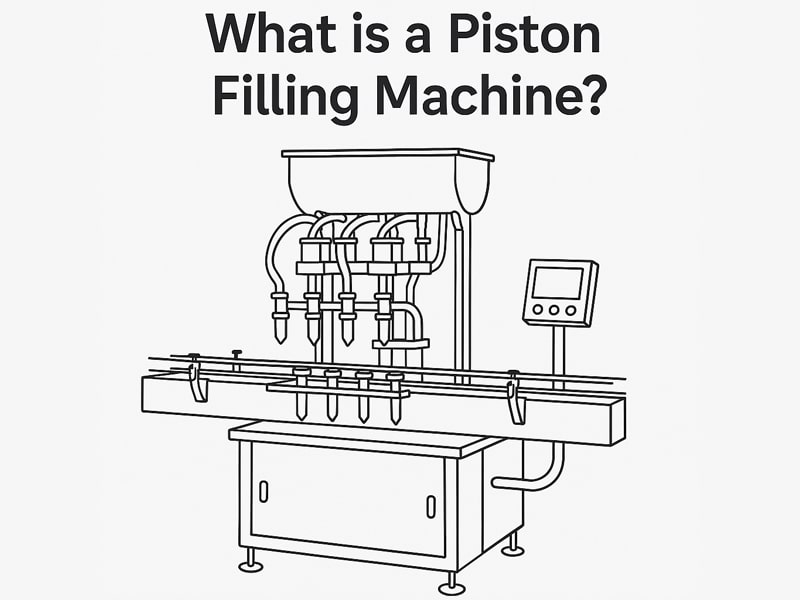

What is a Piston Filling Machine?

A piston filling machine is a type of liquid filling machine that uses a piston and cylinder mechanism to measure and dispense precise volumes of product into containers. It is a volumetric filler, meaning each fill is a fixed volume determined by the piston bore and stroke. Piston fillers can handle a wide range of viscosities – from thin free-flowing liquids to thick pastes and even formulas with particles or chunks (e.g. fruit pieces). This flexibility makes piston fillers widely used across many industries, from food processing to chemicals.

How Piston Filling Machines Work

Piston fillers operate on a simple draw-and-dispense cycle. A hopper or bulk tank stores the product to be filled. When a fill cycle starts, a valve opens from the hopper to the cylinder and the piston withdraws from the cylinder, drawing product into the cylinder chamber. Once the piston reaches the programmed fill position (determining the volume), the valve switches to isolate the hopper and open the path to the nozzle. The piston then pushes forward, forcing the product through the nozzle and into the container.

This draw-and-dispense action creates a consistent volumetric fill each time. Since the interior volume of the cylinder never changes, each stroke delivers the same amount of product. In practice, piston fillers achieve very high fill accuracy (often within ±1% or better).

The main components of a piston filling machine include the hopper or tank, valve, cylinder, piston, and nozzle. The piston is precisely machined with airtight seals, and the cylinder is matched to the piston for accurate draws. During drawing, product flows from the hopper into the cylinder; during dispensing, the valve directs product through the nozzle into the container. The nozzle itself can be swapped or customized for the product and container – for example, wide-bore nozzles can be used for chunky sauces, while narrow nozzles fit small-neck bottles.

Modern piston fillers may use pneumatic cylinders or electric drives; many advanced designs use servo motors. In a servo piston filler, each piston head is controlled by a servo motor, allowing smooth, programmable motion and precise fill control. This electronic control is ideal for high-speed operation and fine volume adjustments without mechanical wear.

Types of Piston Filling Machines

Piston filling machines come in both semi-automatic and fully automatic forms. Semi-automatic machines require an operator to place containers and trigger the fill (usually via a foot switch or button). Fully automatic piston fillers integrate into production lines with conveyors, infeed systems, and PLC controls for continuous operation.

Key variants include single-head vs. multi-head machines, and specialty types like piston follower fillers. A multi-head piston filler has several piston-nozzle assemblies working in parallel; each head fills a container independently, multiplying output capacity. SFXB’s XBGG series is an example of a multi-head servo-driven piston filler capable of very high throughput.

