I. Introduction: Unveiling the World of Jam Packaging

The Sweet Science of Preservation: Why Packaging is Paramount

Jam, a beloved staple found on breakfast tables and in gourmet desserts worldwide, embarks on a complex journey from its origin as fresh fruit to its final consumption. At the heart of this journey lies packaging—a sophisticated system far beyond a mere container. It is a critical discipline integrating material science, precision engineering, stringent food safety protocols, and strategic marketing. The selection and implementation of appropriate packaging are not just about containment; they are about ensuring the product’s safety, maintaining its quality, and enhancing its appeal in a competitive market. This multifaceted approach is fundamental for achieving consumer satisfaction and driving brand success.

The discipline of jam packaging represents a continuous scientific and engineering endeavor. It involves understanding the chemical and physical interactions between the jam and its container, developing advanced barrier technologies, and designing efficient, hygienic production lines. This complexity from the outset establishes the critical nature of packaging in the food industry, positioning it as a pivotal area for strategic investment and innovation. The evolution of jam packaging reflects a journey from rudimentary preservation methods to the highly advanced industrial solutions available today, driven by scientific advancements and evolving consumer demands.

What This Ultimate Guide Covers

This comprehensive guide delves deep into the intricate world of jam packaging. It explores the diverse array of packaging materials available, dissecting their scientific properties, advantages, and limitations. The discussion then transitions to the intricacies of industrial filling and sealing processes, highlighting the technological advancements that ensure precision and efficiency. A critical segment is dedicated to navigating the complex landscape of regulatory compliance and food safety standards, emphasizing their non-negotiable role in market access and consumer trust. Furthermore, the report examines the strategic importance of secondary packaging in logistics and brand presentation. Finally, it explores the exciting emerging trends that are poised to redefine the future of jam packaging, from sustainability innovations to advanced automation.

II. The Fundamental Role of Jam Packaging: Beyond Just a Container

Jam packaging serves a dual, interconnected purpose: it acts as a robust shield for the product and a powerful ambassador for the brand. This dual role necessitates a delicate balance between engineering for protection and designing for market appeal.

Safeguarding Quality: Protection Against Spoilage Factors

The primary and most critical function of jam packaging is to protect the delicate product from external elements that cause degradation. These detrimental factors include moisture, atmospheric oxygen, harmful ultraviolet (UV) light, and various microorganisms. Effective packaging is engineered to create robust barriers against these threats. For instance, flexible packaging solutions, such as pouches, and rigid options, like metal tins, are specifically designed to block out moisture and microorganisms, ensuring the jam’s quality remains uncompromised throughout its journey from the production line through transportation and storage. This protective function is paramount for maintaining the product’s integrity and safety over time.

Extending Shelf Life and Preserving Sensory Attributes

Effective packaging directly contributes to extending the product’s shelf life, a vital factor for manufacturers, distributors, and retailers. A longer shelf life translates into reduced waste, greater logistical flexibility, and broader market reach. Beyond mere preservation, superior packaging meticulously maintains the jam’s original aroma, authentic flavor, vibrant color, and desirable texture. This consistency is paramount for delivering a delightful consumer experience and reinforcing the brand’s commitment to quality. The ability of packaging to effectively protect the product from moisture, air, and microorganisms directly extends its shelf life and preserves its sensory attributes, ensuring that consumers taste the original jam as intended.

Enhancing Brand Appeal and Consumer Trust

The aesthetic and informational aspects of packaging are equally critical. Attractive designs, vivid colors, and clear, legible product information—such as production date, expiration date, and ingredients—are essential for capturing consumer attention on crowded retail shelves. These elements significantly influence initial purchase decisions and foster long-term brand loyalty. When consumers can easily discern product details and are drawn to the visual presentation, it creates a positive first impression.

The physical integrity of the packaging also plays a profound role in shaping consumer perception. Durable packaging, capable of withstanding the rigors of handling and shipping, directly prevents product damage. This reliability significantly influences customer trust and encourages repeat purchases. When a product arrives intact and visually appealing, especially with transparent packaging like glass jars that allow consumers to see the jam’s color and texture, it signals quality and care from the brand. This positive experience builds trust. Conversely, a damaged or visually obscured product can erode trust, regardless of the jam’s actual quality. Therefore, the investment in quality packaging, and the machinery required to produce it, becomes an investment in brand equity and enduring customer relationships. The strategic decision-making in packaging design involves balancing robust barrier properties with aesthetic appeal and cost-effectiveness, recognizing that packaging is not just a logistical necessity but a powerful marketing tool.

III. A Deep Dive into Jam Packaging Materials: Properties, Pros, and Cons

The choice of packaging material is a foundational decision in jam production, influencing everything from preservation and shelf life to brand perception and environmental impact. Each material offers a unique set of properties, advantages, and disadvantages.

