Industrial labeling machinery encompasses the equipment and systems used to automatically apply labels to products and packages. In modern manufacturing, accurate and consistent labeling is crucial for branding, compliance, and traceability. Automated labeling machines attach or print labels onto products (such as bottles, jars, cartons, or pallets) with minimal human intervention. These machines are vital across industries – from food and beverage to pharmaceuticals and electronics – because almost all consumer goods require clear labels for identification, barcodes, ingredients, or branding. A range of specialized label applicator machines (also called label printer applicators) handle printing and dispensing labels robotically. By using modern labeling machinery, manufacturers achieve higher throughput, better accuracy, and compliance with regulations (e.g. batch codes, expiry dates) that manual methods cannot match.

Labeling systems can be categorized by their automation level (manual, semi-automatic, or fully automatic), method of application (pressure-sensitive “peel-and-stick” labels vs. shrink sleeve), and container shape (round bottles, square jars, flat cartons, etc.). For instance, bottle labeling machines are designed to wrap or apply labels to cylindrical bottles, while jar labeling machines may handle wider bodies and flat sides. Some machines use tamp-blow or wipe-on techniques to affix pressure-sensitive labels, whereas shrink sleeve labeling machines dispense plastic sleeves that are later shrunk with heat for 360° coverage. Newer “print-and-apply” labelers combine an integrated printer and applicator to print each label on demand and immediately apply it to a moving product. Each machine type is engineered for certain volumes and product shapes: semi-automatic labeling machines require an operator to load or trigger labels (ideal for small batches), whereas automatic labeling machines run inline on a conveyor and label at high speed with minimal human input. Choosing the right machine depends on production needs, label type, and container geometry.

Classification by Automation Level

Labeling machines range from manual units to semi-automatic and fully automatic systems. Manual labeling machines are simple benchtop or hand-fed devices used in very low-volume or craft settings. An operator typically places the product and wraps or presses the label by hand; such machines improve consistency slightly over hand-labeling but still require full human effort. In contrast, a semi-automatic labeling machine automates much of the process but still involves the operator. For example, the worker may place bottles on a conveyor or manually feed labels, then trigger the machine; after that, the machine dispenses, cuts, and applies the label, and the operator removes the finished product. This setup increases speed and consistency over purely manual work and is cost-effective for moderate volumes. However, it relies on the operator to load or align items correctly.

Fully automatic labeling machines are the most advanced. They integrate with conveyor lines and require virtually no human intervention during operation. Products (e.g. bottles or cans) are fed continuously from one end and exit at the other fully labeled. Sensors detect each item and precisely stop or slow the line momentarily while a label is applied. These machines use mechanical applicators (e.g. pneumatic tampers or air jets) to attach labels on the fly, achieving high precision. Automatic systems handle high-speed, large-scale production – hundreds to thousands of items per minute – with consistent placement and minimal error. They are ideal for industries like beverage bottling or pharmaceuticals where accuracy and throughput are critical. In general, manual and semi-automatic labeling machines are best for lower volumes or specialty production runs, whereas automatic labelers are preferred for mass production.

SF-3030 Automatic round bottle labeling machine

Types of Labeling Machines by Product and Method

Labeling machinery is also tailored to the product shape and label type. Round bottle labeling machines wrap labels around cylindrical containers (e.g. soda bottles, condiment jars). They often use rotating belts or turntables to spin the bottle while the label is applied, ensuring a smooth wrap. Jar labeling machines are similar but may accommodate wider or differently shaped bodies. For flat or square products (like cartons, boxes, or tins), wipe-on applicators with brushes or rollers press labels onto one or more flat surfaces. Dual-sided or multi-sided labelers handle cases and cartons, applying labels to front and back with synchronized applicators. Custom machines exist for tubes, cans, vials, and odd shapes – for example, vial labeling systems apply small labels to medical vials using high-precision wrap-around methods.

Several application methods are used:

- Pressure-sensitive (peel-and-stick) labeling machines apply pre-printed self-adhesive labels. The label roll is peeled from its liner and attached to the product by a label applicator (pneumatic cylinder or blow nozzle). These are very common due to their speed and simplicity.

