Pet food packaging is more than just a container – it’s a critical factor in preserving nutrition, ensuring safety, and building brand trust. With pet ownership on the rise, pet food manufacturers must balance cost, quality, and sustainability. For example, one packaging industry guide notes that 99% of U.S. pet food packaging waste (about 300 million pounds of plastic per year) ends up in landfills or oceans, underscoring the need for recyclable and eco-friendly solutions. A well-designed pet food package keeps kibble crunchy or wet food fresh longer, communicates nutrition information to pet owners, and conveys brand values (like “natural” or “organic”) through colors and images. As Guangzhou SFXB (XueBa) notes, it is “one of the premier packaging machinery manufacturers specializing in non-standard automatic filling production line equipment,” reflecting how key packaging technology is for pet food lines.

Why Packaging Matters in Pet Food

Pet food packaging preserves freshness, extends shelf life, and protects against contamination. Good packaging acts as a barrier to oxygen, moisture, and light – factors that cause fats to oxidize and nutrients to degrade. For instance, fresh pet foods and treats often require vacuum-sealed or nitrogen-flushed pouches so fats don’t turn rancid, keeping products fresh 3–5× longer than normal conditions. Similarly, rigid containers (like metal cans or plastic tubs) block UV rays and air for wet foods, while resealable zip-lock bags for dry kibble help prevent staleness after opening.

Packaging also shapes brand reputation. Labels and design highlight key benefits – e.g. “grain-free,” “protein-rich,” or images of happy pets – which resonate with owners’ preferences. In fact, one industry report found that smaller, convenient pouches are increasingly used for pet foods: “pouches help ensure freshness more than traditional bulk, paper bags,” and allow features like resealable zippers and gas-flushing to extend shelf life. Key Takeaway: Effective pet food packaging combines strong barriers (to protect quality) with smart design (to attract pet owners).

Key Packaging Formats and Materials

Pet foods come in many formats, and each has a typical package style:

- Stand-Up Pouches & Resealable Bags: Very popular for dry kibble, treats, and individual portions of wet food. Multi-layer laminated films (plastic/foil composites) provide excellent moisture and oxygen barriers. These lightweight, flexible bags often include resealable zippers for freshness and flat bottoms to stand on shelves. Such flexible packaging is cost-effective and space-saving – studies show it can use less material and reduce shipping weight, while still protecting flavor.

- Rigid Cans, Jars, and Trays: Common for wet and semi-moist foods. Metal cans (aluminum or steel) are lined for safety and protect food from light/air. Plastic tubs or trays (with snap-on lids or foil seals) also keep out oxygen. Rigid packaging provides impact resistance for shipping and is perceived as premium. For example, dog food packaging for wet formulas often uses durable cans or tubs, while cat food packaging might use smaller cans sized for single meals.

- Paperboard/Box Packaging: Used mainly for multipacks or dry food “sleeves.” Eco-conscious brands sometimes use paperboard with a plastic or foil liner for strength. Kraft paper bags (with inner plastic liners) offer recyclability but must be well-sealed to avoid moisture ingress.

- Specialty Formats: Sachets or sticks for single-serve treats, bulk sacks for manufacturers, and even edible or water-soluble films for innovative products.

Each material has trade-offs. Flexible films are light and seal tightly (and can incorporate recycled content), but can be harder to recycle if multi-layer. Rigid plastics and metals are easily recycled but use more raw material. The right choice depends on the product’s moisture/fat content, desired shelf life, cost constraints, and sustainability goals.

Wet vs. Dry Pet Food Packaging

Pet food packaging must match the product type:

- Wet Pet Food (canned, stews, pâtés): Requires airtight containers. Metal cans are classic – they block oxygen completely and can be retort-processed (heat-sterilized) to kill bacteria. Retort pouches (thick, multi-layer plastic/foil bags) are another option: these can be vacuum sealed and then sterilized. Both formats typically include easy-open features (like pull-tabs on cans or tear-notches on pouches) for consumer convenience.

