Packaging kimchi – Korea’s beloved fermented cabbage – presents unique challenges. Kimchi continues to ferment in the bag, generating carbon dioxide and acids, so its package must preserve freshness, contain pungent aromas, and prevent leaks. Modern kimchi packaging solutions leverage specialized premade pouches and advanced machinery to meet these needs. In this article, we explore how flexible pouches, vacuum systems, and active packaging features combine to protect kimchi’s quality and extend its shelf life – all while delivering convenience and appeal to consumers.

Unique Challenges in Kimchi Packaging

Kimchi is a live fermented food. Its lactic acid bacteria conversion of sugars produces CO₂ gas and lactic acid over time. As a result, pressure can build inside a sealed package, potentially causing bulging or bursts. Excess oxygen or moisture ingress can also spoil kimchi by accelerating unwanted fermentation or microbial growth. Therefore, kimchi packaging must strike a balance: it should prevent external oxygen from entering, allow excess CO₂ to escape, and withstand acidity and moisture. Special attention is needed to seal the spicy, wet brine securely and maintain a cool, controlled environment during storage.

Research confirms the importance of managing internal gases. In controlled studies of kimchi storage, packages that were vacuum-sealed or flushed with CO₂ showed higher CO₂ production (from fermentation) than air-filled packages. However, an initial vacuum treatment kept internal pressure lower over time, and a properly designed gas-flush helped dissolve some CO₂ into the brine. In practice, this means advanced packaging often combines vacuum filling with gas flushing to reduce package inflation and preserve the ideal “carbonic” flavor of ripe kimchi. Some producers even include CO₂-absorbing sachets (filled with zeolite or activated carbon) inside the pouch. These absorbers capture excess fermentation gas in a time-dependent way, preventing overpressure and maintaining a pleasant effervescence. In summary, effective kimchi packaging solutions actively control the internal atmosphere to avoid blown-out pouches and to keep kimchi tasting fresh.

Premade Stand-Up Pouch Packaging

One of the most popular formats for kimchi is the premade stand-up pouch (often with a bottom gusset). Stand-up pouches (doypacks) are flexible bags that can stand upright on shelves even when empty. They typically feature resealable zippers, tear notches, and hang holes for consumer convenience. These pouches come pre-manufactured and are fed into a filling machine, which opens, fills, and seals each pouch. Compared to forming bags from film reels, using premade pouches offers ultimate flexibility: manufacturers can quickly switch between sizes or designs without changing film rolls. This is especially valuable for small-batch or custom kimchi producers with many SKUs.

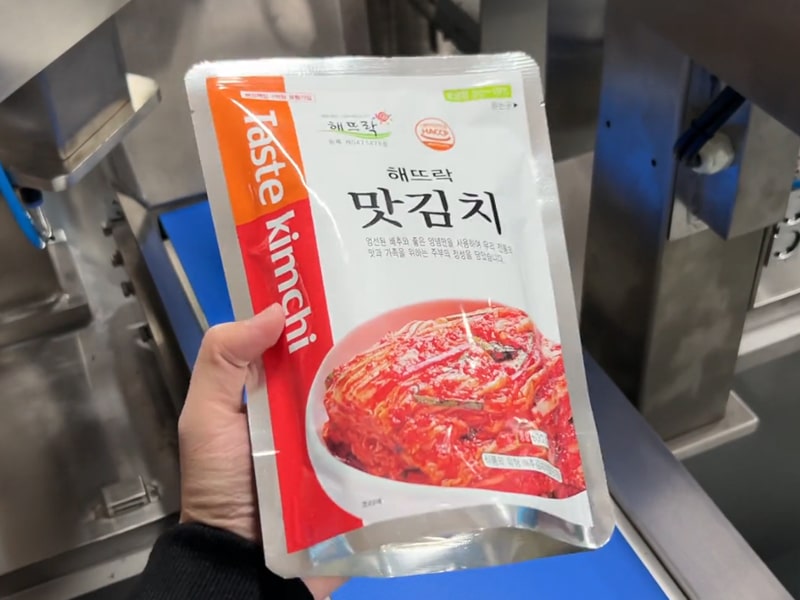

Figure: Example of a flexible stand-up pouch. Modern kimchi packaging pouches often include resealable closures and even gas-release valves to handle fermentation gases.

