Sauce packaging is critical for food manufacturers who need to protect and preserve their products from production to table. Proper sauce packaging keeps products safe, extends shelf life, and supports branding and customer appeal. Whether you produce ketchup, hot sauce, salad dressing, or specialty condiments, the right packaging ensures that your sauces maintain flavor, texture, and quality during storage and transport. This guide covers everything from package design to filling lines and will help you improve efficiency and product quality in your sauce packaging operation.

Key Characteristics of Sauce Packaging

Sauces present unique packaging challenges due to their viscosity, shelf-life requirements, and hygiene concerns. Most sauces (ketchup, tomato sauce, mustard, etc.) have a thick, pasty consistency that demands robust filling machines. High viscosity means filling lines often use piston or pump fillers that can handle sticky, semi-solid products. By contrast, thin, runny sauces (like vinegars or light dressings) may use gravity or volumetric fillers.

Shelf life is another critical factor. Many sauces are shelf-stable (often pasteurized or acidified), so containers must provide good barrier properties. Rigid containers like cans or airtight jars prevent spoilage and significantly extend shelf life. For example, steel cans provide strong protection against air and light, giving sauces a long shelf life during export. Similarly, high-barrier flexible pouches and glass jars block oxygen and moisture, preserving freshness.

Hygiene and safety are paramount in sauce packaging. Regulations require food-grade materials and sanitary design. Fully automatic filling lines use stainless steel contact parts and clean-in-place (CIP) systems to avoid contamination. As one industry expert notes, “food production has extremely high hygiene requirements. [Automatic sauce packaging machines] use materials and designs that meet food-grade standards… and automatic cleaning… ensures the hygienic status of the equipment”. Careful sanitation of equipment and containers prevents microbial growth and keeps your sauces safe for consumers.

● Viscosity: Sauce viscosity varies widely (thin dressings vs. thick paste). High-viscosity sauces need strong, precise filling mechanisms.

● Shelf Life: Packaging should be airtight and light-blocking to extend shelf life. Durable materials like glass and metal are often used.

● Hygiene: Equipment and containers must meet strict sanitary standards. Automatic cleaning (CIP) and sealed filling help prevent contamination.

Common Packaging Shapes and Materials for Sauces

Sauces are packaged in a variety of formats to suit different markets and uses. The choice of shape and material depends on sauce consistency, portion size, and branding. Common sauce packaging formats include:

● Bottles: Rigid bottles (glass or PET plastic) are widely used. Glass bottles give a premium look and excellent barrier protection, while PET bottles are lightweight and shatter-resistant. Ketchup, mustard, barbecue sauces and salad dressings often come in classic glass or PET bottles. Squeeze-style plastic bottles (with a nozzle cap) are especially popular for easy dispensing.

● Jars: Glass jars (with screw caps) are ideal for thick, specialty sauces (like gourmet hot sauces or chutneys). The rigid structure provides maximum protection: as Allpack notes, “glass jar is the most protective type of sauce packaging… its strong, durable material prevents any interaction between the sauce and dust, moisture or air”. Reusable jars also appeal to consumers and can reinforce brand loyalty.

● Flexible Pouches: Stand-up pouches and spouted pouches are increasingly common. Spouted pouches (with a screw cap) are popular for ketchup, hot sauce and baby food because they are lightweight and portable. They take up less space on shelves and are convenient for on-the-go use. Flat sachets (four-side seal packets) are another pouch type used for single-serve condiments (often in foodservice). Flexible materials (multilayer films or laminated plastic/foil) offer good barrier and reduce weight.

● Sachets/Packets: Small sachets (like those for ketchup or soy sauce at fast-food outlets) use heat-sealed foil or plastic material for one-time use. These are simple to fill in large quantities and provide precise single servings.

● Cans (Metal): Metal cans (often tin-plated steel) are used for large-batch, shelf-stable sauces (tomato sauce, vegetables in sauce, etc.). High-strength cans protect against spoilage and allow sauces to be shipped globally.

● Tubs and Tubs: Plastic tubs (large HDPE or PP containers) are used for foodservice or bulk retail. They hold large volumes (family or catering sizes) and are easy to open and reseal.

● Cups and Jars: Smaller plastic cups (with foil lids) are used for single-serve sides. Squeeze tubes (like toothpaste tubes) are rare but used for certain gourmet sauces.

