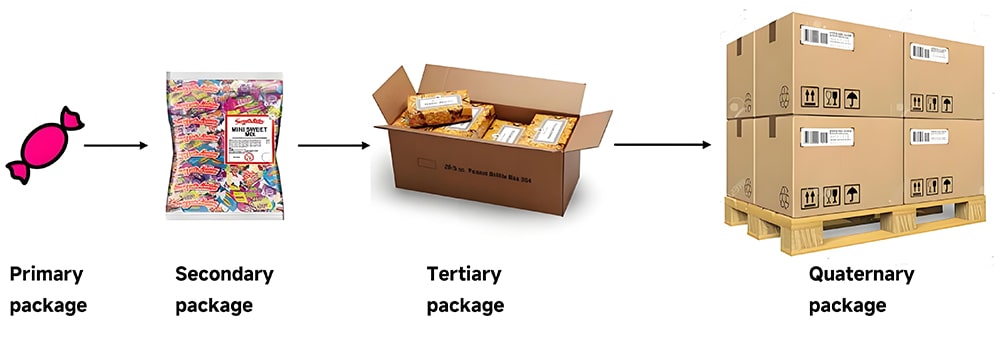

Packaging plays a critical role in the supply chain. It is “the only way to effectively transport a product from the manufacturer to the consumer,” acting as both a protective barrier and a marketing tool. In practice, manufacturers use multiple layers of packaging – primary, secondary, and tertiary – each with a distinct function. Primary packaging directly encloses and protects the product, while secondary packaging groups those primary units together (often for display or bulk handling). (For completeness, tertiary packaging – like pallets and crates – then protects large bundles of product during shipping.) Understanding the difference between primary packaging and secondary packaging is essential: the first touches the product and contains it, the second bundles and shields groups of products. In the sections below, we explain each layer in detail, give concrete examples, and highlight key considerations for each.

What Is Primary Packaging? Protecting the Product Directly

Primary packaging is any packaging material in direct contact with the product. This is the consumer’s immediate container or wrapper – the bottle, can, pouch or other package that actually holds the item. Its job is to preserve, contain and protect the product. For example, a glass shampoo bottle (with its cap and label) is a piece of primary packaging, as is the plastic film around a sandwich or the tube of toothpaste. In fact, one guide points out that “the bottle containing the liquid and its label are categorised as primary packaging” for a beverage. All parts of that bottle – the glass jar, the lid, the printed label – are primary packaging because they touch the product and form its final barrier before the consumer.

Primary packaging has several key functions: it prevents contamination and damage, extends shelf life, and delivers product information (ingredients, usage instructions, warnings) to the consumer. It must also reflect the brand and appeal to shoppers through its design and labeling. For instance, preservatives or vacuum seals in food packaging are part of the primary package’s role in extending freshness, while a colorful label on a cereal box connects with the customer.

Examples of Primary Packaging

Primary packages come in many forms. Common examples of primary packaging include:

- Bottles and jars: Glass or plastic containers for liquids and creams (soda bottles, condiment jars, lotion pump bottles).

- Cans: Metal tins for beverages or canned foods (aluminum soft-drink cans, tin cans of soup).

- Flexible film and pouches: Wrappers and laminated bags for snacks, candies, or single-serve items.

- Tubes and dispensers: Squeeze tubes (toothpaste, ointment) or pump-top bottles for sauces and lotions.

- Blister packs: Plastic-and-card packaging that encases pills, electronics, or small toys.

Each of these examples is in direct contact with the product or its contents. For instance, a blister pack’s plastic dome touches the pill inside, and a ketchup bottle’s glass holds the ketchup – all are primary packaging. These primary packages are typically designed to hold the product safely and to be easy for the consumer to open, use, and store.