Glass Jars: The Timeless Classic

Glass jars remain a traditional and highly favored choice for jam packaging. They are primarily composed of abundant natural materials: silica (sand), soda ash, and limestone, which are heated and molded into desired shapes. Scientifically, glass is renowned for its chemical inertness, meaning it is non-reactive with acidic contents like jams. This crucial property ensures that the authentic flavor, aroma, and color of the product are preserved without chemical interaction or taste transfer. Furthermore, glass is virtually impermeable, forming an excellent barrier against gases and particles, and its transparency allows consumers to visually assess the product, which is a key selling point for jams with appealing fruit chunks. Glass is tasteless and odorless, ensuring no foreign flavors are imparted to the jam.

Glass offers a premium aesthetic appeal, often favored by artisanal and premium brands, conveying a sense of quality and tradition. It is highly reusable and infinitely recyclable without loss of quality, making it an eco-friendly option that resonates strongly with environmentally conscious consumers. Scientific research consistently confirms glass’s superior ability to preserve product flavor and quality compared to other materials.

Despite its many benefits, glass has notable drawbacks. Its inherent weight contributes to higher transportation costs, and its fragility increases the risk of breakage and product loss during handling and shipping. The manufacturing process for glass is also energy-intensive due to the high temperatures required to melt raw materials.

|

| Jam Packaging Materials:Glass Jars |

Plastic Containers: Versatility and Modernity

Plastic jam containers are typically made from various polymers, each with distinct properties. Common types include Polyethylene Terephthalate (PET), Polypropylene (PP), High-Density Polyethylene (HDPE), Polyvinyl Chloride (PVC), and newer acrylics. PET is known for its clarity and superior thermal insulation, offering good resistance to photodegradation. PP offers excellent chemical resistance, durability, and high-temperature resistance, with good optical clarity and low moisture transmission.7 HDPE is recognized for its strength, impact resistance, and ability to withstand low temperatures, often used for its good moisture barrier properties.

Plastic containers are highly valued for their lightweight nature, which significantly reduces transportation costs, and their durability, being shatterproof. They offer immense design flexibility, allowing manufacturers to mold them into a wide variety of shapes and sizes to stand out on shelves. Their cost-effectiveness makes them a popular choice for companies aiming to optimize packaging expenses.

A primary concern with plastic packaging is its environmental impact, as not all types are easily or widely recyclable, leading to ongoing sustainability challenges. While versatile, plastics can have barrier limitations compared to glass or metal for certain applications. However, advancements in multi-layer plastics, such as co-extruded PP/EVOH/PP bottles, effectively address this by incorporating key barrier materials like Ethylene Vinyl Alcohol Copolymer (EVOH) to block oxygen and other gases, significantly improving preservation and extending shelf life. This continuous innovation in plastic engineering demonstrates a commitment to overcoming inherent material limitations while meeting evolving consumer demands for convenience and sustainability.

|

| Jam Packaging Materials:Plastic Containers |

Metal Cans: Robust Protection for Long-Term Storage

Metal containers used for jam are typically manufactured from tin-plated steel or aluminum. These materials offer a high degree of durability and protection, making them suitable for various food products.

Metal cans offer superior barrier properties against light, air, and moisture, which are critical for preserving the jam’s quality over extended periods, sometimes up to five years. They are exceptionally durable, capable of withstanding rough handling during transportation, thus minimizing damage and product loss. Both aluminum and steel are easily recyclable, contributing to their eco-friendly profile. Aluminum, in particular, is lighter than glass, further reducing transportation risks and costs.

A significant drawback of metal cans is their opacity, which prevents consumers from visually inspecting the jam inside, potentially reducing its shelf appeal compared to transparent options like glass. Crucially, metal can react with acidic food products like jams, leading to corrosion if not properly protected. However, this is largely mitigated in modern containers, which are lined with food-safe polymer coatings to prevent interaction and preserve freshness. Metal containers can also be heavier and more costly to transport than some plastic alternatives.

|

| Jam Packaging Materials:Metal Cans |

Flexible Packaging Solutions: Convenience and Innovation

Flexible packaging is gaining immense popularity due to its lightweight nature, versatility, and space-saving design. This category encompasses a range of innovative solutions tailored for modern consumer lifestyles.

