In today’s competitive market, product presentation is paramount. A crisp, perfectly placed label not only conveys crucial information but also embodies a brand’s commitment to quality. However, achieving this level of precision across a vast array of packaging shapes—from classic round bottles to flat-surfaced boxes—presents a significant manufacturing challenge. The solution lies in selecting the perfect labeling machine, a decision that directly impacts production efficiency, cost-effectiveness, and brand perception.

This comprehensive guide, brought to you by the experts at SFXB, will delve into the science and engineering behind modern labeling technology. We will explore how to choose the right machine for your specific needs, ensuring every product leaving your facility looks its absolute best. We’ll navigate the complexities of different mechanisms, from the versatile paste labeling machine to highly specialized automated systems.

Understanding the Core Principles: Why One Size Doesn’t Fit All

The fundamental challenge in labeling is the precise application of an adhesive label onto a container surface. The geometry of this surface dictates the entire process. A round bottle requires a different approach than a flat plane or a multi-faceted container. Key variables to consider include:

• Surface Geometry: Is the container cylindrical, tapered, flat, concave, or a complex combination of shapes?

• Label Type: Are you using pressure-sensitive (self-adhesive) labels, wet glue (requiring a paste labeling machine), or sleeve labels?

• Production Speed: How many units per minute or hour do you need to label?

• Accuracy & Positioning: Does the label need to be oriented in a specific location (e.g., aligned with a cap or another design element)?

Failure to match the machine to the application can result in wrinkled, skewed, or poorly adhered labels, leading to product rejection, reputational damage, and financial loss.

For Cylindrical Containers: The World of Round Bottle Labeling

Round bottles are perhaps the most common packaging type for beverages, pharmaceuticals, and cosmetics. The challenge here is to apply the label smoothly without any bubbles or creases as it wraps around a curved surface.

1. The Classic Round Bottle Labeling Machine

A standard round bottle labeling machine is the workhorse of many production lines. It typically uses a wrap-around belt system. As the bottle travels along the conveyor, it is spun on its own axis while a pressure-sensitive label is dispensed and firmly pressed onto its surface. This method is efficient and reliable for full or partial wrap labels on standard cylindrical bottles.

|

| SF-3030 Automatic round bottle labeling machine |

2. For High Precision: The Positioning Labeling Machine

What if your round bottle has a handle, a specific mold mark, or requires the label to be placed in a precise spot relative to another feature? This is where a positioning labeling machine excels. These advanced systems often incorporate sensors (such as photoelectric eyes or cameras) to detect a specific feature on the bottle. The machine then rotates the bottle to the exact orientation before applying the label. This ensures unparalleled consistency, which is critical for premium products where every detail matters.

|

| SF-3040 Automatic round bottle positioning and labeling machine |

3. Unstable & Small Diameter Bottles: The Horizontal Labeling Machine

Labeling small, unstable cylindrical items like ampoules, vials, lipstick tubes, or pens poses a unique challenge. These items cannot stand upright stably on a conveyor. The solution is the horizontal labeling machine. This machine places the bottle on its side onto rollers. The bottle is then rotated and the label is applied from above. This horizontal orientation provides the stability needed for a precise and secure wrap, making it an indispensable tool in the pharmaceutical and cosmetic industries.

|

| SF-3020 Horizontal roll labeling machine |

4. The Specialized Static Fixing Round Bottle Labeling Machine

For applications demanding the absolute highest degree of accuracy, especially for wrap-around labels on high-end spirits or wine bottles, the static fixing round bottle labeling machine is the ultimate choice. This machine brings the bottle to a complete stop at the labeling station. It then uses a sophisticated multi-roller system or a precise clamping mechanism to rotate the bottle in place while the label is meticulously applied. While slower than continuous motion machines, the static application process eliminates almost all variables that could cause slight misalignments, delivering a flawless finish.

|

| SF-3042 Automatic astrolabe fixed-point positioning round bottle labeling machine |

For Flat and Irregular Surfaces: Beyond the Bottle

Not all products come in round containers. Boxes, cartons, jars with flat sides, and electronic components all require a different approach.

The Versatile Plane Labeling Machine

As the name suggests, a plane labeling machine (also known as a top-and-bottom or flat-surface labeler) is designed for applying labels to flat surfaces. These machines can be configured in several ways:

• Top Labeling: A labeling head is positioned above the conveyor to apply labels to the top surface of products like boxes, lids, or books.

• Bottom Labeling: The labeling head is placed below a split-belt conveyor to apply labels to the underside of a container.

