature of syrups makes cleaning and sanitizing filling equipment more challenging and time-consuming, which is crucial for maintaining hygiene standards, especially in pharmaceutical and food applications.

● Filling Accuracy: Achieving consistent and accurate fill volumes with viscous liquids requires precise control over the filling process to account for their flow behavior.

These challenges necessitate filling technologies specifically designed to overcome them, ensuring efficient, clean, and accurate syrup packaging.

The Core Principles of Syrup Filling Machines

At their heart, Syrup Filling Machines are engineered to handle viscous liquids with precision and efficiency. While various technologies exist, the underlying principles often involve:

● Positive Displacement: Many Syrup Filling Machines utilize positive displacement principles. This means that a fixed volume of liquid is precisely measured and dispensed into each container, independent of variations in liquid viscosity or pressure. Common positive displacement mechanisms include:

● Piston Fillers: A piston moves within a cylinder, drawing a measured volume of syrup into the cylinder on the suction stroke and expelling it into the container on the discharge stroke. This method is highly accurate and suitable for a wide range of viscosities.

● Peristaltic Pumps: These pumps use rotating rollers to compress a flexible tube, creating a positive displacement flow of liquid through the tube. They are particularly useful for sterile or highly sensitive products as the liquid only contacts the interior of the tube, minimizing contact with machine components.

● Rotary Lobe Pumps: These pumps use rotating lobes to trap and move a fixed volume of liquid through the pump chamber. They are suitable for viscous liquids and can handle products with suspended solids.

● Gravity Filling (with modifications): While less common for highly viscous syrups, modified gravity fillers can sometimes be used for lower-viscosity syrups. These systems rely on the weight of the liquid to fill containers, but require larger nozzles and careful control to manage the slower flow and prevent dripping. Overflow gravity fillers can also be used to ensure consistent fill levels, with excess syrup returned to a reservoir.

● Vacuum Filling: While primarily used for thin liquids, vacuum filling can be adapted for some less viscous syrups by creating a vacuum in the container to draw the liquid in. However, it is generally less effective for very high-viscosity products.

● Pressure Filling: Applying pressure to the syrup reservoir can increase the flow rate and improve filling speed, especially for thicker syrups. This is often used in conjunction with positive displacement systems.

The choice of filling principle depends on the syrup’s viscosity, required filling speed, desired accuracy, and product characteristics (e.g., presence of particles, sterility requirements).

Exploring the Diversity: Types of Syrup Filling Machines

Syrup Filling Machines are available in a variety of configurations and levels of automation to meet the diverse needs of manufacturers. These broadly fall into:

● Manual Syrup Filling Machines: These are the simplest type, requiring an operator to manually place containers under the filling nozzle and initiate the filling process. They are suitable for small-scale production, laboratory use, or start-up businesses with limited budgets. While cost-effective, they offer lower throughput and are more susceptible to variations in fill volume due to manual operation.