Many consumer goods illustrate the primary/secondary packaging distinction. Consider bottled beverages: the glass bottle (and its label) is primary packaging because it encloses the drink. If six such bottles are bundled together in a cardboard carrier, that carrier is secondary packaging (it does not touch the liquid but groups the bottles). In fact, a bottle of beer can serve as both primary and secondary packaging – the bottle itself holds the liquid (primary), and when sold loose it also protects the beer in transit (secondary).

Key Functions of Primary Packaging

Primary packaging performs several vital roles:

- Containment: It keeps the product securely within a package to prevent spills or leaks. (Think of tightly sealed food packets or medical vials.)

- Protection: It shields the product from damage and environmental threats. Good primary packages guard against moisture, oxygen, light or impacts that could spoil or break the product. For example, glass provides an inert barrier for juice, while foam or clamshell packs cushion electronics.

- Preservation: It extends shelf life by using features like vacuum sealing, modified atmospheres, or UV coatings. Foods often use airtight pouches or vacuum-jars to slow down oxidation and spoilage.

- Branding and Information: As the first layer consumers see, primary packaging conveys brand identity, ingredients, instructions and warnings. Clear, attractive labeling on a cereal box or drug blister pack helps the consumer make informed choices.

Together, these functions ensure that the product arrives in perfect condition and that the consumer can safely use it. Material choice is critical: plastics, glass, metals or paper are selected based on compatibility with the product (e.g. acidic sauces need certain barriers) and on regulations (food-safe or UN-rated for hazardous goods). Sustainable materials (recyclable plastics, biopolymers, glass) are increasingly used for primary packaging as eco-friendly alternatives.

What Is Secondary Packaging? Grouping and Display Units

Secondary packaging is the next layer out from the primary package. It “goes around primary packaging” to group one or more finished products into a unified pack. The main purposes are to make handling, storage and display easier, and to add another layer of protection. For example, individual cereal boxes (primary) are often packed into a larger cardboard carton that holds a case of six (secondary). Removing the secondary layer does not damage the product; it simply makes the products harder to move and showcase. Secondary packaging is common in many industries (food, cosmetics, over-the-counter meds, beverages) for exactly these reasons.

Secondary packaging also serves marketing and logistical roles. Retailers often buy products on pallets, and secondary packs are designed for those pallets or for shelf display. As one source explains, because secondary packs “are usually on full view, \[they are] fully branded and designed, printed and finished to a high standard” when displayed in stores. In a supermarket, that could be a multipack box of soda cans with bright graphics, or a corrugated tray holding rows of juice cartons. Even when secondary packs aren’t seen by consumers (e.g. plain brown cases for wholesale bulk), they still secure the products during transit and carrying extra information (barcodes, shipping labels).

Examples of Secondary Packaging

Common secondary packaging forms include:

- Cardboard Boxes and Cartons: Corrugated cases that hold multiple units of a product (e.g. a shipping box of soda cans or a carton of paperback books).

- Shrink Wrap and Film: Plastic films wrapped around a bundle of items on a tray or pallet (for example, an 8-pack of water bottles or plastic wrap securing products on a pallet).

- Paperboard Trays: Open-top trays or shelf-ready cartons that hold products upright for retail (often seen with beverages or pharmaceuticals).

- Plastic Crates and Bins: Reusable plastic totes that hold grouped products like fruit or bottles during transport.

- Branded Multipacks and Gift Boxes: Decorative or display-oriented packs (e.g. a six-pack drink carrier, a gift set box of cosmetics) that bundle items and carry prominent branding.

Each of the above is secondary packaging because it groups together products already in their primary packaging. For instance, shrink-wrapping a case of beer bottles or boxing up a set of skincare bottles are secondary packaging examples. These layers often include additional cushioning (padding, cardboard dividers) to protect the primary packs.

Secondary packaging can sometimes double as a selling unit itself. For example, a branded gift box containing a bottle of wine (as shown above) is secondary packaging for the bottle. It carries logos and product information and protects the bottle. In some shipping scenarios, that same box may also act as tertiary packaging if it goes straight to the customer without another outer box. In other words, a single box can serve both to display the product and to ship it, illustrating how packaging layers can overlap in real-world use.