A piston follower filling machine uses a follower plate to maintain constant pressure on the product in a drum or tank. As the pistons draw product, the follower (like a weighted lid) moves down, keeping the product always in contact with the piston intake. This is useful for very viscous products that would otherwise clog. SFXB’s Double Head Piston Follower Filling Machine uses two pistons with follower plates to feed high-viscosity sauces and pastes.

Regardless of configuration, all piston fillers operate on the same volumetric principle: each piston stroke draws a fixed volume and then dispenses it. Because of this, piston filling machines are often called volumetric piston fillers in industry literature.

Applications and Industries

Piston filling machines are widely used across food & beverage, cosmetics & pharmaceuticals, household & industrial chemicals, and other sectors. They are ideal wherever precise dosing, repeatability, and viscosity handling are important.

● Food & Beverage: Piston fillers handle a wide variety of food products. Common uses include filling sauces (ketchup, mustard, chili sauce), jellies, jams, dressings, syrups, honey, yogurt, juices, dairy products, and even beverages like bubble tea or kombucha. For example, SFXB’s multi-head piston filler is specifically suited to sauces and liquids (honey, chili sauce, tomato sauce, fruit juices, pearl milk tea, etc.).

● Cosmetics & Pharmaceuticals: Precise fill volume is critical in personal care and pharma. Piston fillers are used for creams, lotions, gels, ointments, shampoos, liquid soaps, toothpaste, liquid nutrients and syrups. They ensure each bottle or tube gets the same dosage with ±1% accuracy. The high fill accuracy makes them “highly favored by the cosmetic and pharmaceutical industries”.

● Household & Chemicals: Liquid detergents, cleaning solutions, oils, lubricants, and other chemical products can be filled with piston machines. These products can be thin or viscous; piston fillers can easily switch configurations. The robust stainless construction also resists corrosion from chemicals. NPack notes their piston fillers are suitable for food, chemical, and cosmetics sectors, highlighting broad industrial use.

● Specialty Products: Because piston fillers can be constructed with sanitary materials, they serve niche markets like nutraceuticals or lab solutions. The use of 316L stainless steel and FDA-approved components means they meet high sanitation standards. For example, nutrient supplements, edible oils, or dairy enhancers often use piston filling technology to maintain purity and consistency.

In summary, piston filling machines can accommodate virtually any liquid or paste product. Their adaptability allows packaging lines to change from one product to another (e.g. from a thin lotion to a thick sauce) with minimal adjustment. This is why piston fillers are “widely used in various packaging industries”.

Advantages of Piston Filling Machines

Piston filling machines offer several advantages over alternative filling methods:

● High Fill Accuracy: Because each piston stroke displaces a set volume, piston fillers deliver very consistent fills. The fixed cylinder volume means even small fill variations (±1% or less) can be achieved. Accurate filling reduces product giveaway and ensures uniformity.

● Wide Viscosity Range: Piston fillers handle products from very thin to very viscous. Unlike gravity or overflow fillers (which require free-flowing liquid), pistons actively draw product, so they work with thick creams, gels, pastes, and even particulate-containing liquids. For example, sauces with chunks or fibrous materials can be filled if the nozzle is sized appropriately. SFXB notes that servo piston fillers are excellent for highly viscous and foamy substances.

● Versatility & Flexibility: One piston filling machine can often be adapted to multiple products and container sizes. Changing a fill volume can be as simple as adjusting the piston stroke length or swapping in a different piston diameter. Multi-head machines can be scaled (e.g. 2, 4, 6, 8 heads) to match output requirements. This versatility makes piston fillers a favorite in the food industry.

● Easy Maintenance and Cleaning: Many piston filler designs allow quick disassembly of product-contact parts without tools. Fast access to pistons and valves means production downtime for cleaning or changeover is minimized.

● Hygienic Construction: Most piston fillers use polished stainless steel (304 or 316L) and FDA/USDA-approved seals. This ensures food safety and chemical compatibility. The polished surfaces and open designs make it easier to meet GMP and sanitation standards.