- Dry Pet Food (kibble, biscuits): Most often sold in laminated plastic bags – either flow-wrapped rolls or pre-made bags. These bags have strong moisture barriers and usually a resealable zip to keep food fresh after opening. Sometimes dry food is packed in rigid plastic containers with snap lids (for reuse) or cardboard cartons lined with foil. Brands emphasize shelf-stable storage: one packaging study notes the importance of a moisture barrier and use of resealable zippers in dry food bags.

Pet Treat Packaging follows similar rules. Chewy or crunchy treats (like dog biscuits) are often in smaller pouches or stand-up bags, highlighting easy opening and reclosure. Freeze-dried treats and foods, which are very sensitive to air, frequently use multi-layer stand-up pouches (often with a zip) to extend shelf life even though the product has no moisture inside. Manufacturers may include transparent windows or colorful prints so dog treat packaging and cat snack packaging can showcase the product and stand out on store shelves.

Designing for Safety and Labeling

Regulations dictate what info pet food packaging must carry. Labels should list ingredients, guaranteed analysis (nutrients), feeding instructions, net weight, manufacturer info, and lot number. Following FDA (U.S.) or AAFCO (USA model feed standards) rules is mandatory. High-quality packaging prevents contamination: for instance, tamper-evident seals and food-grade materials (tested for chemical migration) ensure pet health. The industry has frameworks like ISO 22000 and HACCP to manage safety.

Good packaging design also educates consumers. Clear, legible labeling and ingredient lists build trust. Many brands now use QR codes printed on the package to give pet owners more information – such as detailed ingredients, sourcing, or feeding guidelines. Imagery and terminology (like “organic,” “grain-free,” or cute pet pictures) are powerful: as one industry guide says, stand-up pouches allow “bigger, bolder imagery” than cans, and the extra surface can advertise health claims prominently. For example, a cat food pouch might feature a happy cat photo and large text promoting vitamins, while a dog kibble bag might show a running dog and highlight protein content.

Sustainability in Pet Food Packaging

Environmental concerns are reshaping pet food packaging choices. Consumers are increasingly willing to pay more for greener options. In fact, a recent European study found that 76% of pet owners consider a product’s overall sustainability and 69% specifically care about sustainable packaging when buying pet food. This means recyclability and recycled content are huge priorities. Brands are responding by: adopting mono-material films for easier recycling, introducing post-consumer recycled (PCR) plastic in bags, and offering paper-based options where feasible.

Flexible packaging is evolving too: new compostable laminates and recycled polymer films (like all-polyethylene pouches) are becoming available. For example, Amcor and other suppliers now offer recycle-ready heat-resistant pouches for wet food and specialty laminated films for dry food that balance barrier performance with recyclability. At the same time, rigid packaging can use recycled plastics and metals – a steel or aluminum can is highly recyclable and can carry labels noting “recyclable” to appeal to eco-minded buyers.

Key sustainable practices include: using lighter-weight materials (to cut transport emissions), minimizing inks and laminates, and clearly marking how to recycle the package. Brands often promote these efforts on-pack; one report notes that consumers trust claims like “recyclable packaging” over vague ones. Importantly, longer shelf life (achieved by better barriers or zipper tops) reduces food waste, which is itself a sustainability win. In summary, integrating eco-friendly materials (biodegradable films, PCR content) can boost loyalty from conscious pet parents while still maintaining product protection.

Automation and Packaging Machinery

Modern pet food production relies on automated equipment for hygiene, speed, and consistency. Xuebapack’s knowledge base notes that “regardless of the food type, this packing is done with an automated food packaging machine” – and pet food is no exception. Common machines in a pet food line include:

- Weighing & Bagging Machines: High-precision weighers feed dry kibble or treat pieces into open-mouth baggers. As one industry source notes, foods like rice, sugar, and pet foods are often packed by these systems into pre-made bags. These baggers then heat-seal or stitch the bags, ensuring each package has the exact weight.