Pouches (Stand-Up, Spouted): Flexible pouches are often resealable, making them highly convenient for consumers. They are particularly ideal for jams with a runnier consistency, allowing for easy squeezing and portion control. Various styles exist, including stand-up pouches, spouted pouches (perfect for children’s products), flat bottom bags, and doypack bags. Pouches are lightweight and take up less space, making them efficient for storage and transport.

|

| Jam Packaging Materials:Pouches (Stand-Up, Spouted) |

Tubes: Jam tubes offer exceptional convenience for on-the-go consumption. Their design allows for controlled dispensing, minimizing mess and waste. They are easy to squeeze and typically feature resealable screw caps, making them highly practical for single-serve portions, picnics, or travel.

|

| Jam Packaging Materials:Tubes |

Stick Packs & Blister Packs: These small, individual packages are designed for single use, offering ultimate convenience and precise portion control. Stick packs are typically long, narrow cylinders, while blister packs feature individual pockets often sealed with an aluminum foil layer. They are perfect for applications in cafes, hotels, or for travel-sized jam sampler portions.

|

| Jam Packaging Materials:Stick Packs & Blister Packs |

Multi-Layer Films: Advanced Barrier Properties for Optimal Preservation: Flexible packaging achieves high levels of protection through the sophisticated engineering of multi-layered films. Each layer in these structures contributes a specific barrier function, such as resistance to gas (oxygen), light (UV rays), moisture, or microbial ingress. Common materials include EVOH (ethylene vinyl alcohol) for oxygen resistance, PVDC (polyvinylidene chloride), metallized films (thin layers of aluminum over plastic films for light and gas barriers), and even innovative edible films designed to control moisture and deliver antioxidants. This increasing adoption of flexible packaging, particularly multi-layer films, signifies a strategic shift towards highly engineered solutions that can mimic or even surpass the barrier properties of rigid materials while offering significant cost and logistical advantages. This trend directly impacts the demand for specialized filling and sealing machinery capable of handling these advanced films efficiently.

The continuous evolution of packaging materials demonstrates a relentless scientific pursuit to overcome inherent material limitations—such as glass fragility, plastic permeability, or metal reactivity—while simultaneously meeting evolving consumer demands for convenience and sustainability. This highlights the dynamic and innovative nature of the packaging science field, where manufacturers must continuously adapt and invest in versatile machinery to process these diverse and technically advanced materials.

Table 1: Comparative Analysis of Primary Jam Packaging Materials

| Material Type | Key Properties | Advantages (Summary) | Disadvantages (Summary) | Typical Jam Applications |

| Glass Jars | Inert, Transparent, Impermeable, Rigid | Premium aesthetic, taste preservation, reusable, infinitely recyclable | Heavy, fragile, higher transport costs, energy-intensive manufacturing | Premium/Artisanal jams, Gifting, Home use |

| Plastic (PET, PP, HDPE) | Lightweight, Durable, Versatile shapes, Variable transparency/barrier | Cost-effective, shatterproof, reduced transport costs, design flexibility | Environmental concerns (some types), potential barrier limitations (for single-layer), less premium perception than glass | Mass Market, Cost-effective, Everyday use |

| Metal Cans (Aluminum, Tin-plated Steel) | Opaque, High barrier (light, air, moisture), Durable, Lightweight (Aluminum) | Superior protection, long shelf life, highly durable, recyclable | Opacity (no product visibility), potential reactivity with acid (if uncoated), heavier than plastic | Bulk, Long-term storage, Industrial use |

| Flexible (Pouches, Tubes, Stick Packs) | Lightweight, Versatile, Resealable, Multi-layer barrier | Convenience, portability, space-saving, reduced shipping costs, portion control | Susceptible to punctures, can be perceived as less premium (vs. glass) | Single-serve, On-the-go, Kids’ products, Jam Sampler packs |

IV. Industrial Jam Packaging Processes: From Filling to Sealing Excellence

The journey of jam from raw ingredients to a sealed, market-ready product involves sophisticated industrial processes, primarily focusing on precision filling and secure sealing. These steps are critical for product quality, safety, and efficiency.

Precision Filling Technologies

Following jam preparation, which often includes cooking and cooling, the product is typically held in a large hopper before the next critical step: the precise filling of containers. The selection of the appropriate filling machine is paramount and depends heavily on the jam’s viscosity, the presence and size of particulates (like fruit chunks), and the required production capacity.