● High Output Capability: With multiple filling heads and synchronized drives, piston fillers can achieve high speeds.

● Consistent Performance: Piston fillers actively pump the product, so fill performance is consistent regardless of supply level. As one source notes, the cylinder’s volume never changes, so each container receives exactly the same volume. This predictability is valuable in automated lines.

Compared to other filling methods, piston fillers excel with challenging products. Pump fillers, for example, may struggle with very thick sauces or require complex gear pumps. In contrast, a piston’s volumetric mechanism naturally handles high-viscosity fluids. Similarly, gravity or overflow fillers cannot manage particulate or high-viscosity products. In short, the precise volumetric design of piston machines makes them a go-to solution for many liquid packaging challenges.

SFXB’s Piston Filling Solutions

SFXB offers advanced piston filling machines designed for custom liquid packaging lines. Two notable products are:

● XBGG Series Automatic Multi-Head Servo Piston Filling Machine: A high-speed, multi-head piston filler driven by servo motors on each head. It is ideal for filling various sauces, pastes, and liquids (including those with soft particles) such as honey, chili sauce, tomato sauce, pearl milk tea, coconut fruit juice, orange juice, etc.. The multi-head design delivers very high throughput, and servo control ensures smooth, repeatable fills. The XBGG series can be integrated into an automated filling line with conveyors and capping equipment for turnkey operations.

● Double Head Piston Follower Filling Machine: This model features two piston heads with follower plates (to maintain product level) for medium-volume filling. It typically handles 200–500 mL containers at speeds around 20–40 bottles per minute with ±1% accuracy. It can fill liquids, pastes and sauces (including those with soft particles) like honey, chili sauce, tomato sauce, fruit juices, etc.. The follower plate design ensures a steady feed of very viscous product to the pistons.

Both of these piston fillers from SFXB emphasize customization and integration. Customers can choose the number of heads, piston sizes, and hopper configurations to match their production needs. The machines use sanitary stainless steel contact parts and can be outfitted with PLC controls, touchscreens, and sensors for automated operation. For example, optional features include anti-drip nozzles, height adjustment, and CIP (clean-in-place) kits. SFXB often delivers these piston fillers as part of a complete packaging system, ready to run as part of a customer’s production line.

Customization and Integration

Piston filling machines can be highly customized for each packaging project. SFXB and other manufacturers typically offer:

● Adjustable Fill Volume: Piston stroke length and diameter can be changed to meet exact volume requirements. This allows one machine to accommodate both small and large containers.

● Multiple Heads: Machines can be built with 1, 2, 4, 6, 8 or more filling heads, depending on output needs. More heads means higher throughput.

● Materials and Seals: Components (pistons, cylinders, gaskets) can be selected for the product. For instance, pistons may be 316L stainless or even titanium, tanks can be 304 or 316L SS, and seals are typically PTFE or FDA-grade materials.

● Nozzle Design: The filling nozzle can be customized (different bore sizes, dip tubes, or bottom-up fill designs) to match container shape and prevent drips.

● Control Systems: Modern piston fillers include PLC/HMI control systems for recipe programming, speed adjustment, and safety interlocks. Fill parameters can be saved and quickly changed for different products.

● Integration: Piston fillers integrate with other packaging machines. SFXB often ties its piston fillers into automated lines with conveyors, cappers and labelers for seamless production.

● CIP/SIP Features: For sanitary operations, machines can include clean-in-place (CIP) systems that wash the product path without disassembly.

By tailoring these options, the piston filling machine becomes a custom machine for packaging specific liquid products. Whether filling edible oils in glass bottles or lotions in plastic jars, the right configuration ensures efficient, reliable operation. The combination of customization and proven volumetric technology is why many buyers choose piston fillers for new packaging lines.

Conclusion

In summary, a piston filling machine is a precision volumetric filling solution suitable for a wide range of liquids and semi-solids. It works by drawing product into a cylinder and then dispensing a fixed volume, providing highly consistent fills. Piston fillers offer advantages such as excellent accuracy, flexibility to handle different viscosities, and hygienic construction.