- Shrink sleeve labeling machines (or shrink label machines) use plastic sleeve labels (PVC, PET, etc.) that slide over the container. After application, the package passes through a heat tunnel and the sleeve shrinks to conform tightly around it. This gives 360° coverage (maximizing branding space) and tamper-evident seals. It is popular for beverages, cosmetics, and products needing full-surface graphics.

- Inflatable or stretch sleeve labelers use elastic labels stretched onto containers (less common than heat shrink).

- Inkjet or print-on-container systems directly print data or graphics onto packaging, sometimes combined with an applicator for adhesive labels (known as print-and-apply).

For example, in a water bottling plant, a water bottle label printing machine might consist of an inkjet printer that first prints variable information (batch codes, QR codes, etc.) onto a roll of labels, and then an automatic applicator that wraps those labels onto moving bottles. Similarly, label applicator machines (also called label printer applicators) often combine a mini printer and dispenser to print and apply labels on demand.

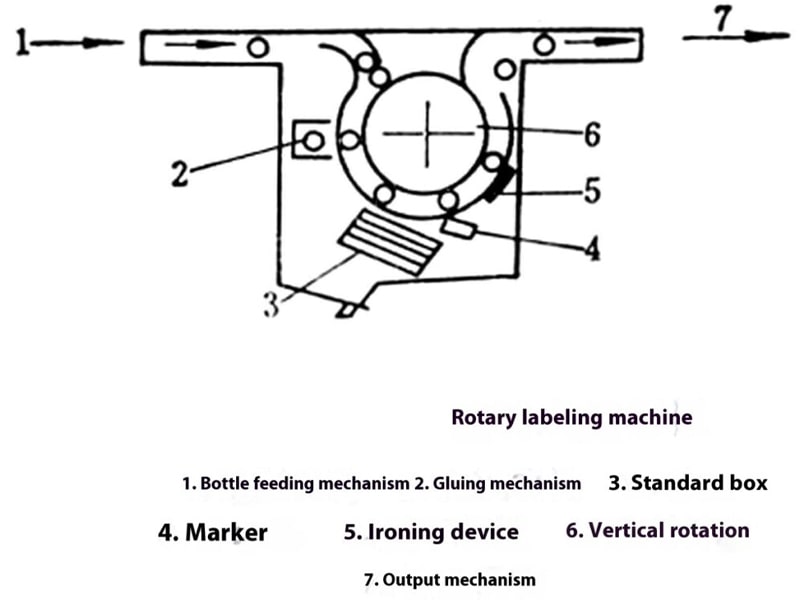

Below is an example of a gantry labeling machine, a common design for cylindrical containers: it uses rollers to carry the label, applies glue, and brushes the label onto a passing bottle. Another type, the rotary labeling machine, holds bottles on a rotating carousel (see image below) so each bottle can be labeled on multiple sides in sequence. Each labeling method is engineered for specific speeds and label types.

Figure: Diagram of a gantry labeling machine with rollers and brushes. Such machines are often used to wrap labels around cylindrical bottles.

Key Components and Operation

Modern labeling machines consist of several main components: label dispensers/printers, applicators, conveyance, and controls. First, labels are printed or dispensed from rolls or printers. In many systems, labels are pre-printed (often using thermal transfer or inkjet printers) onto paper or film with pressure-sensitive adhesive on the back. (Some labelers use direct thermal or laser printing built-in to create on-demand barcodes and variable data.) The label is held temporarily on an applicator pad until attachment.

Next, the label applicator delivers the label to the product. Common applicator methods include:

- Tamp-blow: A pneumatic cylinder (“tamp”) pushes the label pad against the container, then withdraws as a burst of air (blow) carries the label onto the surface.

- Blow-on (air-blow): The machine positions a label in front of the container and fires a short burst of compressed air, projecting the label from the applicator pad onto the product surface without contact.

- Wipe-on: A roller or brush physically wipes the adhesive label onto the container, often used for bottle labelers

These methods are described in packaging equipment design references. For example, in a tamp-blow system, a cylinder extends out touching the adhesive side of the label to a bottle; it then retracts and an air nozzle propels the label onto the bottle’s wall. The exact technique depends on the container material (glass vs. plastic), shape, and speed.