Each package type has benefits. Bottles and jars enable premium presentation and reuse, pouches cut shipping weight and cost, and cans maximize shelf life. Choose a shape and material based on your sauce formula and customer needs. For example, Harrison’s Sauces notes: “Bottles [are] ideal for thicker sauces… Pouches [for] single-use portions… Cans [for] sauces with a longer shelf life… Jars [for] specialty or gourmet sauces”.

The Sauce Packaging Process: Filling, Sealing & Labeling

Packaging a sauce typically involves three main steps after cooking/formulation:

● Filling: Containers (bottles, pouches, jars) are automatically conveyed to the filling station. Measured amounts of sauce are dispensed into each container via nozzles or fillers. Modern filling machines (piston, pump, or volumetric fillers) accurately dose the right weight or volume. For example, “the first step… is to fill them with sauce… done by filling the sachets or glass bottle with the help of nozzles. These nozzles are operated automatically”. Precise filling minimizes waste and ensures consistency batch-to-batch.

● Sealing: Once filled, the containers are hermetically sealed to keep the sauce fresh. Bottles may get screw caps or capping wheels, pouches are heat-sealed, and cans are sealed via seamers. As one guide explains, after filling, impulse sealers or heat guns “apply a high temperature to seal [the sauces] off”. Proper sealing prevents leaks and oxygen ingress, extending shelf life. In automated lines, capping and sealing can be integrated right after filling to save time.

● Printing and Labeling: The final step is labeling the package with product information and branding. Labelers apply stickers or shrink sleeves to bottles/jars, and pouches may be printed on-roll before filling. Attractive design is key – “the aesthetic of the product packaging would be the key feature to attract customers”. On-label information (ingredients, nutrition, expiry dates) is also applied either by labels or direct printing. Modern lines often include automatic label applicators that handle high speeds while ensuring alignment and accuracy.

These steps (filling, sealing, labeling) can be performed manually for very small operations or fully automated in a continuous line. Automation reduces human error and increases throughput (discussed below). In small batches, semi-automatic fillers and sealers might be used, but commercial scale sauce packaging almost always employs automatic machinery to meet demand efficiently.

Automatic Sauce Filling Lines: Machine Types

As production scales up, food companies use automatic filling lines equipped with specialized machines. These lines handle sauce with minimal human intervention, improving speed and consistency. Key types of filling machines used in sauce packaging include:

● Piston Filling Machines: Piston fillers are common for thick sauces. They work by drawing sauce into a cylinder and then pushing it into the container in a measured stroke. Piston fillers offer excellent accuracy with high-viscosity products. According to industry sources, “Piston filling systems handle various product viscosities with precision… Thick sauces or creamy lotions smoothly filling without a hiccup”. Piston fillers can be semi- or fully-automatic and may serve rotary in-line cappers. They are ideal for ketchup, mayonnaise, peanut butter, and other heavy sauces.

● Gravity Filling Machines: Gravity fillers rely on natural flow from a tank. Bottles pass under valves, and liquid fills by gravity. These are best for thin, low-viscosity sauces (similar to juicier dressings). Gravity machines are simple, high-speed, and cost-effective. As noted, “Gravity fillers… are perfect for watery substances like juices… small-scale operators… lean towards these low-maintenance, budget-friendly allies”. However, gravity fillers are less suited for chunky or very thick sauces, since higher viscosity hinders flow.

● Pump/Peristaltic Filling Machines: Pump fillers (including peristaltic or rotary lobe pumps) use positive-displacement pumps to move sauce into containers. They are very gentle (no shear stress), making them suitable for sauces with particles or foaming issues. Pump fillers can handle low to high viscosity depending on pump design. They provide good control and can fill any container shape. The downside can be slower speed and more frequent maintenance of pump parts. Pump fillers are often used for hot sauces, dressings with seeds, or paste products where gentle handling is needed.

● Rotary/Indexing Filling Systems: Rotary fillers consist of a circular turret with multiple filling heads. Containers are indexed around a turntable and simultaneously filled on multiple stations, then capped and labeled further along. These machines achieve very high throughput and are common in large sauce factories. A rotary system might use piston or pump fill heads arranged around the carousel. For example, a 12-nozzle rotary sauce line can fill dozens of bottles per minute. While extremely fast and efficient, rotary systems require significant investment and floor space.

● Cup (Volumetric) Fillers: These measure sauce by volume using calibrated cups or plungers. They are often used for products of moderate viscosity and are faster than piston for thinner fluids. However, their accuracy can vary with product thickness, and they are generally limited to certain container sizes.

● Net Weigh Fillers (for sauce): Though less common for sauces due to slower speed, net weigh scales can fill large or batch amounts by weight. They ensure precise net weights but are used mostly where accuracy is paramount (e.g. high-value sauces) rather than high speed.

