Screw capping machines are a cornerstone of modern packaging lines, automating the application of threaded caps onto bottles and jars. By precisely screwing lids onto containers, these machines streamline the sealing process, dramatically increasing speed and consistency. Industry data confirm that such automation can boost production throughput by up to 30%, since machines run continuously without human fatigue. At the same time, better torque control and repeatability lead to higher-quality seals – studies report spoilage rates can drop by around 5% when using machine-tightened caps. In short, automatic screw capping machines make packaging both faster and more reliable, helping manufacturers cut labor costs and reduce product waste.

Containers capped with this equipment stay fresher and safer. Screw capping machines tightly seal bottles with various closures (plastic, metal or composite caps) to prevent leaks, contamination, and tampering. They are widely used across industries – from food and beverage to cosmetics, pharmaceuticals and chemicals. For example, glass jars of sauce, plastic water bottles, and even chemical drums can be handled by the same capping technology (often with quick changeovers for different sizes). In fact, these machines are extremely versatile. Modern cappers can be set up to handle nearly any bottle material or shape – glass, PET, HDPE, PP and more – from tiny vials to large multi-liter containers. Their adaptability is a key reason they’re considered a must-have for high-volume production lines.

Key Components of a Screw Capping Machine

A screw capping machine is a complex assembly of mechanisms, each playing a critical role in the capping process. The major components include:

- Cap Feeder: A hopper or vibratory bowl that orients and supplies caps one by one. It sorts mixed caps and feeds them onto the line so each bottle receives a cap. Precise feeding keeps the line running smoothly.

- Conveyor Belt: Continuously moves filled bottles into position under the capping heads. It ensures a steady flow so the machine can work at high speed.

- Bottle Gripper/Star Wheel: (In some designs) Holds or indexes bottles during capping to prevent tipping or rotation. For example, star wheels may position bottles accurately as caps are applied.

- Capping Head (Chuck or Spindle): The mechanism that actually tightens the cap. In spindle cappers, rotating wheels (spindles) spin the cap onto the bottle threads. In chuck cappers, a descending head with a universal chuck grips the cap and twists it onto the bottle. Both types use torque control to achieve the correct tightness without over-screwing.

- Torque Control/Clutch System: A built-in torque clutch stops the tightening once the preset torque is reached. This prevents over-tightening which could damage the cap or container, or make it impossible to open. Modern machines often use a pneumatic or electronic clutch that can be adjusted for different caps and bottle materials. For example, servo-driven heads provide precise torque monitoring for consistency.

- Frame and Control Cabinet: The robust frame holds all parts in place. Inside, a PLC or microcontroller and servo drives (or pneumatic logic) control the timing, speed, and torque settings. A control panel lets operators set parameters like torque value, cap size, and conveyor speed.

- Sensors and Inspection: Many cappers include sensors (photo-eyes or torque sensors) to detect bottle presence, cap placement, and torque accuracy. After capping, the machine can reject improperly capped bottles. These quality checks ensure each seal meets standards before products move on.

Each component must be calibrated and synchronized. For instance, the speed of the cap feeder and conveyor is matched so that each bottle arrives exactly when a cap is delivered. The capping heads then apply the caps one by one with controlled force. Together, these parts turn what was once a slow manual task into a rapid, automated cycle.

The Capping Process: Step by Step

A screw capping machine operates through a series of coordinated steps. Here’s a typical sequence in an automatic capping line:

- Cap Feeding: Caps (mixed and loose) are poured into a vibratory feeder bowl, which orients them upside-down. The feeder delivers individual caps to a chute or track. As bottles move on the conveyor into position, a cap is sent ahead to meet each arriving bottle.

- Cap Placement: When a bottle reaches the capping station, the machine places a cap onto its neck. In some machines, a cap drop arm gently sets the cap on the container. In a fully automatic system, this is timed so each bottle meets its cap exactly. (In semi-automatic machines, an operator might place the cap by hand into position before it reaches the head.)

- Torque Application: As soon as the cap is seated, the capping head engages. It comes down (for a chuck capper) or spins around the bottle (for a spindle capper) and begins to tighten the cap. The head applies a twisting force (torque) to screw the cap on. This force is calibrated carefully: enough to seal the container securely, but not so much as to strip the threads or deform the parts. Sensors or clutches on the head stop the torque once the target value is reached.