Key Roles of Secondary Packaging

Secondary packaging primarily aggregates individual products into larger units. It simplifies logistics by turning many small units into one bigger unit. For example, palletizing a shipment of boxes would be impossible if each box was handled separately – instead, they stay packed together in cases. Secondary packs also add another protective buffer: they prevent products from shifting and provide crush protection in transit.

Moreover, secondary packaging can carry additional branding and information. As noted, cases and trays are often printed with the brand, model, or barcodes. “Many cases and cartons come with branding, logos, colours, and information concerning the product,” helping customers and warehouse staff identify contents. Even when not on a shelf, this marking aids in inventory management.

Finally, secondary packs can be designed for handling efficiency. Materials like corrugated cardboard are chosen for strength and light weight. Stretch film, strapping, and handles might be added to make lifting or stacking easier. The goal is to make loading trucks, storing on shelves, and handling in warehouses as fast and safe as possible.

Tertiary Packaging: The Outer Bulk Layer

Beyond primary and secondary packaging comes tertiary packaging – the heavy-duty shipping layer. Tertiary packaging includes pallets, crates, large boxes and other transit materials used to move products in bulk. Its sole purpose is to protect secondary (and primary) packages during transportation and handling.

Common tertiary packaging examples include:

- Pallets and Crates: Wooden or plastic pallets on which multiple cases or packages are stacked, often wrapped together.

- Stretch/Shrink Wrap: Plastic film tightly wrapped around pallet loads to secure them.

- Strapping and Banding: Steel or plastic bands that bind cartons on a pallet together.

- Large Shipping Containers: Rigid boxes or standardized containers (cardboard or otherwise) used for intercontinental shipping.

The image above shows a stack of products on pallets: these represent tertiary packaging in action. Anything used to ship or bulk-handle products falls into this category. Importantly, tertiary packaging is usually discarded or recycled before the product reaches the store shelf – its job ends once the goods are safely delivered. Its key role is purely transport protection: as Paramount Global notes, the “primary function of tertiary packaging is holding products during shipping” and encasing the secondary and primary layers in the transit process.

Primary vs Secondary Packaging: Key Differences

Both primary and secondary packages protect products, but in different ways. The table below highlights their main distinctions:

| Aspect | Primary Packaging | Secondary Packaging |

| Contact | Directly touches the product | Surrounds and groups primary packages; no direct contact |

| Purpose | Contains and protects a single unit | Aggregates multiple units for handling, storage and shipping |

| Consumer-facing | Yes – designed for sale/display to end users | Primarily logistical; may be visible (e.g. shelf-ready packs) or hidden (bulk cartons) |

| Branding & Info | Provides branding, labels, and information on the product | Often printed with branding, barcodes or instructions for retailers and shippers |

| Examples | Bottles, cans, jars, pouches, tubes, blister packs | Cardboard boxes, trays, shrink-wrap bundles, multi-packs |

In summary, primary packaging is the product’s immediate container (the “consumer unit”), focused on product protection and presentation. Secondary packaging is the outer grouping of one or more primary units, focused on facilitating distribution and sometimes additional marketing. (Tertiary packaging is the outermost shipping layer, not shown above.) Knowing these roles helps in choosing the right design and machinery for each stage of packaging.

Best Practices and Trends in Packaging

Choosing optimal primary and secondary packaging involves many considerations. SFXB(Xueba) recommends evaluating factors like product size and weight, storage conditions, branding needs, risks to product quality, consumer convenience, shipping method, and budget. For instance, a fragile electronic item (risk factor) might require durable glass and foam (primary), plus reinforced cartons (secondary). A frozen food (storage conditions) demands moisture-proof, low-temperature materials. Branding goals might lead to a custom-printed box as secondary packaging for retail display. Each decision affects product safety, cost and customer satisfaction.