Stand-up pouches are favored because of their marketing and functional benefits. They maximize graphics and shelf appeal on grocery store shelves. The bottom gusset expands when filled, giving a full, stable package shape. Customers can reseal the pouch after opening, which helps keep kimchi fresh in the refrigerator. These pouches are constructed from multilayer barrier films (e.g. PET/PE/nylon laminates) that block moisture and oxygen effectively. By keeping oxygen out and optionally using vacuum or inert-gas flushing inside, stand-up pouches slow oxidative spoilage of kimchi, helping to preserve its quality longer. Additional features like integrated gas-release valves allow CO₂ to vent gently (while blocking air entry), preventing pouch inflation and keeping the texture intact. In short, premade stand-up pouches combine convenience and high-barrier protection, making them ideal for packings like pickles and kimchi.

Advanced Packaging Technologies for Kimchi

To address kimchi’s fermentation, advanced pouch packaging uses a combination of technologies:

- Vacuum Filling and Sealing: Many kimchi pouch lines first vacuum out air before sealing. This removes oxygen and leaves mostly CO₂ (or even creates negative pressure) inside. Vacuum sealing slows the ripening process and prevents gas-induced burst of the pouch. Modern machines integrate vacuum chambers, ensuring each pouch is sealed under low pressure. In fact, specialized vacuum pouches (with strong seals) are used for pickles and kimchi.

- Modified Atmosphere (Gas Flush): Immediately after filling, some lines inject a small amount of carbon dioxide or nitrogen gas into the pouch before final sealing. Flushing with CO₂ matches the headspace to the expected fermentation gases and can suppress aerobic spoilage. As experiments show, a timed CO₂ flush can maintain a high internal CO₂ level and give kimchi a mild fizzy tang, without dangerous pressure buildup.

- Pressure-Relief Valves: Pouches can be made with tiny one-way valves that vent excess gas. These valves allow carbon dioxide (from kimchi) to escape slowly but prevent outside air from entering. This kind of smart venting prevents over-pressurization. For example, stand-up pouches can be equipped with microvalves designed for kimchi and sauerkraut, maintaining package integrity as fermentation continues.

- CO₂ Absorbing Materials: As research demonstrates, embedding CO₂-absorbent sachets (zeolite or activated carbon) in the pouch can actively regulate pressure. The absorbents capture excess CO₂ during storage and slowly re-emit it if needed, effectively smoothing out pressure spikes. This approach not only prevents blown pouches, but also imparts a mild carbonic (sparkling) mouthfeel to the kimchi – a desirable quality note noted by tasters.

- Temperature Control: Some packaging lines incorporate chilled filling or supercooling to slow fermentation during production. Lower temperatures reduce gas production rate, giving the packaging process more tolerance. (Note: Overcooling too much can change texture, so this is carefully controlled.)

These technologies – vacuum-sealing, gas flushing, valves, and absorbents – are often used together. The result is a high-tech packaging solution tuned for kimchi’s unique fermentation profile.

Materials and Construction

High-performance kimchi pouches rely on engineered film materials. Multilayer laminates are the norm. Common structures include combinations like PET/NY/PE (polyester/nylon/polyethylene) or PET/AL/NY/PE (adding aluminum). Each layer serves a purpose: one layer provides mechanical strength, another provides an oxygen barrier, and another provides a heat-sealable inner surface. For example, a nylon layer resists puncture from kimchi’s chili seeds, while aluminum or metallized PET greatly limits oxygen transmission.

Stand-up pouches specifically may use metallized films or extra PET for higher barrier. The industrial standard is to achieve “zero” oxygen ingress (food-grade specification) to maintain kimchi quality. Films must also resist moisture and acid: PE and PET layers are chemically inert, preventing acidic brine from corroding the package. In sum, the pouch acts as a mini fermentation chamber: durable and airtight, but often with the engineered ability to release or capture gas as needed.