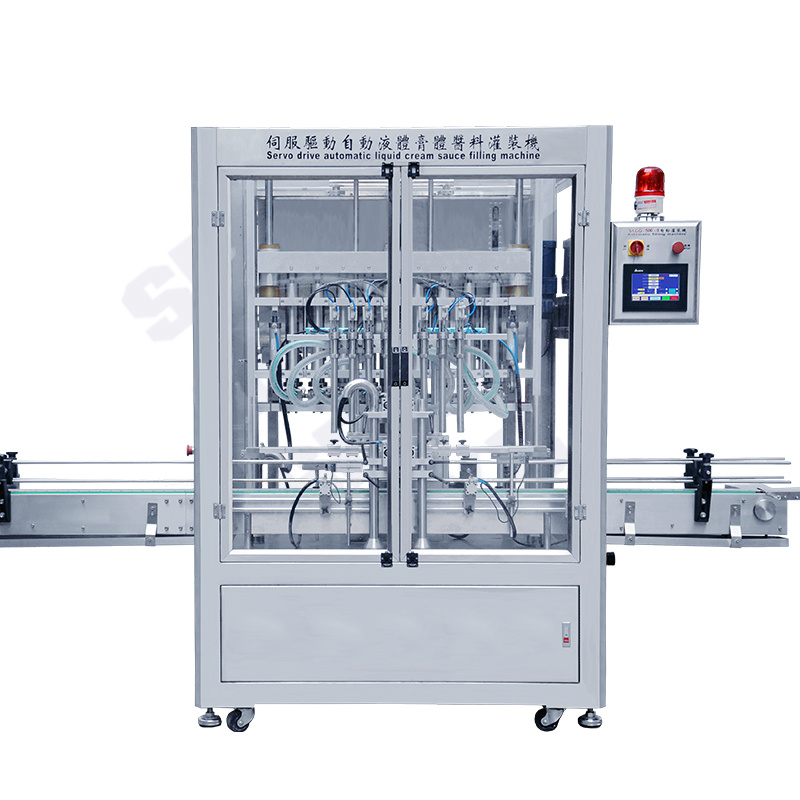

Piston Fillers: These machines are exceptionally well-suited for filling very viscous products and those containing large particulates, such as jams with whole fruit pieces, heavy sauces, or chunky salsas. Their working principle involves accurately pumping a predetermined amount of product into each container. Piston fillers are lauded for their high accuracy, often achieving precision up to +/- 0.25%, and their design minimizes product degradation, ensuring the integrity of delicate fruit chunks. This precision translates directly into cost savings by reducing product overfill.

|

| XBGG series automatic multi-head servo drive piston filling machine |

Volumetric Fillers: Volumetric filling machines are broadly designed to accurately dispense a measured volume of product into each container, ensuring consistent fill levels and significantly reducing product overfill, which translates to direct cost savings for manufacturers. It is important to note that piston fillers are a specific, highly precise type of volumetric filler, particularly effective with thick products.

Pump Fillers: While often encompassing piston and volumetric methods, dedicated pump filling systems are versatile and can handle a wide range of product consistencies. For jams with granules or specific textures, lobe pump filling methods are particularly efficient, ensuring high-precision operations and maintaining a uniform distribution of particulates within the jam. This ensures product consistency, which is vital for consumer satisfaction.

|

| XBTG series high-precision ceramic pump desktop paste liquid pneumatic filling machine |

After filling, containers move to the sealing stage, a critical step that secures the product and extends its shelf life.

Capping and Lidding: This involves securely placing and tightening lids or caps onto the filled jam containers. This mechanical sealing is the first line of defense against external contamination and helps to create a tight fit.

|

| XBKX-200 Three-four-rotation vacuum sealing and capping machine |

Induction Sealing: A highly advanced and increasingly common sealing method, induction sealing is a non-contact heating process. It utilizes electromagnetic induction to weld a foil laminate (known as an inner-seal) to the lip of jars and bottles. This process creates a hermetic, airtight seal that significantly improves product shelf life by preventing the ingress of air, moisture, and contaminants. Furthermore, induction seals provide a crucial tamper-evident feature, assuring consumers of product safety and integrity. Induction sealing machines are versatile, capable of sealing various container materials, including plastic, glass, and metal, though sealing with metal caps requires careful consideration due to heat transfer. The speed and efficiency of this process make it ideal for high-volume production lines.

|

| SF-2900D Water-cooled Automatic Electromagnetic Induction Aluminum Foil Sealer |

The Rise of Aseptic Filling

Aseptic filling represents a significant advancement in food packaging technology, particularly for products sensitive to heat.

Benefits for Heat-Sensitive Jams and Extended Shelf Life: Aseptic filling is an advanced technique that operates under highly sterile conditions to fill products into containers that are not pre-sterilized. This method is particularly advantageous for heat-sensitive products, as it maintains the product at room temperature, thereby preserving the jam’s original taste, texture, and nutritional value without the degradation that can occur with high-temperature hot filling. Aseptically filled products typically boast a significantly longer shelf life compared to those processed via traditional hot filling, reducing waste and expanding distribution possibilities.

Maintaining Product Integrity and Sterility: Aseptic systems are engineered to create and maintain a highly sterile environment throughout the filling process, minimizing the risk of product degradation and contamination. This is achieved through sophisticated features such as fully enclosed stainless steel sealing windows, Fan Filter Units (FFU) equipped with high-efficiency filters to maintain pure internal air, positive pressure environments, and high-pressure steam sterilization of fittings and caps prior to each filling cycle, often eliminating the need for chemicals. This meticulous approach ensures the highest standards of cleanliness and product integrity.