• Side Labeling: For applying labels to the sides of square or rectangular containers.

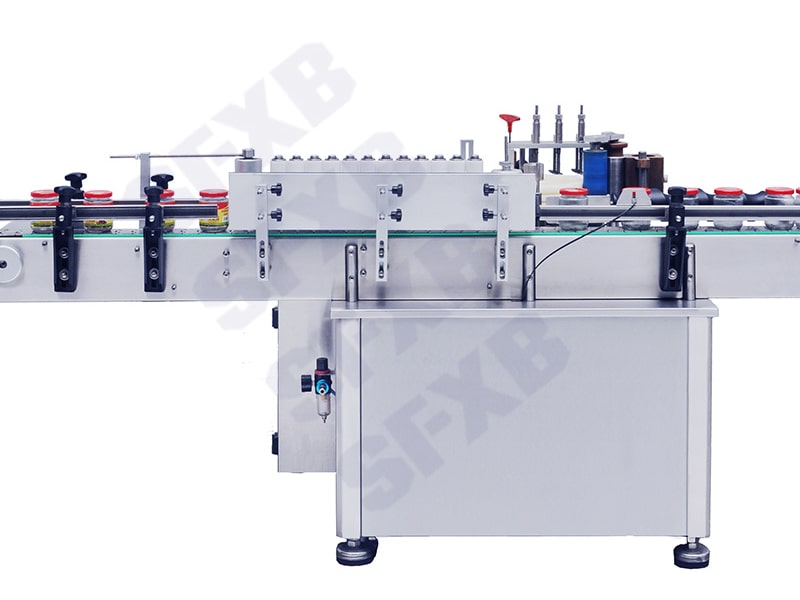

For products requiring labels on both the front and back, a dual-side labeling machine is the most efficient solution. This machine uses two opposing labeling heads to apply labels to two sides of a container simultaneously as it passes between them. This is essential for food, personal care, and household chemical products that need to display branding on the front and nutritional or regulatory information on the back. The key to a good dual-side labeling machine is its ability to ensure both labels are perfectly parallel and at the same height.

The Enduring Relevance of the Paste Labeling Machine

While pressure-sensitive labels dominate many sectors, the traditional wet glue labeling method, which utilizes a paste labeling machine, remains highly relevant and cost-effective in specific industries.

A paste labeling machine works by applying a thin, even layer of cold or hot melt glue to a paper or foil label just before it is applied to the container. The machine then uses a combination of pads and brushes to wipe the label down, ensuring a strong, permanent bond.

|

| SFJH-10 Automatic Paste Labeling Machine |

Advantages of a Paste Labeling Machine:

• Cost-Effectiveness: Paper labels and glue are often significantly cheaper than pre-made pressure-sensitive label stock, especially for very high-volume production runs (e.g., beer and food canning industries).

• Durability: The wet glue application can create an extremely strong bond that is resistant to moisture and temperature changes.

• Flexibility: These machines can often handle a wider range of label papers and container materials.

Choosing a paste labeling machine is a strategic decision often made in the beverage and canned goods industries where billions of units are produced annually and even a fractional saving per label translates into millions of dollars in savings.

How to Make the Right Choice: A Technical Checklist

Selecting the ideal labeling machine is a critical investment. Here at Xuebapack, we guide our clients through a detailed analysis based on the E-E-A-T (Experience, Expertise, Authoritativeness, Trustworthiness) framework.

1.Analyze Your Container:

● Shape & Dimensions: Measure every surface. Is it a simple cylinder or a complex, multi-faceted shape?

● Material: Glass, PET, HDPE, metal? The surface energy and texture of the material affect label adhesion.

● Consistency: Are your containers uniform, or is there variability from your supplier?

2.Analyze Your Label:

● Type: Pressure-sensitive, wet glue, or sleeve? This is the first and most critical decision point.

● Size & Material: The label’s size and stiffness will influence the application method.

● Placement: Where does the label go? Is it a full wrap, a spot label, front-and-back, or a top label? Does it require precise orientation?

3.Analyze Your Production Line:

● Speed: Calculate your required throughput in pieces per minute (PPM). Choose a machine that can comfortably exceed this to allow for future growth.

● Integration: How will the labeling machine fit into your existing conveyor system? Consider space, power requirements, and data connectivity.

● Changeover: How often will you switch between different products/labels? Look for machines with tool-less adjustments and digital controls (like a positioning labeling machine with stored recipes) to minimize downtime.

4.Trust Your Partner:

● Expertise: Partner with a manufacturer like Xuebapack who demonstrates deep technical knowledge and can showcase successful case studies.