Importantly, packaging materials used must be food-safe and approved for fermented products. Many kimchi companies use certified food-grade films compliant with regulatory standards. The choice of film is balanced between cost and performance: higher barrier (often achieved with thicker or metalized films) gives longer shelf life but at higher cost. For export-quality kimchi, the extra shelf life is usually worth it. Some producers even use compostable or recyclable pouches made from barrier biopolymers, reflecting an eco-friendly trend (though such pouches must still meet barrier requirements).

In addition to film, closures and accessories are part of the pouch design. Zip-lock or slider zippers provide reclosure. Tear notches allow easy opening. A small spout and cap can be fitted to some pouches if a pour-out feature is desired. As noted by packaging experts, incorporating these features adds consumer convenience and gives kimchi producers flexibility in how end-users consume and store the product.

High-Efficiency Kimchi Packaging Machinery

Behind these advanced pouches are equally advanced packaging machines. A premade pouch filling machine automates the entire process: pouch feeding, opening, filling, gas treatment, and sealing. Modern machines combine multiple systems in one frame. For kimchi, a typical rotary or linear premade pouch machine might include:

- A bag feeder system that takes pre-formed pouches from stacks or tape, inverting and presenting each bag.

- A bag opening mechanism that uses vacuum suction cups or clamps to hold the pouch upright and open it fully.

- An optional vacuum chamber (for vacuum filling) that evacuates air from the open pouch before product insertion.

- A multi-head or auger filler that precisely dispenses kimchi or kimchi pieces and brine into each open pouch.

- A gas flushing system that injects controlled CO₂/N₂ gas into the pouch headspace before final sealing.

- A sealing head (heat or impulse sealing) that closes the pouch, often under maintained pressure.

- Quality-control features like checkweighers or metal detectors on the discharge conveyor.

Many machines are built on 304 stainless steel frames and contact parts – as one manufacturer notes, “304 SS guarantees durability and hygiene”. This ensures compliance with food safety and allows for easy cleaning. Advanced machines also use PLC/Siemens controls for precise automation and have sensors to verify each step. For example, an automatic bag-width adjustment uses servo motors to center and open pouches of different sizes without manual changeover. These features increase throughput and flexibility.

Typical production speeds depend on pouch size and complexity. For instance, a 100–200 g kimchi pouch machine might run 40–60 bags per minute under vacuum conditions. The machinery list often includes options like filling weighers, conveyors, and in-line checkweighers to create a complete filling line. In one example equipment catalog, a rotary vacuum pickle/kimchi packaging machine is rated at 40–55 bags/min. Such high-speed lines enable brands to pack large volumes efficiently.

Aside from standard filling machines, some producers may use modified lines. For example, a dedicated kimchi line could include an ultrasonic gas release station to perforate a tiny vent hole if needed, or an in-line nitrogen generator to feed gas flushing. All major packaging equipment suppliers now offer models specifically designed for sauces, pickles, and fermented foods, with material-contact parts built to resist acidity and with sanitary designs to prevent contamination.

Ensuring Quality and Consumer Appeal

Beyond the technical machinery, packaging design plays a big role in consumer acceptance. Premium kimchi brands invest in vibrant printing and convenient features on their pouches. Full-color flexographic printing on multi-layer film can display the product clearly (sometimes with a window), and tell consumers about fermentation times or spiciness. Many successful packages combine visual appeal with informative labeling (ingredient lists, nutrition facts, fermentation date).

Safety features are also important for expert-level trust. Good practices include tamper-evident seals or tear-off strips, ensuring customers that the kimchi wasn’t opened before purchase. Anti-counterfeiting measures like QR codes or blockchain track-and-trace tags are emerging in fermented foods too.

Finally, modern packaging strives for sustainability without compromising performance. Kimchi pouches are often partially recyclable (though multi-layer films are harder to recycle than single polymers). Some firms are exploring mono-material laminates or biodegradable films with barrier coatings. These innovations are still maturing, but they reflect an industry trend toward greener packaging solutions.