For example, by adjusting the piston stroke length, operators can fine-tune the fill volume for any bottle size. Multi-head servo models can achieve high line speeds while maintaining uniformity. And even very thick sauces with particulates can be filled effectively, as shown by SFXB’s specialized machines.

Overall, piston filling machines are a go-to choice in many industries where precise liquid packaging is required. They provide a robust solution for products ranging from sauces and lotions to detergents and oils. Leading providers like SFXB supply customizable servo-driven piston fillers and turnkey systems that help manufacturers achieve efficient, accurate packaging on a global scale.

Frequently Asked Questions (FAQs)

1.What is a piston filling machine?

A piston filling machine is a volumetric liquid filling system that uses a piston moving inside a cylinder to draw and dispense a fixed volume of product. It handles everything from thin, free-flowing liquids to high-viscosity pastes and products containing particulates.

2.How does a piston filling machine work?

● Fill (draw) stroke: A valve opens to the hopper, and the piston retracts, drawing product into the cylinder.

● Dispense stroke: The inlet valve closes, the outlet valve opens to the nozzle, and the piston advances, pushing the exact volume of product into the container.

3.What are the main components of a piston filler?

● Hopper or bulk tank

● Inlet and outlet valves

● Cylinder and piston assembly

● Filling nozzle (interchangeable)

● Drive system (pneumatic cylinder or servo motor)

● Control system (PLC/HMI)

4.What advantages does a servo-driven piston filler offer?

● Precise, programmable piston stroke control for high fill accuracy

● Smooth acceleration/deceleration to reduce splashing

● Easy recipe changes and integration into automated lines

5.What is a piston follower filling machine?

A piston follower filler uses a weighted or spring-loaded follower plate in the product drum. As the piston draws product, the follower plate descends, ensuring continuous feed of very viscous materials (e.g., thick sauces, gels).

6.How do piston fillers compare to other filling methods?

● Accuracy: Volumetric control yields fill tolerances as tight as ±1%.

● Viscosity range: Actively draws product, so it handles thin to very thick fluids and particulates.

● Flexibility: Easily adjust volume or switch products by changing stroke length or piston diameter.

● Cleanability: Quick-release valves and pistons allow fast disassembly for cleaning.

● Sanitary construction: Polished stainless steel and FDA-grade seals meet hygiene standards.

7.What is a multi-head piston filling machine?

A multi-head machine has two or more piston/nozzle assemblies operating in parallel, multiplying output capacity while maintaining the same volumetric accuracy on each head.

8.Which industries benefit most from piston filling machines?

● Food & Beverage: Sauces, jams, honey, juices, yogurts, tea drinks

● Cosmetics & Pharmaceuticals: Creams, lotions, gels, syrups, toothpaste

● Household & Industrial Chemicals: Detergents, lubricants, cleaning solutions

● Specialty Products: Nutraceuticals, laboratory reagents

9.How can I ensure efficient cleaning of a piston filling machine?

● Use quick-release, tool-free valves, pistons, and nozzles.

● Implement a CIP (clean-in-place) system to flush product lines without disassembly.

● Regularly inspect and replace seals to maintain sanitation and prevent leaks.

10.What customization options are available?

● Stroke length and cylinder diameter: Match container sizes and volumes.

● Nozzle design: Various bore sizes, bottom-up fill, anti-drip tips.

● Drive system: Pneumatic, servo, or electric drives.

● Head count: Single to multi-head configurations for different output rates.

● Control features: PLC/HMI recipe management, upstream/downstream integration, CIP modules.

| References: | |

| 1. | Food processing machinery. Filling machines and interchangeable equipment. Safety and hygiene requirements –Retrieved from: EUROPEAN STANDARD |

| 2. | Experimental Study on the Influencing Factors of Piston Liquid Filling Accuracy –Retrieved from: ResearchGate |

| 3. | Standard Operating Procedure for Piston Filling Machine –Retrieved from:SOP Guide for Pharma |

Comments