- Release and Index: The capped container is released from the gripper or star wheel, and the conveyor moves it onward. Meanwhile, the next bottle has been moved into place. In a continuous-motion rotary capper, this happens seamlessly for every bottle. In an intermittent machine, the conveyor may index forward after each cycle.

- Inspection: After capping, the machine checks the result. This can be a manual check by workers or an automated system (like a cap-count sensor or laser measure) that verifies each cap is present and properly tightened. Only bottles that pass inspection proceed to labeling or packing.

Each of these steps typically happens in fractions of a second for an automatic machine. For example, high-speed rotary cappers (like the XBXG-6/8/10 heads automatic rotary capping machine) can handle up to 100–200 bottles per minute. In such machines, multiple capping heads work in parallel on different bottles in a rotating carousel, allowing continuous high output. Even mid-range machines may cap 100–300 bottles per minute easily. (Semi-automatic models cap slower – often 20–50 bottles/min, suitable for pilot runs or small batches.)

Torque Control: Ensuring the Perfect Seal

An essential aspect of screw capping is torque – the twisting force needed to seal the cap. Torque is measured as force times distance (commonly in Newton-meters, Nm). The required torque varies by cap and bottle: a thin PET water bottle might only need a few Newton-meters, while a heavy glass jar with a metal lid needs much more. In practice, most beverage bottles are in the 5–10 Nm range, but caps on large pickle jars can go beyond that.

Modern cappers allow precise torque adjustment. The machine’s clutch or servo head is set so that it stops applying force at exactly the set torque. This “governed” tightening means every cap is finished to spec – not too loose (which could leak) and not too tight (which could crack the container or make opening difficult). Some machines even measure the torque on each bottle, flagging any anomalies. The use of magnetic clutches and servo motors has made this very accurate. For instance, SFXB’s high-speed systems use a frictionless magnetic clutch to achieve reliable, repeatable torque at high speeds.

Controlling torque carefully is critical. It ensures product safety (no leaking or spoilage) and customer experience (caps open easily). It’s also key for tamper-evidence: a properly torqued cap stays on until deliberately opened. Thus, high-end screw cappers often include real-time torque monitoring, sometimes called torque control heads or torque monitoring systems, to maintain consistency across millions of containers.

Adjustments and Cap Size Flexibility

Screw capping machines are designed for flexibility. They can adapt to a wide range of cap diameters and shapes with simple adjustments. For example, many cappers use interchangeable chuck heads or gaskets that can be swapped to fit caps from small (20–30 mm) up to large (80–100 mm) diameters. Some machines feature a universal or self-centering chuck that automatically grips any cap within a broad range (e.g. 28–70 mm) without manual changeover.

This adaptability means one machine can handle different product lines. As shown, a jar-filling factory might package various products – all with different cap sizes. The same screw capper can be tweaked (by changing chuck inserts or readjusting guides) to run jars one day and bottles the next, all without major downtime. The key is that the capping head’s position and clutch settings are easily set by controls or handwheels. Once adjusted, the machine automatically applies the correct torque to each new cap size.

Manufacturers often specify a range of cap diameters their machines can handle. For example, a versatile chuck capper might cover 28–82 mm with change parts, while a spindle capper might accommodate even larger lids. The design of conveyors and bottle guides also allow quick changeover: slide-in guides, adjustable rails, and smart sensors help the next production run start fast. In summary, modern screw cappers stay highly versatile, ready to switch between products without sacrificing seal quality.

Types of Screw Capping Machines

Screw capping machines come in several forms to suit different production needs:

- Manual Cappers: Hand-operated tools or bench-top machines for very low volumes. An operator holds or places each cap and uses a lever or wrench to tighten it. These are simple and low-cost but very slow (a few bottles per minute), typically used in lab settings or small startups.

- Semi-Automatic Capping Machines: The operator usually places bottles (and sometimes caps) in position, and the machine drives the capping head. For example, the worker might align a bottle under a descending chuck and pull a trigger to tighten the cap to preset torque. These machines can cap ~20–50 bottles per minute, faster than manual methods, and often include adjustable torque settings. They offer a good balance for medium production without full automation.

- Automatic (Fully Automatic) Capping Machines: These are integrated into packaging lines and need minimal human intervention. A fully automatic screw capper uses a feeder to place caps and moves bottles mechanically under spinning heads. It can seal hundreds to thousands of bottles per minute. As one source notes, automatic machines can feed, orient, and apply caps to containers at high speeds, cutting labor costs and maximizing output. Large rotary cappers can easily reach 600–1200 bottles per minute by using multiple capping stations in parallel.