The sophistication of filling and sealing machinery directly correlates with product quality, safety, and operational efficiency. Investment in advanced Packaging Machine technology is therefore a critical competitive advantage for jam manufacturers. These machines are not merely operational tools; they are strategic assets. Precision fillers reduce overfill and minimize product degradation, directly impacting profitability. Advanced sealing mechanisms ensure extended shelf life and tamper-evidence, which are critical for consumer safety and trust. Aseptic filling preserves sensory attributes and extends shelf life for heat-sensitive products, opening new market segments and allowing manufacturers to differentiate their offerings. The emerging trend towards aseptic filling for jams, traditionally a hot-filled product, indicates a significant market shift towards higher quality preservation methods that prioritize sensory attributes and extended shelf life, even for products not typically considered “sensitive” in the same way as dairy products. This signals a premiumization trend in the jam market where consumers are increasingly willing to pay for products that retain their natural qualities.

Table 2: Industrial Jam Filling Technologies Overview

| Technology | Suitability (Jam Consistency/Particulates) | Key Advantages | Typical Applications |

| Piston Filler | Very viscous, large particulates (e.g., fruit pieces) | High accuracy (+/- 0.25%), low product degradation, reduced overfill, versatile | Jams with whole fruit pieces, heavy sauces, chunky salsas |

| Volumetric Filler | General volume dispensing, various viscosities | Consistent fill levels, significant cost savings (reduced overfill) | Standard fruit jams, jellies, marmalades |

| Pump Filler | Granular products, wide range of viscosities | Efficient, high-precision, maintains uniform distribution of particulates | Jams with seeds or small granules, sauces, purees |

| Aseptic Filler | Heat-sensitive products, sterile requirements | Preserves original taste/texture/nutrients, extended shelf life, enhanced hygiene, no chemical sterilization | Premium/natural jams, organic fruit spreads, products for extended distribution |

Ensuring the safety and integrity of jam products is paramount, necessitating strict adherence to a complex web of global food safety regulations and quality management systems.

Global Standards for Food Contact Materials

It is unequivocally crucial that all materials used in jam packaging are non-toxic and food-safe to prevent any contamination of the product. Adherence to stringent regulatory compliance is not merely a legal obligation but a fundamental requirement for market access, maintaining consumer trust, and ensuring public health.

FDA Regulations (United States): The U.S. Food and Drug Administration (FDA) plays a pivotal role in regulating Food Contact Materials (FCMs), encompassing a wide array of substances including plastics, paper, adhesives, dyes, and specialized coatings used in packaging. The FDA evaluates safety through four primary pathways: listing in Title 21 of the Code of Federal Regulations (21 CFR), classification as Generally Recognized as Safe (GRAS), Threshold of Regulation (TOR) exemptions, or approval via a Food Contact Notification (FCN). Manufacturers must demonstrate a “Reasonable Certainty of No Harm,” often requiring extensive testing to ensure harmful chemicals do not migrate from the packaging into the food. This process is dynamic, with the FDA performing post-market reassessments if new scientific evidence raises safety concerns, demanding continuous monitoring and meticulous documentation from manufacturers.

EU Regulations (European Union): The European Union has a robust framework for FCMs, notably Regulation 1935/2004, which applies broadly to all food contact materials (plastic, paper, glass, metal). This regulation mandates that materials must not be toxic, pose any harm to human health, or cause unacceptable changes in the food’s composition, taste, smell, or overall quality. For plastics, EU Regulation 10/2011 requires all ingredients to be reviewed against a “positive list” with specific migration and residual content limits. Compliance is often demonstrated through laboratory testing, including heavy metal testing, primary aromatic amine testing, and color fastness testing, culminating in a Declaration of Compliance (DoC).

Quality Management Systems in Jam Packaging

Beyond regulatory mandates, various globally recognized certifications provide frameworks for robust food safety management, often becoming de facto requirements for international trade.

HACCP Principles: Hazard Analysis and Critical Control Points (HACCP) is a globally recognized, systematic approach to food safety. It involves identifying, evaluating, and controlling biological, chemical, and physical hazards throughout the entire food production chain, from raw material procurement to consumption. The system is built upon seven core principles: conducting a hazard analysis, determining critical control points (CCPs), establishing critical limits, implementing monitoring procedures, defining corrective actions, establishing verification procedures, and maintaining thorough record-keeping and documentation. This systematic approach ensures that if a deviation occurs, it is detected, and appropriate steps are taken to reestablish control, preventing hazardous products from reaching the consumer.

BRCGS and FSSC 22000: The BRCGS Global Standard for Packaging Materials, developed by the British Retail Consortium, is a widely respected certification specifically for packaging manufacturers. It is often a mandatory requirement for suppliers operating in international markets like the U.S. and Europe, highlighting its critical role in global trade. FSSC 22000 is another globally recognized scheme that integrates the ISO 22000 standard with industry-specific requirements for food packaging manufacturers, focusing on systematic hazard management throughout the production process.