Each machine type has its place. For most hot or tomato sauces, piston or pump fillers are preferred to cope with thickness. For very thin sauces or dressings, gravity or cup fillers work well. Multipurpose lines often combine different filling methods (e.g. a piston filler on a rotary platform). The right choice depends on production volume, sauce formula, and budget.

|

| Automatic Sauce Filling Line |

Advantages of Automated Sauce Packaging Solutions

Upgrading to an automatic filling and packaging line offers many advantages over manual methods:

● Higher Efficiency and Output: Automated lines fill, cap, and label bottles or pouches continuously at high speeds. A modern line can handle hundreds of units per minute. This dramatically increases production output for large batches. As one source notes, fully automatic operations “greatly improve packaging efficiency… can complete a large number of packaging tasks in a short time”.

● Precise Filling and Reduced Waste: Machines ensure each container gets the exact set volume or weight of sauce. Precision controls (servo systems, sensors, or gravimetric feeders) maintain consistency. This reduces giveaways and scrap. Precision “accurately control[s] the filling volume of each bottle of sauce to ensure product consistency… High-precision filling operation reduces the waste of sauce”.

● Enhanced Hygiene and Safety: Automatic equipment uses sanitary designs and food-grade materials. They often include CIP cleaning so lines can be quickly sterilized between runs. As mentioned above, such machines “use materials and designs that meet food-grade standards… automatic cleaning… ensures the hygienic status of the equipment”. This helps comply with food safety regulations and minimizes contamination risk.

● Consistent Quality: Automation eliminates human variability. Each label is placed perfectly, each seal is applied correctly, and visual inspection systems can reject underfilled or misaligned products. The result is a uniform, professional finished product every time.

● Flexibility and Integration: Modern filling lines can switch between containers or products with minimal downtime. Some systems use adjustable parts to handle bottles, jars, cans or pouches on the same line. For example, a modular line may run glass jars one shift and plastic bottles the next. Automated capping and labeling modules also streamline changeovers.

● Lower Labor Costs: Fewer operators are needed once machines are running. Staff can shift from manual filling tasks to supervisory or quality roles. Over time, reduced labor and higher yields offset the investment in equipment.

● Data and Control: Many lines offer data collection and monitoring (e.g. counting filled units, logging fill volumes, alerting for errors). This improves traceability and process optimization.

In summary, automated sauce packaging lines boost efficiency, precision, and hygiene, giving manufacturers a competitive edge. They are especially valuable for scaling up production or meeting strict quality standards.

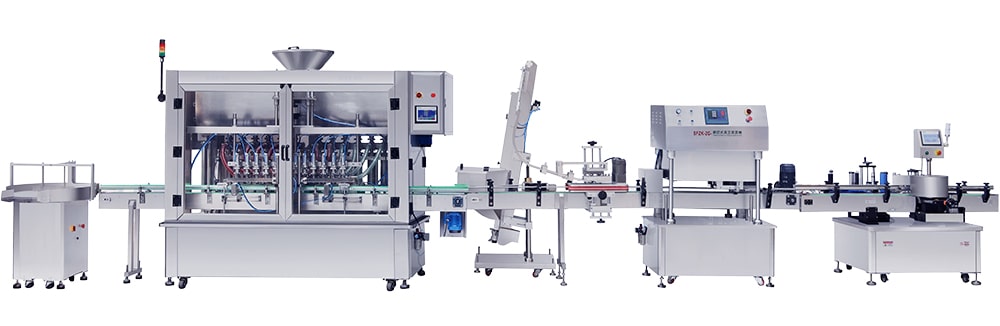

|

| Automatic sauce filling production line (bottle sorting machine-12 piston filling-capping machine-double-sided labeling machine) |

Comparison of Sauce Filling Machine Types

Below is a summary comparison of key filling machine types used in sauce packaging, with their pros, cons, and typical applications:

| Filling Machine Type | Pros | Cons | Common Applications |

|---|---|---|---|

| Piston Filler | Excellent for high-viscosity sauces; very precise and repeatable filling. Handles chunky particulates. | More complex and costly; slower cycle for thin liquids. Requires skill to maintain. | Thick sauces (ketchup, mayonnaise, peanut butter, pastes). |

| Gravity Filler | Simple and cost-effective for low-viscosity liquids. Fast throughput with minimal maintenance. | Not suitable for thick or foamy products; less control of fill level if viscosity varies. | Thin sauces, vinegars, dressings, beverages. |