- Vertical Form-Fill-Seal (VFFS) Machines: These make stand-up pouches or side-gusset bags from a roll of film, fill them with product (dry or wet), and seal on top. VFFS machines can run hundreds of bags per minute and often include a gas-flushing station to displace oxygen before sealing (boosting freshness). Xuebapack provides VFFS pouch machines tailored to pet products, with options for vacuum/modified-atmosphere packaging and Z-sealers for firmness.

- Flow Wrappers: For snacks and treats (like biscuits or bars), horizontal flow wrappers wrap individual items in film, sealing the ends. They produce pillow packs or twist-wrap packages quickly, keeping each piece protected from moisture.

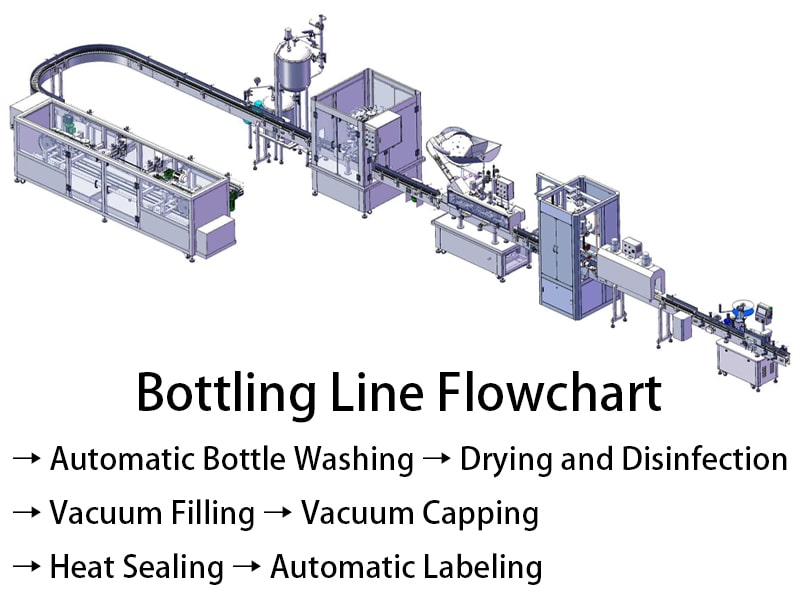

- Liquid Filling & Capping Machines: For canned or bottled pet foods (like gravies or supplements), rotary or inline fillers accurately portion the wet food into cans, tubs, or jars, and automatically apply lids or peelable seals. This is often integrated with conveyors and labelers in one production line.

- Inspection Systems: Checkweighers weigh every package post-sealing to reject any with incorrect fill, and metal detectors or X-rays screen for foreign materials. These safeguard product safety and quality.

Automated packaging lines (like SFXB’s systems) minimize human error and increase throughput. For instance, precision multi-head weighers can feed the exact count of kibble or treats, while conveyors move packages through heat-sealers or case packers seamlessly. Investing in proper machinery ensures consistent portion sizes, strong seals, and traceability, all of which are essential in a regulated pet food industry.

Best Practices and Tips

- Choose the Right Barrier – Match your packaging material to the product’s needs. Use aluminum or laminated films for high-fat or sensitive products. For dry foods, ensure an effective moisture barrier. Many brands are now choosing reclosable zipper pouches or easy-peel lids to extend freshness after opening.

- Prioritize Safety and Compliance – Always use food-grade, FDA-approved packaging materials. Include clear lot codes and expiration dates on the package (or inner bag) to help with traceability. Conduct routine QC checks; as industry experts note, integrating quality control into daily operations is key to preventing recalls.

- Streamline for Efficiency – Optimize package size and shape to fit standard shipping and display units. For example, designing stand-up pouches that pack snugly on a shelf or pallet can reduce wasted space. Involving logistics and production teams early can cut freight and storage costs.