Conclusion

In sum, kimchi packaging solutions have evolved into a high-tech field. By combining premade stand-up pouches, multi-layer barrier films, and advanced filling machinery, producers can preserve the live fermentation culture of kimchi while delivering convenience to consumers. Key innovations—vacuum sealing, modified-atmosphere gas flushing, CO₂-vent valves and absorbers—address the unique fermentation challenge head-on. At the same time, modern machinery ensures consistency and hygiene (for example, 304 SS construction).

The result is a packaging system that keeps kimchi flavorful and safe from production to consumption. Properly designed premade pouches extend shelf life, prevent leaks, and allow the kimchi to continue breathing just the right amount. As demand for kimchi grows globally, these advanced pouch packaging technologies are essential for any manufacturer looking to deliver authentic, high-quality kimchi to the market.

Frequently Asked Questions (FAQ) About Kimchi Packaging

1. What makes kimchi packaging different from other food packaging?

Kimchi packaging must handle active fermentation, moisture, acids, and CO₂ generation. It requires high-barrier films and pressure-release mechanisms (valves or absorbers) to prevent pouch bloating, leaks, and spoilage.

2. Why use premade stand-up pouches for kimchi?

Premade pouches (doypacks) offer flexibility, cost-efficiency, and convenience. They allow fast product and design changes, feature resealable zippers, and support barrier films to preserve freshness. Their stable, attractive shape also enhances shelf presence.

3. How do gas-release valves and CO₂ absorbers help kimchi stay fresh?

Gas-release valves vent CO₂ to avoid overpressure, while one-way valves prevent oxygen entry. CO₂-absorbing sachets regulate internal pressure and preserve the desirable mild fizz of fermented kimchi. These features protect both pouch integrity and product quality.

4. What is the role of vacuum filling and gas flushing in kimchi packaging?

Vacuum filling removes oxygen and triangular pressure, aiding freshness. Gas flushing (with CO₂ or nitrogen) stabilizes internal atmosphere and enhances microbial safety, slowing oxidative and aerobic growth.

5. What materials are used for high-barrier kimchi pouches?

Kimchi pouches use multilayer laminates such as PET/NY/PE or PET/AL/NY/PE, which are strong, acid-resistant, and impermeable to gas and moisture. Aluminum or metallized films offer superior barrier properties.

6. How fast can kimchi pouch packaging machines run?

Modern pre-made pouch machines can operate at up to 60 bags per minute, with rotary vacuum pickle/kimchi machines achieving 40–55 bags/min. High-speed models can even reach 3,600 bags/hour.

7. What safety and hygiene features are standard on kimchi pouch machines?

These machines typically include:

• 304 stainless-steel contact parts for food safety

• PLC/HMI controls with fault indicators

• Safety guards with automatic shutdown

• Oil-free vacuum pumps to prevent contamination

8. Can kimchi packages expand or bloat after fermentation?

Yes. As kimchi ferments, CO₂ naturally builds inside airtight packaging, causing bloating. This is normal and safe, as long as one-way valves or periodic "burping" prevents over-inflation.

9. Should I refrigerate packaged kimchi?

Yes. Refrigeration slows fermentation and gas buildup. If left at room temperature, CO₂ accumulation must be managed by burping packages regularly to release pressure.

10. How should kimchi be shipped safely?

Kimchi should be sealed in multiple layers (e.g., zip bags plus outer insulation), packed with ice packs or insulated wraps, and shipped via fast refrigerated methods to prevent degradation—or package it in cooled containers with vent valves.

| References: | |

| 1. | The use of physical carbon dioxide absorbent to control pressure buildup and volume expansion of Kimchi packages ——Retrieved from:ResearchGate |

| 2. | Modified Atmosphere Packaging Technology of Fresh and Fresh-cut Produce and the Microbial Consequences—A Review ——Retrieved from:National Library of Medicine |

| 3. | Stand-Up Pouch Technology Overview ——Retrieved from:Wikipedia |

Comments