Sensors and controls synchronize the operation: photoelectric sensors detect when a bottle arrives, triggering the applicator at the correct moment. Labeling machines also include conveyors or turntables to position each item. For large production lines, vision systems and registration controls ensure the label is applied at the right angle and location.

Print & Apply Labelers

Some labeling machines integrate printing and application in one unit. These print-and-apply labelers receive a roll of blank label stock, print the desired information (text, barcode, graphics) on the spot, and then immediately apply it to the moving product. As products advance on the conveyor, each one pauses briefly in front of the applicator. The machine prints the next label, peels it off the liner, and attaches it – all while the product is still in the machine. This eliminates separate pre-printing and reduces inventory of pre-printed labels. Print-and-apply systems are highly efficient for just-in-time operations and for encoding batch data or serial numbers on each product. By combining functions, they reduce material waste and human error.

Benefits of Automated Labeling

Modern labeling machinery offers many advantages over manual or outdated methods. Key benefits include:

High Speed and Throughput: Automatic labeling machines can process hundreds of items per minute. For example, a high-performance round-bottle labeler may reach 200+ bottles/min. This unmatched speed keeps production moving and meets large order demands.

- Improved Accuracy and Consistency: Machines apply each label at the exact same position and tension, eliminating wrinkles, misalignment, or uneven spacing. Precise label placement is crucial for barcodes and branding consistency. Automated systems also ensure the correct label is placed on each product type. By using sensors and registration, error rates are far lower than hand-labeling.

- Labor and Cost Efficiency: Once set up, automatic machines require little supervision. This cuts labor costs and frees staff for other tasks. Even semi-automatic labelers greatly reduce operator fatigue and repetitive strain compared to hand labeling. Over time, the investment in machinery pays off through higher productivity and less waste.

- Versatility and Flexibility: Many machines can be quickly adjusted or programmed for different label sizes, shapes, or products. For example, quick-change platforms or reconfigurable applicator heads let manufacturers switch between labeling tall bottles one day and short jars the next with minimal downtime. Software-controlled printing allows on-the-fly design changes.

- Full-Coverage Branding (Shrink Sleeves): Shrink sleeve labelers provide 360° product coverage, enabling full-body graphics and tamper-evident seals. This maximizes brand visibility. As noted by packaging experts, shrink sleeves offer “superior branding opportunities” because they allow more creative and comprehensive labeling across the entire container.

- Durability and Protection: Labels applied by machines, especially shrink sleeves, are more durable. Shrink sleeves are resistant to moisture, abrasion, and chemicals. This ensures important info (nutrition facts, safety warnings) stays legible through shipping and storage. The secure adhesion prevents peeling and protects the label even under harsh conditions.

- Compliance and Traceability: Automated labelers can print and apply serialization (barcodes, QR codes, RFID tags) directly to products. This is vital in regulated industries like pharmaceuticals or food, where tracking each unit is required. For instance, RFID label printers embed chips and encode data into each label. Print-and-apply labelers can also add batch numbers or expiry dates in real-time, ensuring up-to-date compliance on every product.

Each of these benefits helps manufacturers meet quality standards and satisfy market demands. In fact, integrating print-and-apply systems “enhance efficiency and reduce the risk of human error and labor costs,” making them ideal for high-volume lines. Companies can thus achieve better productivity, fewer recalls, and stronger brand presentation by investing in advanced labeling machinery.

Industry Applications

Labeling machines are ubiquitous in packaging lines across sectors. Key applications include:

- Food & Beverage: Perhaps the most common use. Water bottling, soda, beer, sauces, and condiments rely on high-speed bottle labeling machines. For example, water treatment lines incorporate water bottle label printing machines to quickly add custom labels on 3–5 gallon jugs. Dairy products, canned goods, and edible oils also use wrap-around and front/back labelers to apply ingredient labels and branding.