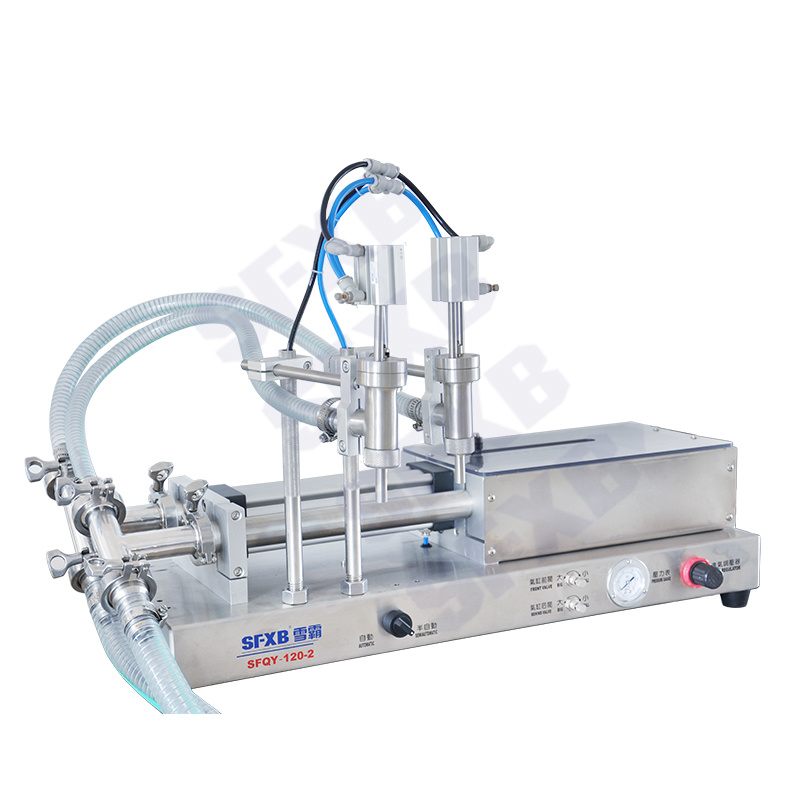

● Semi-Automatic Syrup Filling Machines: These machines automate the filling process while still requiring an operator to manually load and unload containers. They offer higher throughput than manual machines and improved filling accuracy. Common types include tabletop semi-automatic fillers and larger, floor-standing models. They are a good option for medium-scale production runs.

● Automatic Syrup Filling Machines: These machines are fully automated, handling container feeding, filling, and often capping or sealing without operator intervention. They are designed for high-volume production and offer the highest level of efficiency, speed, and filling accuracy. Automatic syrup fillers can be linear or rotary:

● Linear Automatic Fillers: Containers move along a conveyor belt and are filled sequentially at multiple filling stations. They are flexible and can handle a range of container sizes and shapes.

● Rotary Automatic Fillers: Containers are indexed around a rotating turret and filled at high speed. They are ideal for very high-volume production of a single or limited range of container types.

|

| Twelve-head high-speed linear double row bottle feeding/filling/rotary capping/labeling/bottle receiving production line |

The level of automation chosen depends on factors such as production volume, budget, labor availability, and desired efficiency.

Key Components and Features of Syrup Filling Machines

A Syrup Filling Machine is a complex system composed of several interconnected components working in harmony to achieve precise and efficient filling. Key components and features include:

● Filling Nozzles: These are critical for dispensing the syrup into containers. Specialized nozzles are designed to handle viscous liquids, minimizing dripping and stringing. Anti-drip nozzles, diving nozzles (which descend into the container during filling to reduce foaming), and cut-off nozzles are common features.

● Filling Pump or Mechanism: As discussed earlier, this is the heart of the machine, responsible for accurately measuring and dispensing the syrup. The type of pump (piston, peristaltic, lobe, etc.) is chosen based on the syrup’s characteristics.

● Container Handling System: This system is responsible for accurately positioning and holding containers under the filling nozzles. This can range from simple manual placement areas to sophisticated automated conveyor systems, indexing wheels, or star wheels.

● Syrup Reservoir/Tank: This holds the bulk syrup supply. It may include features like stirring mechanisms to maintain product consistency, heating elements to reduce viscosity, or cooling systems to maintain product stability.

● Control System (PLC): Modern Syrup Filling Machines are controlled by a Programmable Logic Controller (PLC), which manages all aspects of the filling process, including fill volume, speed, container indexing, and safety interlocks. This allows for precise control and easy adjustments.

● User Interface (HMI): A Human-Machine Interface (HMI), typically a touchscreen, allows operators to monitor and control the machine, set parameters, and access diagnostic information.

● Sanitation and Cleaning Features: Given the sticky nature of syrups and the importance of hygiene, especially in food and pharmaceutical applications, Syrup Filling Machines are designed for easy cleaning and sanitation. Features like quick-disconnect fittings, clean-in-place (CIP) systems, and sanitary materials are crucial.