● Support: Ensure your supplier provides installation, training, and readily available technical support and spare parts. A machine is only as good as the service that backs it up.

Conclusion: Precision Labeling as a Competitive Advantage

Choosing the right labeling machine is far more than a simple procurement decision; it is a strategic investment in your brand’s quality and your operational efficiency. From the high-speed efficiency of a dual-side labeling machine for household goods, to the delicate precision of a horizontal labeling machine for vials, to the cost-effective power of a paste labeling machine for canned foods, the correct technology is available for every conceivable packaging shape.

By scientifically evaluating your container, label, and production needs, you can select a machine that not only performs its function flawlessly but also provides a significant return on investment. The result is a perfectly presented product that stands out on the shelf, builds consumer trust, and drives your business forward.

Frequently Asked Questions (FAQs)

1. What is a labeling machine?

Answer: A labeling machine is an automated device used to apply labels precisely to various types of packaging containers. These machines can handle different shapes and sizes of containers, including round bottles, flat boxes, and other types of packaging. Common types of labels used are pressure-sensitive labels, wet glue labels, and sleeve labels.

2. How do I choose the right labeling machine for my packaging containers?

Answer: When selecting a labeling machine, consider the shape, size, and material of your packaging containers, as well as the type of label used. For example, round bottles are best suited for round bottle labeling machines, while containers that require precise label placement may require a positioning labeling machine. Factors such as production speed, label accuracy, and ease of operation are also crucial.

3. What is a positioning labeling machine?

Answer: A positioning labeling machine is a high-precision labeling device used when labels need to be applied to a specific location on the container. It typically uses sensors or camera systems to detect a feature on the bottle, then rotates the bottle to the correct position before applying the label. This ensures exact alignment, especially for premium products where label placement is critical.

4. Which industries use labeling machines?

Answer: Labeling machines are widely used across industries like food and beverage, pharmaceuticals, cosmetics, and household chemicals. They are commonly used for labeling beverage bottles, pharmaceutical containers, cosmetic products, food cans, and household goods.

5. What is the difference between a wet glue labeling machine and a pressure-sensitive labeling machine?

Answer: A wet glue labeling machine uses glue to apply labels to containers, which is ideal for high-volume industries like beverage and canned goods. A pressure-sensitive labeling machine uses self-adhesive labels, offering a more straightforward operation, and is widely used in industries such as cosmetics, pharmaceuticals, and food packaging.

6. What products are suitable for a horizontal labeling machine?

Answer: A horizontal labeling machine is ideal for small, unstable cylindrical items such as ampoules, vials, lipstick tubes, and pens. These items cannot stand upright on a conveyor, and the horizontal machine places them on their side, rotates them, and applies the label from above for precise and secure labeling.

7. How can I improve the efficiency of my labeling machine?

Answer: To improve labeling machine efficiency, consider selecting a model that matches your production needs, increase automation levels, reduce changeover time between different products, and ensure regular machine maintenance. Additionally, integrating the labeling machine seamlessly into your production line can help streamline the entire process.

8. What maintenance is required for a labeling machine?

Answer: Regular maintenance of a labeling machine involves checking and cleaning key components like label sensors, conveyors, and label rollers. Ensuring the glue or adhesive quality is up to par and replacing worn-out parts promptly can extend the machine’s lifespan and reduce downtime.

9. What types of containers can labeling machines handle?

Answer: Labeling machines are capable of handling a variety of container shapes, including round bottles, square containers, flat surfaces, and irregularly shaped items. Different types of machines are available for each shape, such as round bottle labeling machines for cylindrical containers, and customized machines for more complex shapes.

10. What are the advantages of a wet glue labeling machine in the food industry?

Answer: Wet glue labeling machines are particularly advantageous in high-volume production, such as in the beverage and canned food industries. They are cost-effective for large production runs, providing a strong bond that resists moisture and temperature changes, making them ideal for environments like food canning where large quantities are produced and cost savings are crucial.

| References: | |

| 1. | Advanced Labeling Machinery and Its Impact on Production Lines ——Retrieved from: ResearchGate |

| 2. | The Evolution of Wet Glue Labeling ——Retrieved from: Food Engineering Magazine |

| 3. | The Role of Labeling in Consumer Perception ——Retrieved from:ScienceDirect |

| 4. | Labeling and Packaging Industry Overview ——Retrieved from:Packaging World |

| 5. | Packaging and Labeling Technology Handbook ——Retrieved from:Amazon |

Comments