In addition to automation levels, screw cappers are classified by their capping method (spindle vs. chuck) as noted above. Spindle cappers use rotating wheels to tighten caps as bottles pass by, suitable for wide, continuous lines. Chuck cappers lower a threaded head onto each bottle, ideal for precise control, common in pharmaceutical or chemical packaging where accuracy is critical. Both styles can be found as single-head (for very slow lines), multi-head rotary (for high throughput), or inline continuous-motion machines.

Integrating into Production and Productivity

Integrating a screw capping machine into a filling line requires matching its speed and format to other equipment. For best results, ensure the capping rate matches the filler output. For example, if a bottling line fills 120 bottles per minute, the capping machine should be set (and maintained) to cap at the same pace without creating a backlog. Modern machines allow syncing conveyors, and many have buffers or accumulating tables to handle slight mismatches.

Choosing an automatic screw capping machine offers clear productivity advantages. It reduces the need for manual labor (for cap application), freeing workers for other tasks and improving workplace ergonomics. Studies show that switching from a semi-automatic to automatic system can increase output by up to 50%. It also improves consistency: every bottle is capped with the same torque and position, minimizing rejects. Furthermore, automatic machines often incorporate features like reject stations and sorting, which further raise yield.

An example of high productivity is the SFXB rotary capper: it can handle all sorts of screw caps across up to 100-200 bottles per minute. Its magnetic-clutch heads provide rapid, reliable torque application even at top speed. For most medium-scale lines, a top-end continuous-motion capper achieves 200–600 bottles/min, as noted in industry reports. In all cases, using an automatic screw capper aligns with lean manufacturing goals by boosting throughput and cutting waste.

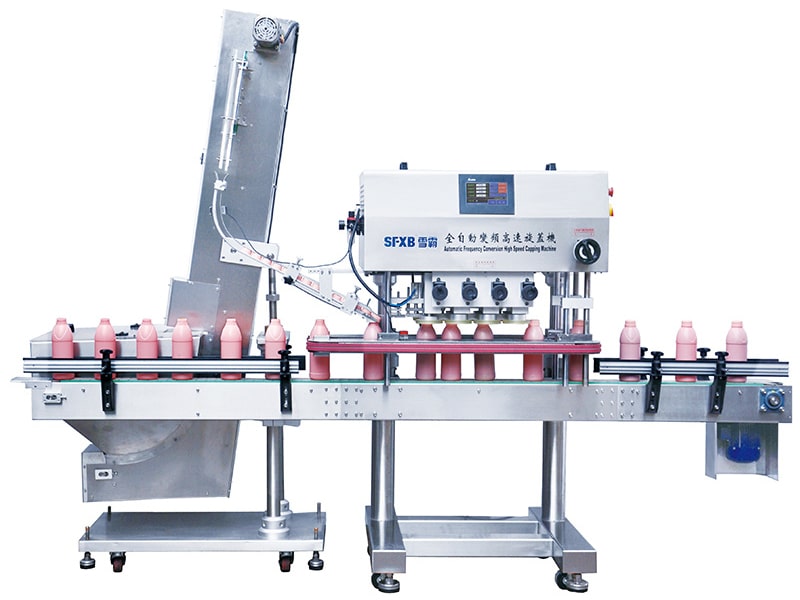

Figure: Fully automatic frequency conversion high speed capping machine

Above, a modern screw capping system is shown handling plastic chemical containers. Such machines can be configured with specific cap feeders and chucks to handle different industries (chemical, personal care, food, etc.). As SFXB experts note, these machines provide consistent seals that preserve product integrity and meet safety standards. Whether in a cosmetics plant or a juice bottling facility, integrating a quality capping machine ensures operational efficiency and product quality.

Maintenance and Reliability

Like any precision equipment, screw capping machines require regular maintenance to remain reliable long-term. Here are best practices to keep them running smoothly:

- Lubrication: Keep gears, slides, and bearings well-oiled according to the manufacturer’s schedule. Proper lubrication reduces wear and noise.

- Torque Check: Periodically verify that the machine is applying the correct torque. Use a calibrated torque tester on sample caps to ensure settings haven’t drifted.