● Safety Features: Safety is paramount in any manufacturing environment. Syrup Filling Machines incorporate safety features such as safety guards, emergency stop buttons, and interlocks to protect operators.

Understanding these components helps in appreciating the engineering and design considerations that go into building a reliable and efficient Syrup Filling Machine.

Applications Across Industries: Where Syrup Filling Machines Thrive

The versatility of Syrup Filling Machines makes them indispensable across a wide range of industries where viscous liquids are packaged. Some key applications include:

● Pharmaceutical Industry: Syrups are widely used in pharmaceuticals for oral medications (cough syrups, antibiotics, vitamins) and other liquid formulations. Syrup Filling Machines in this sector must meet stringent regulatory requirements for accuracy, sterility, and traceability.

● Food and Beverage Industry: From culinary syrups (pancake syrup, chocolate syrup, fruit syrups) and sauces to honey and viscous dressings, the food and beverage industry relies heavily on accurate and hygienic syrup filling.

● Nutraceuticals and Supplements: Liquid vitamins, dietary supplements, and other nutraceuticals often have a syrup-like consistency, requiring specialized filling solutions.

● Cosmetics and Personal Care: Viscous products like lotions, gels, and some liquid soaps are packaged using machines based on the principles of syrup filling.

● Chemical and Industrial Products: Certain chemical and industrial liquids with higher viscosity also benefit from the controlled and precise filling offered by these machines.

The specific requirements of each industry, such as hygiene standards, fill accuracy tolerances, and production volume, influence the type and features of the Syrup Filling Machine chosen.

Selecting the Right Syrup Filling Machine: A Critical Decision

Choosing the optimal Syrup Filling Machine for your needs is a critical decision that can significantly impact your production efficiency and product quality. Several factors should be carefully considered:

● Product Viscosity: The viscosity of your syrup is the most crucial factor. Machines designed for low-viscosity liquids will not perform effectively with thick syrups, and vice versa. Ensure the machine is specifically rated for the viscosity range of your product.

● Production Volume: The required production throughput will determine the level of automation needed. Small businesses may suffice with a manual or semi-automatic machine, while large-scale manufacturers require high-speed automatic systems.

● Container Type and Size: Consider the type of containers (bottles, jars, pouches, etc.) and their size range. The machine’s container handling system and nozzle configuration must be compatible.

● Required Filling Accuracy: The desired level of fill accuracy is critical, especially in pharmaceuticals where precise dosing is essential. Positive displacement fillers generally offer the highest accuracy.

● Budget: Syrup Filling Machines vary significantly in price depending on their level of automation, features, and capacity. Establish a realistic budget and explore options within that range.

● Hygiene and Cleaning Requirements: Especially for food and pharmaceutical applications, ease of cleaning and sanitation is paramount. Look for machines with sanitary designs, CIP capabilities, and materials that are easy to clean and resistant to product buildup.

● Ease of Operation and Maintenance: Consider the complexity of operating and maintaining the machine. A user-friendly interface and easily accessible components for maintenance can reduce downtime and training costs.

● Supplier Reputation and Support: Choose a reputable manufacturer like SFXB (https://www.xuebapack.com/) with a proven track record in building reliable filling machinery and offering excellent after-sales support, including installation, training, and spare parts.

● Flexibility and Future Needs: Consider if you anticipate needing to fill different syrup types or container sizes in the future. Choosing a machine with some degree of flexibility can be a wise investment.

By carefully evaluating these factors and consulting with experienced machine suppliers, manufacturers can make an informed decision that leads to a successful and efficient syrup packaging operation.