- Pharmaceuticals: Medicines, vials, syringes, and health products require exacting label placement for safety (dosage instructions, lot codes). Vial and ampoule labeling systems are highly specialized to handle small glass containers. These machines often include vision inspection to verify label readability. Serialization labelers (case pallet aggregation) are used extensively for pharmaceuticals, enabling tracking and anti-counterfeiting.

- Cosmetics & Personal Care: Products like lotion bottles, creams in jars, or tubes use labeling machines to affix attractive graphic labels. Shrink sleeve labelers are popular for full-wrap designs on water bottles, sunscreens, or beverage bottles. Dual-sided labelers apply both front and back labels (e.g. for shampoo or detergent bottles) simultaneously to speed up high-demand lines.

- Industrial & Chemical: Containers for chemicals, oils, and lubricants use durable labeling solutions. These machines often apply larger, tough labels (sometimes foil or synthetic stock) that can resist solvents. Tanker trucks and large drums can even be labeled with specialized applicators.

- Electronics & Automotive: Products like batteries, cables, or electronic components are labeled for identification. Print-and-apply labelers are common for shipping labels and asset tags. RFID labeling systems are increasingly used for tracking parts in automated warehouses.

- Logistics & e-Commerce: While not “products” in the consumer sense, labeling machines also serve in shipping and warehousing. Case labelers quickly apply shipping labels or box contents labels, and pallet labelers print identification for entire pallets.

In each case, the type of labeling machine and label material is chosen to match product requirements (size, material, throughput). As the IQS industry guide notes, labeling machinery “serves a variety of industries” from food/beverage to home supplies, and can produce anything from basic barcodes to intricate logos. Modern factories often have multiple labeling stations — for example, one labeler for the main product label and another for safety or content labels — all coordinated by central control systems.

Choosing the Right Labeling Solution

Selecting an industrial labeling machine depends on several factors:

- Production Speed and Volume: Estimate the maximum units per minute or hour. Low-volume or startup lines might use manual or semi-auto labelers, while high-volume plants require automatic inline machines. Check the machine’s stated speed (e.g. 50, 100, 300 bottles/minute) against your needs.

- Container Type and Layout: Consider shape (round, oval, rectangular), size range, and surface (bumpy vs. flat). Some machines are modular and can be adjusted for various diameters; others are fixed. For example, round bottle labeling machines often include adjustable guides and cleaning stations to handle different bottle sizes. Complex packages (multiple panels) may need multi-head systems.

- Label Material and Adhesive: Decide if labels are pressure-sensitive (paper or film) or shrink sleeves. For shrink sleeve machines, you also need a shrink tunnel. Labels requiring special adhesives (waterproof, removable) may influence applicator choice. If using RFID labels, ensure the printer supports encoding.

- Integration and Controls: Determine how the labeler will fit into your line. Will it feed from a conveyor, or is it standalone? What software/PLC interfaces are needed? Many modern labelers have human-machine interfaces (HMIs) for easy recipe changes and network connectivity for traceability systems.

- Flexibility: If you label many products or seasonal SKUs, choose a machine with quick changeovers (adjustable or tool-free adjustments) and software memory for label formats. Semi-auto machines can sometimes be upgraded to automatic units by adding hoppers or conveyors.

- Budget and Maintenance: Balance cost against ROI. Fully automatic systems cost more but save on labor over time. Check maintenance requirements (spare parts, cleaning), and whether the manufacturer provides training and support. A reliable machine should minimize downtime and offer consistent performance for years.

Consulting with labeling machine manufacturers and reviewing case studies can help in decision-making. Matching the machine capabilities to your specific product and label requirements ensures optimum efficiency. In all cases, a well-integrated labeling solution will improve line efficiency, reduce errors, and support high-quality branding.

Evolving Trends

Labeling machinery continues to advance with technology trends. Key developments include:

- Smart Manufacturing Integration: Modern labelers often include IoT connectivity and data logging. This enables real-time monitoring of production rates, quick fault diagnosis, and remote updates. For example, some machines can automatically adjust for minor variations in container speed or position using machine vision.

- Digital Printing Technologies: As digital printers become faster and more affordable, more lines use on-demand printing instead of pre-printed labels. This reduces waste and allows last-minute changes. UV inkjet printing and digital embossing are also emerging for custom, short-run labels.