The increasing global harmonization and stringency of food safety standards, exemplified by certifications like BRCGS and FSSC 22000 becoming mandatory for international trade, drives an accelerated need for automated and traceable packaging solutions. Manual processes are inherently more prone to human error and inconsistency in meeting these exacting standards. This creates a compelling business case for investing in automated Packaging Machine lines, as such equipment, especially those with features like PLC control, smart sensors, and hygienic design, directly addresses this critical industry need. These machines not only enhance production efficiency but also serve as essential partners for manufacturers seeking to achieve and maintain global food safety certifications and expand their market reach.

Table 3: Key Global Food Packaging Regulations & Standards

| Standard/Regulation/System | Geographic Scope/Applicability | Core Requirement/Principle | Compliance Mechanism/Certification |

| FDA (United States) | US Market | Non-toxicity, “Reasonable Certainty of No Harm” for food contact substances | 21 CFR, GRAS, TOR, FCN pathways; Lab testing for chemical migration |

| EU Regulation 1935/2004 | EU Market (All FCMs) | Materials must not be toxic, harm human health, or alter food composition/sensory qualities | Lab testing & Declaration of Compliance (DoC) |

| EU Regulation 10/2011 (Plastics) | EU Market (Plastic FCMs) | All ingredients reviewed against “positive list” with specific migration limits | Lab testing & Declaration of Compliance (DoC) |

| HACCP Principles | Global (Food Safety Management) | Systematic identification, evaluation, and control of biological, chemical, and physical hazards (7 principles) | Implementation of 7 principles; Prerequisite programs; Record-keeping |

| BRCGS Global Standard for Packaging Materials | Global (Packaging Manufacturers) | Comprehensive quality management system for packaging materials | Third-party certification (often mandatory for international trade) |

| FSSC 22000 | Global (Food Safety System) | Systematic management of food safety hazards throughout production process (ISO 22000 + industry-specific requirements) | Third-party certification, compatible with ISO 9001/14001 |

VI. The Strategic Role of Secondary Packaging: Beyond the Primary Container

While primary packaging directly contains the jam, secondary packaging plays a crucial, often underestimated, role in ensuring the safe, efficient, and appealing distribution of products from manufacturers to end consumers.

Definition and Core Functions

Secondary packaging serves as the outermost layer of packaging for products, providing additional protection, convenience, and information. Its main purpose is not to hold the product directly—that is the role of primary packaging—but rather to safely and efficiently deliver large quantities of product to a retailer or end user. Removing the secondary packaging will not affect the product itself.

A key function of secondary packaging is to provide an extra layer of protection during transportation and handling, helping to prevent damage to the primary packaging and the product inside, thereby reducing the likelihood of breakage or spoilage. Furthermore, secondary packaging allows for grouping multiple primary packages, such as individual jam jars or jam containers, making it easier to handle and transport as a single unit. This facilitates bulk handling and distribution, streamlining logistics and reducing the risk of damage during shipping.

Enhancing Brand Presentation and Information Dissemination

Beyond its protective and logistical roles, secondary packaging is a powerful platform for branding and product information. It allows for the inclusion of graphics, branding elements, and product details, making the product more visually appealing and easily identifiable on store shelves. This layer can serve as the consumer’s first point of contact with the product, influencing purchasing decisions through its visual appeal and informative content.

Secondary packaging also provides additional space for communicating important information such as product instructions, usage guidelines, safety warnings, and regulatory compliance details, which is particularly important for certain food products. Some secondary packaging also includes features like tamper-evident seals or security measures to protect the product’s integrity and ensure it has not been tampered with before purchase.

Types of Secondary Packaging for Jams

For jams, secondary packaging can take various forms, each serving specific purposes:

Jam Boxes: Made from materials like cardboard, paperboard, or kraft paper, these are commonly used for individual jam jars or to create multi-packs, such as boxes for jam gift sets or sampler collections. They offer structural integrity and a printable surface for branding.

Gift Packaging and Luxury Boxes: For premium or children’s jams, secondary packaging can be designed as luxury boxes with additional elements like toys, stories, or vibrant colors. These packages enhance the excitement of the product and its use, offering additional gift value and stimulating a more whimsical interaction with the product’s content.

Special Designs: Secondary packaging can feature special designs for seasonal usage, such as holiday motifs or limited-edition artwork, increasing customer desire to acquire them. Descriptive graphics on the box can convincingly demonstrate the ingredients or flavor profile, making the product look more appealing. Furthermore, brands can use the inner layer or the

jam container bundle pack to incorporate designs that showcase the brand story through graphics, fostering a personal bond between the brand and the consumer.