- Enhance Consumer Experience – Highlight pet-specific benefits on-pack and ensure the packaging is user-friendly. Features like tear notches, clear portion guidelines, and memorable branding elements (happy pet images, bold fonts) can improve satisfaction. Including pet feeding tips or fun facts via QR codes can also engage modern consumers.

- Adopt Sustainable Solutions – Whenever possible, use recyclable or compostable materials, and communicate this on the package. Consider lighter-weight materials to reduce carbon footprint. Stay informed about recycling infrastructure (e.g., many curbside programs now accept aluminum or certain plastics). Remember that eco-friendly choices can enhance your brand’s image among the 69–76% of pet owners who value sustainable packaging.

By following these guidelines – and continuously iterating with testing and market feedback – pet food brands can create packaging that protects their products, appeals to pet lovers, and stays ahead of industry trends. In an era of “pet humanization” and premiumization, great packaging is not just functional, it’s part of the pet-parent experience and trust.

Frequently Asked Questions (FAQ) About Pet Food Packaging

1. What is pet food packaging and why is it important?

Pet food packaging refers to the materials and containers used to store and present pet food—including kibble, wet food, treats, and pouches. It is crucial because it preserves freshness, prevents oxidation and moisture ingress, protects against contamination, extends shelf life, and communicates nutritional and brand information to consumers.

2. How does packaging reduce oxidation and extend shelf life?

By employing materials with strong barrier properties (e.g., EVOH, PVDC, aluminum), using oxygen scavengers, nitrogen flushing, and vacuum or modified atmosphere packaging (MAP), pet food packaging limits oxygen exposure, slowing down rancidification and microbial spoilage to preserve nutrition and flavor.

3. What types of packaging formats are common for dog food and cat food?

Typical formats include stand-up resealable pouches for dry kibble, rigid cans or tubs for wet food, laminated plastic or foil bags for treats, and paperboard cartons with barrier liners. Choice depends on product type, moisture content, and desired shelf life .

4. What are the best packaging options for pet treats?

Pet treat packaging generally uses multi-layer flexible pouches with resealable closures and barrier films to preserve crunch and flavor. Transparent windows and vibrant graphics enhance shelf appeal. For freeze-dried or fat-rich treats, oxygen barrier films or gas-flushing are especially important.

5. How do regulations affect pet food packaging labels?

In the U.S., labels must comply with FDA and AAFCO guidelines. Required information includes brand/product name, species, net weight, guaranteed analysis, ingredient statement, nutritional adequacy, feeding directions, and manufacturer information. Claims must not be misleading or implying drug-like benefits.

6. What makes a packaging material "food-safe"?

Food-safe contact materials must be constructed from FDA- or equivalent-approved substances—such as plastics, coatings, or liners—that do not migrate harmful chemicals into food. They must meet regulatory standards like EC 1935/2004 in Europe or food contact substance notifications in the U.S.

7. Is vacuum sealing effective for pet food packaging?

Yes. Vacuum packing removes air and limits oxygen exposure, reducing aerobic spoilage and keeping product fresh longer. When paired with high-barrier films (like EVOH or PVDC), vacuum packaging significantly extends shelf life.

8. How long can pet food stay fresh in proper packaging?

Dry pet food in high-barrier packaging can remain fresh for 12–18 months unopened. Wet food in sealed cans or retort pouches may last up to 2 years. Once opened, dry food should ideally be used within 6 months if resealed and stored correctly (cool, dry environment).

9. What safety systems should packaging machinery include?

Packaging lines should feature inspection systems such as checkweighers to verify fill weight and metal detectors or X-ray units to catch foreign objects—ensuring consistent quality and regulatory compliance throughout production.

10. How does packaging support sustainability efforts?

Using recyclable materials—such as mono-polyethylene films, post-consumer recycled plastic, or recyclable cans—and reducing material weight helps reduce environmental impact. Sustainable packaging also reduces food waste via improved shelf life and aligns with rising consumer demand for eco-friendly products.

Comments