- Advanced Materials: Sustainable and smart label materials are on the rise. Biodegradable label stocks and water-based adhesives cater to eco-friendly packaging. RFID and NFC inlays are integrated into labels for interactive packaging and supply-chain tracking.

- Robotics and Multi-function Stations: Some systems now use robotic arms to handle products, combine labeling with other tasks (like capping or inspection), or apply labels at unconventional angles. Carousel labelers (rotary systems) continue to improve for ultra-high-speed lines.

While core principles of labeling remain, the drive for higher flexibility, traceability, and efficiency pushes manufacturers to adopt these innovations. Companies seeking to stay competitive should look for labeling equipment that supports future upgrades and evolving standards.

Conclusion

Industrial labeling machinery is a cornerstone of modern manufacturing, ensuring products carry the necessary information and branding. By automating label application, companies achieve higher speeds, consistency, and quality than manual methods. A variety of specialized machines – from automatic bottle labelers to shrink-sleeve systems – serve different product types and industries. Critical components like label applicators, conveyors, and integrated printers work together to apply labels accurately at scale. The result is streamlined production lines, lower labor costs, and compliance with industry standards. When designed and selected properly, labeling equipment enhances product presentation and operational efficiency, giving businesses a competitive edge in packaging.

FAQs About Industrial Labeling Machinery

What is industrial labeling machinery?

Industrial labeling machinery refers to automated systems designed to apply labels—such as branding, barcodes, or regulatory information—onto products (e.g. bottles, jars, cartons) with precision and speed, replacing labor-intensive manual labeling methods.

What types of labeling machines are available?

There are manual, semi-automatic, and fully automatic labeling machines; various applicator types like pressure-sensitive (peel-and-stick), shrink sleeve, and print-and-apply systems; and category-specific machines for bottles, jars, vials, cartons, etc.

How does a print-and-apply labeling machine work?

A print-and-apply machine prints labels on-demand (like batch codes or QR codes) on blank stock and immediately applies them to moving products, eliminating pre-printed label inventory and increasing traceability.

Why should I choose a shrink sleeve labeling machine?

Shrink sleeve machines offer 360° full-surface coverage, tamper-evident features, and highly attractive graphics—ideal for brands looking to maximize visual impact and label protection.

What are the benefits of automated labeling machines over manual ones?

Automated systems provide higher throughput, greater accuracy, consistent placement, reduced labor costs, improved durability, better compliance, and flexibility to switch formats quickly.

Which industries use industrial labeling machinery?

Common industries include food & beverage, pharmaceuticals, cosmetics, chemicals, electronics, automotive, logistics and e-commerce; each requiring tailored labeling solutions for different container types and compliance needs.

How do I choose the right labeling machine for my product?

Consider production volume, container shape and size, label type (pressure-sensitive vs. shrink sleeve vs. RFID), integration with production lines, flexibility needs, and budget/ROI when selecting a labeling system.

What is the difference between semi-automatic and fully automatic labeling machines?

Semi-automatic machines require operator involvement (e.g. feeding products or triggering labels), while fully automatic machines integrate inline, operate at high speed, and need minimal human oversight.

How does a label applicator like tamp-blow or wipe-on work?

In tamp-blow, a pad pushes the label onto a product and compressed air blows it off; in wipe-on, a brush or roller physically presses the label onto the container surface—both ensure precise application suited to different materials and speeds.

How is industry traceability achieved through labeling machines?

Through print-and-apply systems and integrated RFID/barcode printing, labeling machines enable real-time coding of batch numbers, serial IDs, QR and RFID tags, enhancing traceability, compliance, and supply-chain tracking.

| References: | |

| 1. | Automation Application in Product Labeling: Benefits,Challenges, Key Components and Technologies: A Review ——Retrieved from:UNIMMA Journal |

| 2. | Wikipedia – Label dispenser |

| 3. | Modular Industrial Labeling and Stamping System with Conveyor Integration Using PLC Controller ——Retrieved from:ResearchGate |

| 4. | 6 Benefits of Upgrading To Shrink Sleeve Labels ——Retrieved from:Onlinelabels.com |

Comments