Other types include trays, plastic bags, and bubble wrap, which primarily offer protection during transit and storage. The strategic design and selection of secondary packaging are crucial for overall product success and marketability.

VII. Emerging Trends Shaping the Future of Jam Packaging

The jam packaging industry is dynamic, driven by evolving consumer preferences, technological advancements, and a growing global consciousness regarding environmental impact. Several key trends are shaping its future.

Sustainability and Eco-Friendly Solutions

There is a rapidly growing consumer demand for jams packaged in sustainable and eco-friendly materials. This trend is influencing material choices and packaging design across the industry.

Glass and metal remain highly favored for their environmental credentials, being widely recyclable and environmentally friendly options.6 Many companies are actively switching to recycled PET plastic to be more eco-friendly. Beyond traditional materials, innovations include the development of biodegradable and compostable materials for flexible packaging, such as certain types of pouches, and even novel concepts like plantable seed paper labels that allow customers to grow wildflowers after use.

Furthermore, the industry is seeing a rise in bulk packaging and refill options, allowing consumers to refill their own jam containers and significantly reduce waste. Broader packaging innovations, such as Kraft Heinz’s 100% recyclable ketchup caps, Ecovative’s mushroom-based packaging (an alternative to polystyrene), and Coca-Cola’s plant-based plastic bottles, illustrate the industry’s commitment to reducing plastic waste and improving circularity. These developments signal a significant shift towards a greener future for food packaging.

Convenience and Portability

Modern lifestyles demand convenience, leading to a surge in demand for on-the-go and single-serve jam options. This trend is driving the popularity of flexible packaging formats.

Pouches, tubes, stick packs, mini jars, and squeeze bottles are increasingly common, offering portability and ease of use. Features like resealable caps and easy dispensing mechanisms are highly valued by consumers, minimizing mess and allowing for controlled portions. These formats are particularly popular for children’s products, travel, and jam sampler packs, catering to diverse consumer needs.

Premiumization and Customization

Consumers are increasingly willing to pay a premium for high-quality products that offer unique flavors and superior packaging. This trend is fostering a focus on artisanal, gourmet offerings and highly customized packaging solutions.

Brands are differentiating themselves through unique jar shapes, decorative lids, custom designs, and vibrant digital printed labels.12 There is also a strong emphasis on natural ingredients, organic options, and exotic flavor combinations, appealing to adventurous palates and health-conscious consumers. This focus on premiumization extends to the packaging itself, where materials like glass are often chosen to convey a sense of luxury and quality.

Automation and Smart Packaging

Automation is rapidly becoming the backbone of modern food manufacturing, offering significant advantages in speed, hygiene, consistency, and traceability. This is transforming packaging lines into highly efficient and reliable operations.

Robotic automation, in particular, is revolutionizing the food packaging industry by increasing efficiency and productivity, enhancing accuracy and consistency, providing flexibility and adaptability to different product types, and improving workplace safety by reducing manual labor in repetitive or hazardous tasks. These automated systems also contribute to cost savings by streamlining processes and minimizing waste.

The integration of advanced technologies like the Internet of Things (IoT) in packaging machines enables real-time monitoring and predictive maintenance, reducing downtime and optimizing operations. Smart labeling systems facilitate dynamic label printing and data coding (e.g., QR codes, batch numbers, expiry dates), crucial for traceability and consumer information. Furthermore, sustainable sealing technologies are being developed to work with eco-friendly materials like paper-based and compostable films. The integration of AI, IoT, and robotics is transforming packaging lines into intelligent, adaptive systems, which is crucial for future competitiveness in the global market. This shift from labor reduction to strategic enabler for quality, safety, and scalability underscores the indispensable role of advanced Packaging Machine solutions.

VIII. Conclusion: Preserving the Future of Jam

The world of jam packaging is a complex, dynamic ecosystem where scientific rigor meets market demands. This guide has explored the multifaceted role of packaging, extending far beyond mere containment to encompass critical functions of preservation, brand enhancement, and consumer trust. The selection of materials—from the timeless elegance of glass to the versatile utility of plastics, the robust protection of metals, and the innovative convenience of flexible pouches—involves intricate trade-offs between properties, cost, and environmental impact.

The precision and efficiency of industrial processes, particularly in filling and sealing, are paramount. Advanced technologies like piston fillers ensure accurate dispensing for viscous products, while induction sealing guarantees hermetic seals and tamper-evidence. The rising adoption of aseptic filling for jams signifies a strategic shift towards preserving delicate sensory attributes and extending shelf life, reflecting evolving consumer preferences for higher quality and natural products.

Navigating the stringent global regulatory landscape, including FDA and EU standards, alongside quality management systems like HACCP, BRCGS, and FSSC 22000, is non-negotiable for market access and maintaining brand integrity. These standards underscore the critical need for hygienic, consistent, and traceable packaging operations, which are increasingly facilitated by automated solutions. Furthermore, secondary packaging plays a vital role in logistics, protection, and brand communication, enhancing the overall consumer experience.