Beyond the Syrup: The Broader World of Liquid Filling Machines

While this guide has focused on Syrup Filling Machines, it’s important to recognize that they are part of a larger family of liquid filling equipment. Understanding the broader context of liquid filling technology can provide valuable insights. Liquid filling machines are classified based on various factors, including:

● Filling Principle: Gravity, pressure, vacuum, positive displacement (piston, gear, peristaltic), net weight, overflow, etc.

● Level of Automation: Manual, semi-automatic, automatic.

● Container Handling: Linear, rotary.

● Product Type: Thin liquids, viscous liquids, foaming liquids, products with particles, sterile liquids.

Each type of liquid filling machine is optimized for specific product characteristics and production requirements. For instance, gravity fillers are ideal for low-viscosity, non-foaming liquids, while net weight fillers are used when precise product weight is critical. Syrup Filling Machines, with their focus on handling viscosity, represent a specialized solution within this broader spectrum. Manufacturers who handle a variety of liquid products may require different types of filling machines or flexible systems that can be adapted for different applications.

Technological Advancements in Syrup Filling Machines

The field of liquid filling technology is constantly evolving, driven by the need for greater efficiency, accuracy, and flexibility. Recent advancements in Syrup Filling Machines include:

● Improved Dosing Accuracy: More sophisticated control systems and refined positive displacement mechanisms are leading to even higher levels of filling accuracy.

● Enhanced Cleaning Systems: Automated CIP systems and innovative nozzle designs are making cleaning faster, more effective, and less reliant on manual labor.

● Increased Automation and Integration: Syrup Filling Machines are increasingly integrated with other packaging equipment, such as capping machines, labeling machines, and cartoners, to create fully automated packaging lines.

● Remote Monitoring and Control: Cloud-based platforms and IIoT (Industrial Internet of Things) technologies allow manufacturers to remotely monitor machine performance, track production data, and even troubleshoot issues.

● Sustainable Design: Manufacturers are focusing on designing machines that are more energy-efficient, use less water for cleaning, and minimize product waste.

● Quick Changeover Features: Features that allow for faster and easier changeovers between different container sizes or syrup types are becoming increasingly important for manufacturers with diverse product portfolios.

These advancements are enabling manufacturers to achieve higher levels of productivity, reduce costs, and improve overall operational efficiency.

Conclusion: The Sweet Success of Optimized Syrup Packaging

In the competitive landscape of modern manufacturing, the ability to efficiently and accurately package viscous liquids like syrups is a significant advantage. Syrup Filling Machines, with their specialized engineering and diverse capabilities, are essential tools for achieving this. From understanding the unique challenges posed by syrup viscosity to exploring the different types of machines and their key components, this guide has provided a comprehensive overview of this vital technology.

Choosing the right Syrup Filling Machine is not just about purchasing a piece of equipment; it’s about investing in a solution that optimizes your production process, ensures product quality, and contributes to your business’s success. By carefully considering factors such as product viscosity, production volume, accuracy requirements, and hygiene standards, manufacturers can select a machine that meets their specific needs and delivers reliable performance.

As technology continues to advance, Syrup Filling Machines will become even more sophisticated, offering greater accuracy, speed, and integration capabilities. By staying abreast of these developments and partnering with experienced manufacturers like SFXB, businesses can ensure they are equipped with the best possible solutions for their syrup packaging needs, paving the way for sweet success in the market.

| References: | |

| 1. | Ludwigson, M. (2021). Positive Displacement Pump Selection. PDH Academy |

| 2. | EHEDG. (2018). Doc. 46: Aseptic and Hygienic Filling Machines – Planning, Installation, Qualification and Operation. Retrieved from:EHEDG Guideline |

| 3. | High-accuracy filling machine leverages latest technology Retrieved from:Packaging World |

| 4. | A New Automated and High Speed Machinery System for Filling High Viscous Liquids Retrieved from:ResearchGate |

Hey There. I found your blog using msn. This is a very well written article.

I’ll be sure to bookmark it and come back to read more of your useful information. Thanks for the post.

I’ll definitely return.