- Cleaning: Clear away dust, debris, and any spilled product from the machinery. A clean capper avoids jams and hygiene issues. Use recommended cleaners on conveyor belts and cap feeders.

- Inspect Wear Parts: Examine gripping jaws, chuck inserts, belts, and sensors for signs of wear. Replace any parts that look worn or cracked before they fail.

- Sensor Alignment: Ensure photo-eyes or other detectors are properly aimed and dust-free, so every bottle and cap is detected reliably.

- Operator Training: Make sure staff are trained to notice problems like inconsistent cap placement or strange noises. Early detection by an informed operator prevents bigger shutdowns.

Following these steps (and the equipment manual) will keep the machine capping accurately. Many modern machines also come with simple touchscreen diagnostics or alert systems to schedule maintenance proactively. Good maintenance not only extends machine life but also protects product quality — a misaligned or dirty machine can cause cap leaks or contamination if left unchecked.

FAQ Highlights

1. What types of closures can a screw capping machine handle?

Screw capping machines—whether spindle or chuck types—are designed for continuous-thread, screw-on closures commonly used in bottled water, beverages, cleaning products, pharmaceuticals, cosmetics, and more.

2. Will the machine handle different bottle shapes and sizes?

Yes. With simple adjustments like double gripper belts or change parts, most machines can accommodate various bottle widths and heights. Some machines even support mixed bottle formats with minimal modification.

3. How fast can an automatic screw capping machine cap bottles?

Speeds vary: inline automatic machines can exceed 100 bottles per minute, while semi-automatic speeds depend on the operator.

4. How much floor space is required for the machine?.

Semi-automatic or tabletop units require minimal space, whereas fully automatic machines include conveyors and cap feeders, demanding more production line real estate.

5. Is the machine easy to operate and adjust?

Yes. Most machines feature toolless adjustments—hand knobs, cranks—and simple controls. Automatic models often include touchscreen panels and are designed for easy changeover and minimal operator training.

6. Does it deliver consistent torque and seal quality?

Absolutely. Machines employ torque-controlled heads or clutches to apply precise torque, preventing over‑ or under‑tightening for reliable seals and tamper evidence.

7. What speed, flexibility, and efficiency benefits can screw capping machines offer?

Automatic machines offer increased speed, consistency, and reliability over manual methods. They enhance throughput, reduce labor needs, and improve product integrity—yielding better productivity and ROI.

8. How do I choose the right screw capping machine model?

Consider torque control needs (e.g., CG series with preset torque for pharma), cap size range (CC vs. CS series for wider cap size coverage), and your production scale when selecting a suitable model.

9. Can screw capping machines be integrated into existing production lines?

Yes. Automatic models can be seamlessly integrated with infeed/outfeed conveyors and existing fillers, ensuring synchronized operation and line efficiency.

10. What maintenance is needed to keep the capping machine reliable?

Regular maintenance is recommended, including cleaning, lubrication, torque calibration, wear‑part inspection, and operator training—this helps maximize uptime and seal quality.

11.Can a screw capping machine handle different bottle types?

Yes – virtually any shape or material can be capped. Cylindrical bottles are easiest, but rectangular or odd shapes can be accommodated with minor adjustments to guides and chucks. These machines are used for tiny vials up to multi-liter containers with changeover parts.

12.What cap materials work?

Both plastic (e.g. polypropylene, polyethylene, PET) and metal caps (aluminum) are commonly used. The machine’s heads can grip either type; you simply choose the cap type based on product needs (plastic for food products, metal for beverages or chemicals, etc.).

Conclusion

In summary, a screw capping machine uses precise mechanical and control engineering to automatically apply and tighten caps on containers. It starts with a cap feeder that delivers caps, then a conveyance and head assembly that places and twists the caps at controlled torque, and finishes with quality checks on the sealed products. This automation greatly outpaces manual capping and enhances seal consistency across thousands of bottles.

For any manufacturer looking to boost packaging output and reliability, an automatic screw capper is an invaluable asset. By understanding how the capping process works, industries can better select and configure machines. Leading manufacturers like SFXB offer advanced automatic screw capping machines with features such as servo-controlled torque heads, easy cap changeovers, and robust construction to meet diverse needs. Investing in such a machine is often a logical step: it pays off through higher throughput, lower labor costs, and fewer packaging defects.

Comments