Looking ahead, the industry is being reshaped by powerful trends: an unwavering commitment to sustainability, a growing demand for convenience and portability, a drive towards premiumization and customization, and the transformative power of automation and smart technologies. For jam manufacturers, these trends necessitate strategic investment in advanced Packaging Machine solutions capable of handling diverse materials, ensuring precision and hygiene, and adapting to evolving market demands. The future of jam packaging lies in embracing these innovations to deliver products that are not only safe and delicious but also align with consumer values for quality, convenience, and environmental responsibility.

Frequently Asked Questions (FAQ) about Jam Packaging

1. What is jam packing?

Answer: "Jam packing" refers to the process of filling containers with jam. In a broader sense, "jam-packing" is an informal term meaning to fill something to its maximum capacity. In the context of food packaging, it involves efficiently filling containers to ensure optimal use of space and minimize air exposure, which helps in preserving the product's quality.

2. What is the best packaging for jam?

Answer: The optimal jam packaging depends on factors like product type, target market, and cost considerations. Common packaging options include:

● Glass Jars: Ideal for premium or artisanal jams, offering excellent preservation and a classic appearance.

● Plastic Containers: Cost-effective and lightweight, suitable for mass-market products.

● Flexible Pouches: Convenient for on-the-go consumption, often used for single-serving portions.

● Buckets: Used for bulk quantities, catering to restaurants or large-scale consumers.

● Blister Packs: Perfect for portion control, commonly used in foodservice settings.

Each packaging type offers distinct advantages, and the choice should align with the brand's positioning and consumer preferences.

lintyco.com

3. What is the primary packaging of jam?

Answer: Primary packaging is the material that directly contacts the jam and holds it for sale or distribution. For jams, this typically includes:

● Glass Jars: Provide a premium feel and excellent preservation qualities.

● Plastic Containers: Lightweight and cost-effective, suitable for larger volumes.

● Flexible Pouches: Modern and convenient, often used for single servings.

● Buckets: Used for bulk quantities, catering to institutional needs.

The choice of primary packaging affects the product's shelf life, consumer perception, and environmental impact.

4. What are the main functions of jam packaging?

Answer: The main functions of jam packaging are to protect the product from spoilage factors such as moisture, oxygen, UV light, and microorganisms, extend shelf life, preserve sensory attributes (flavor, aroma, color, texture), and enhance the product's brand appeal through aesthetic design.

5. What materials are commonly used for jam packaging?

Answer: Common materials used for jam packaging include glass jars, plastic containers (such as PET, PP, HDPE), metal cans, and flexible packaging solutions (such as pouches, tubes, and stick packs). Each material offers distinct advantages and disadvantages regarding preservation, cost, and consumer appeal.

6. How does glass packaging preserve jam quality?

Answer: Glass is chemically inert, preventing reactions with acidic contents like jam, and is impermeable to gases and particles. This helps preserve the jam’s flavor, aroma, color, and texture. Glass is also transparent, allowing consumers to see the product, enhancing its appeal.

7. How does aseptic filling benefit jam packaging?

Answer: Aseptic filling is a technique that preserves the jam’s original taste, texture, and nutrients by filling it into containers under sterile conditions without pre-sterilizing the packaging. This extends the shelf life of the product without the need for high-temperature filling, making it ideal for heat-sensitive jams.

8. What is induction sealing, and why is it important?

Answer: Induction sealing is a non-contact heating process that creates an airtight seal by welding a foil laminate to the container lip. It is crucial for enhancing product shelf life, preventing contamination, and providing a tamper-evident feature that assures consumers of product safety.

9. How do jam packaging materials impact environmental sustainability?

Answer: Glass and metal containers are highly recyclable and have eco-friendly profiles. Additionally, advancements in biodegradable and compostable flexible packaging are making waves in the industry. There is also an increasing trend toward using recycled PET plastic to reduce environmental impact.

10. What role does secondary packaging play in jam distribution?

Answer: Secondary packaging protects primary packaging during transportation, reduces the risk of breakage, and aids in efficient logistics. It also provides a space for branding, product information, and promotional content, helping products stand out on retail shelves.

| References: | |

| 1. | Standards of Identity for Jams and Preserves ——Retrieved from:FDA (U.S. Food and Drug Administration) |

| 2. | Benefits of Glass Packaging ——Retrieved from:The Glass Packaging Institute (GPI) |

| 3. | PMMI (The Association for Packaging and Processing Technologies) |

| 4. | Journal of Food Science / Packaging Technology and Science |

| 5. | Scientific Opinions on Food Contact Materials ——Retrieved from:European Food Safety Authority (EFSA) |

Comments