| Rotary (Multi-head) Filler | Extremely high speed (many heads fill simultaneously); easily integrates with capping/labeling. Continuous flow means large output. | High capital cost and larger footprint. Complex setup and maintenance. | High-volume sauce bottling plants and mass-market condiments. |

| Pump/Peristaltic Filler | Gentle on product; suitable for abrasive or particle-containing sauces. Fully adjustable fill volume; handles thin to thick sauces with correct pump. | More moving parts requiring maintenance. Potential slower speed for very viscous products. | Chunky sauces, salsas, hot sauces, sauces with seeds or bits. |

| Volumetric Cup (Overflow) Filler | Good for moderate viscosity; provides consistent fill levels. Can operate quickly. | Limited viscosity range; less accurate for very thick products. Not ideal for opaque containers (no visible fill line). | Salad dressings, juices, beverages (see-through container filling). |

This table highlights how each filling machine has strengths and weaknesses. For example, a piston filling machine is unmatched for viscous products, but if your sauce is thin, a gravity or overflow filler may be faster and cheaper. A rotary filler line provides maximum output if demand is very high. Choose the machine type that aligns with your sauce properties and production volume.

|

| XBGZ-500-12 Fully automatic 12-head servo paste filling/capping/sealing/labeling production line |

SFXB’s Experience in Sauce Packaging

Guangzhou SFXB Special Equipment Co., Ltd. (XueBa) is a seasoned manufacturer of automated filling lines and packaging machines for sauces and condiments. With ISO certification and nearly 25 years of experience, SFXB (also known as XueBa) has developed “intelligent automatic filling production lines” for a wide range of liquid products. The company’s portfolio includes complete production lines with automatic bottle unscramblers, multi-head filling machines, capping, sealing, and labeling units.

SFXB highlights its capability to handle condiments and sauces of all kinds, offering solutions for glass or plastic bottles, pouches, cans, and more. In fact, our machines have been used for tomato sauce, chili sauce, soy sauce, and other food-grade products by many well-known enterprises globally. SFXB emphasizes customization: each sauce line can be tailored (with piston fillers, servo pumps, rotary platforms, etc.) to meet specific viscosity and speed requirements.

Some notable aspects of SFXB’s offering include:

● Full automation from filling to labeling, improving hygiene and throughput.

● A range of filling machines (piston, ceramic pump, servo-driven, etc.) suited to various sauce types.

● Extensive R&D capability and experience since 2000, enabling them to solve unique packaging challenges.

● Support for international standards and export markets, having become “the designated product supplier of many well-known enterprises” in sauces and beverages.

By leveraging SFXB’s expertise, manufacturers can tap into sophisticated sauce packaging equipment that enhances production efficiency and consistency.

Conclusion and Next Steps

In summary, sauce packaging is a specialized field that combines material science, machinery, and food safety. The right packaging shape (bottle, pouch, jar, can, etc.) must match your sauce’s viscosity, shelf-life needs, and consumer expectations. Modern sauce filling lines employ advanced filling machines (piston, gravity, rotary, pumps) to achieve high efficiency and precision. Automated lines boost throughput, ensure consistent fill levels, and maintain strict hygiene standards.

When selecting equipment, compare the pros and cons of each filling technology as shown above, and consider a custom solution if your product has special requirements. Companies like SFXB bring decades of experience in designing complete sauce packaging lines. They can provide everything from compact single machines to multi-station production lines, fully tailored to your sauce’s properties and production goals.

Ready to upgrade your sauce packaging line? Contact us today to discuss your requirements. Our experts can recommend the ideal filling machines and automated line setup for your product. Request a quote or consultation to see how custom sauce packaging solutions can streamline your operation and enhance product quality.

● Boost Efficiency: Automate your filling, sealing, and labeling to increase throughput.

● Ensure Quality: Maintain precise fills and hygienic conditions with top-grade equipment.

● Customized Solutions: We can tailor your line to any bottle, pouch, or jar size.

Secure your competitive advantage in sauce production with a state-of-the-art automatic filling line. Contact SFXB now to learn more or request a quote on custom sauce packaging solutions – our team is ready to help you succeed!

| References: | |

| 1. | FAO – Manual on Food Packaging |

| 2. | Haque et al., “Degradation Behavior of Multilayer Packaging Films in the Presence of a Highly Acidic Sauce,” Journal of Food Engineering (2023) –Retrieved from: ScienceDirect |

| 3. | “Packaging Design for Recycling Guide” –Retrieved from: World Packaging Organization |

| 4. | Food Packaging Forum |

Comments