Sustainability and innovation are also driving changes. There is a clear industry trend toward eco-friendly materials – lighter-weight plastics, recycled content, compostable films, and so on. For example, many brands now use recyclable plastics or biodegradable paper in their primary packaging. Lightweighting (using thinner or smaller materials) is common to reduce waste and shipping costs. Even in secondary packaging, companies are replacing plastic shrink-wrap with paper wraps or using less filler in cartons. Consumers increasingly expect “green” packaging, and regulations are encouraging recyclability, so sustainability is now a key design criterion in both primary and secondary packaging.

Packaging Machinery and Efficiency

Effective packaging often requires specialized machinery. Automated equipment can streamline both primary and secondary packaging processes. For example, filling machines accurately dispense liquids or solids into containers, capping machines seal bottles, and labeling machines apply branding and information labels. Secondary packaging benefits from cartoning machines (to erect and fill cases) and palletizing systems (to stack and wrap pallets of finished product). Investing in the right packaging line improves speed, consistency and hygiene. For instance, food manufacturers often use modular automated systems to switch quickly between products while maintaining strict hygiene. In short, pairing well-designed primary/secondary packages with modern machinery is crucial for maximizing throughput and ensuring packaging quality.

Conclusion

Primary and secondary packaging are distinct layers with complementary roles in any supply chain. Primary packaging is the product’s direct container – it contacts the product, keeps it safe and conveys brand identity. Secondary packaging surrounds those primary units, bundling them for easier transportation and sometimes providing extra branding or shelf-display capability. Together (with tertiary packaging for bulk shipping), these layers ensure products reach customers intact and marketable. By understanding each layer’s purpose – and by choosing the right materials, designs and machinery – manufacturers can protect product quality and enhance the consumer experience. Whether it’s selecting a leak-proof plastic bottle (primary) or the perfect corrugated case (secondary), these packaging decisions are critical for safety, efficiency and brand success.

FAQs About Primary Packaging and Secondary Packaging

What is Primary Packaging?

Primary packaging is the first layer of packaging that directly comes into contact with the product. It serves to protect the product and provide information to the consumer. Examples include bottles, blister packs, and tubes.

What is Secondary Packaging?

Secondary packaging is the outer layer that groups primary packages together for easier handling, storage, and transportation. It does not come into direct contact with the product. Examples include cardboard boxes, shrink wraps, and display cartons.

What is Tertiary Packaging?

Tertiary packaging is used for bulk handling and transportation. It groups multiple secondary packages into a single unit for efficient logistics. Examples include pallets, stretch wraps, and crates.

How Do Primary and Secondary Packaging Differ?

Primary packaging directly holds the product and is in contact with it, while secondary packaging groups multiple primary packages together for easier handling and distribution.

Why is Primary Packaging Important?

Primary packaging protects the product from contamination and damage, preserves its quality, and provides essential information to the consumer.

Why is Secondary Packaging Necessary?

Secondary packaging facilitates efficient storage, handling, and transportation of products. It also serves marketing purposes by displaying branding and product information.

Can Secondary Packaging Be Used for Branding?

Yes, secondary packaging provides additional space for branding, product information, and marketing messages, enhancing the product's appeal to consumers.

What Materials Are Commonly Used for Primary Packaging?

Common materials for primary packaging include glass, plastic, metal, and paperboard, chosen based on the product's requirements for protection and preservation.

What Are the Benefits of Tertiary Packaging?

Tertiary packaging ensures safe and efficient transportation of bulk products, reduces handling costs, and protects products during long-distance shipping.

How Do Packaging Types Work Together?

Primary, secondary, and tertiary packaging layers work in tandem to protect the product, facilitate efficient logistics, and enhance consumer experience, ensuring the product reaches the market safely and appealingly.

| References: | |

| 1. | Types of Packaging: Primary, Secondary & Tertiary ——Retrieved from:NMFTA |

| 2. | What are Primary, Secondary, and Tertiary Packaging? ——Retrieved from:MDI |

| 3. | Wikipedia – Packaging |

Comments