Introduction: The Unseen Powerhouses of Modern Production

In the intricate ecosystem of modern industry, filling machines stand as indispensable workhorses, the unsung heroes behind the seamless flow of products across diverse sectors. From the bustling aisles of food and beverage to the precision-driven realms of pharmaceuticals, cosmetics, and everyday household goods, these machines are far more than mere dispensers. They are the critical technological backbone ensuring product integrity and market readiness, meticulously calibrating every ounce and gram. Their importance cannot be overstated: they precisely dispense products, maintain unwavering consistency in weight and volume, streamline production processes, dramatically boost efficiency, and significantly curtail waste. Beyond the operational benefits, this precision also elevates a product’s aesthetic appeal and shelf presence, contributing to a professional, uniform brand image that resonates with consumers.

The landscape of filling machine technology is vast and nuanced, with each type meticulously engineered to meet the unique demands of specific product characteristics and production scales. This comprehensive guide aims to demystify these industrial marvels, delving into their underlying scientific principles with an accessible yet professional tone. Choosing the right filling machine is not merely a procurement task; it’s a strategic investment that directly impacts profitability and competitive advantage. In a market that relentlessly demands consistency and cost-efficiency, a well-chosen filling machine transcends its role as equipment, becoming a pivotal asset that shapes a company’s long-term viability and growth.

I. Decoding Filling Machine Automation: From Manual Dexterity to Integrated Intelligence

The spectrum of automation in filling machines is broad, designed to accommodate varying production volumes and investment capacities. This progressive evolution in automation often mirrors a company’s growth trajectory and the increasing sophistication of its operational demands.

Manual and Semi-Automatic Filling Machines: Starting Small, Staying Agile

At the entry point of automation, manual filling machines represent the simplest form. They require an operator to physically position each bottle, initiate the fill cycle (perhaps with a lever or button), and then remove the filled container. These machines are characterized by their low cost, ease of use, and typically feature a single filling nozzle, resulting in lower output—one bottle at a time. They prove ideal for extremely low-volume runs, nascent businesses, laboratory testing, or for dispensing highly viscous liquids where speed is not the primary concern, especially in environments with unreliable power sources.

Stepping up in automation, semi-automatic filling machines still necessitate operator involvement for loading and initiating the fill cycle (often via a foot pedal or button). However, they typically integrate powered pumps or pistons and may feature multiple nozzles. Compared to their manual counterparts, semi-automatic models offer enhanced accuracy and speed, delivering faster fills and more consistent volumes. They strike a commendable balance between cost and output, making them an economical yet efficient choice for small to medium-sized production batches. Their adaptability allows them to handle a diverse range of products, from personal care items to pharmaceutical applications.

Fully Automatic Systems: Scaling for High-Volume Production

For high-volume production, fully automatic filling machines are the industry standard. These sophisticated systems manage the entire process, from bottle conveyance and filling to capping and labeling, with minimal human intervention. They typically employ conveyor systems to ensure a continuous flow of containers through various stations.

Inline filling systems utilize a straight conveyor line, guiding bottles into the filling nozzles before moving them to downstream processes like capping and labeling. They are easily integrated into existing production lines and can accommodate a wide array of container sizes, including larger volume fills. These systems often feature integrated components such as printers, labelers, and cappers, further reducing manual labor.

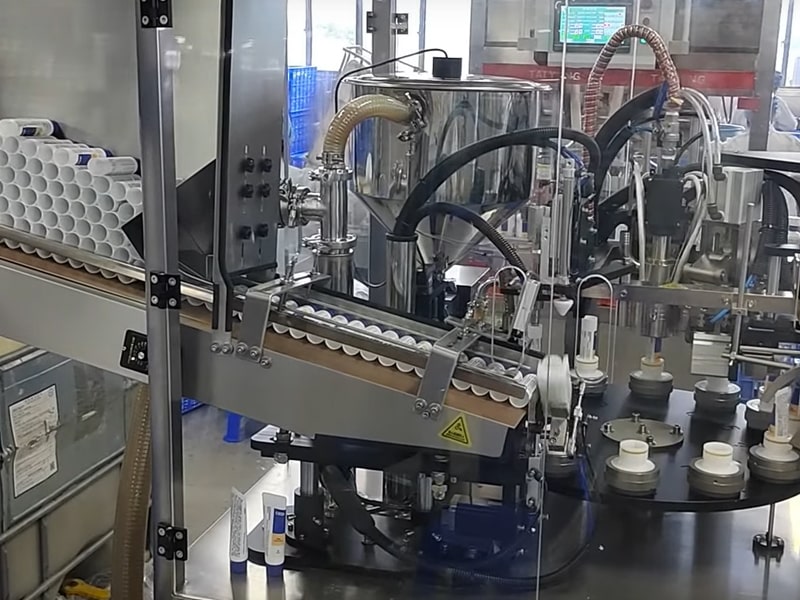

Representing the pinnacle of automation and technological integration, monobloc liquid filling systems consolidate multiple functions—such as uncapping, filling, and re-capping, along with other ancillary equipment—onto a single machine frame.

Monobloc filling machines are engineered for high-speed, large-scale packaging operations, prioritizing maximum efficiency and throughput. While their comprehensive automation capabilities come with a higher initial investment, their long-term benefits in terms of reduced labor costs and consistent output make them a preferred choice for larger enterprises.

Modern automatic filling machines leverage advanced components like servo-driven pistons or pumps, multi-head fillers, and programmable logic controllers (PLCs) to achieve unparalleled precision. They can attain exceptionally high throughput rates, often reaching tens of thousands of bottles per hour in large-scale facilities, and are designed for rapid adjustments to accommodate different bottle sizes.

The decision regarding the level of automation hinges on factors such as labor availability, production demands, and available floor space. It is also prudent to plan for future upgrade capabilities, as most packaging operations are geared towards growth. The progression in filling machine automation is more than just an increase in speed; it reflects a strategic scaling of a company’s operations. Manual fillers offer a low barrier to entry, semi-automatic machines enhance consistency and output without massive capital expenditure, and fully automatic systems signify a commitment to large-scale production and seamless integration. This phased approach allows businesses to select a system that aligns with their current needs and budget, while providing a clear pathway for future expansion. Thus, the chosen level of automation in a filling machine directly embodies a company’s production maturity and strategic vision, enabling incremental investments that support scalable growth rather than inflexible, all-or-nothing commitments.

II. A Deep Dive into Diverse Product Filling Machines

This section systematically explores the primary categories of filling machines, detailing their core principles, product suitability, key applications, and comparative advantages and disadvantages.

| Filling Machine Type | Ideal Product Form/Viscosity | Key Principle | Typical Accuracy | Typical Speed Range | Common Container Types | Main Advantages | Main Disadvantages |

| Liquid Filling Machines | |||||||

| Gravity Filler | Thin, low viscosity liquids | Gravity | ±1% | 20-36 BPM | Bottles, Jars | Cost-effective, simple operation, gentle on foamy products, good visual consistency | Not for high viscosity or particulate products, lower weight accuracy |

| Piston Filler | Viscous liquids/pastes, with particulates | Volumetric | ±1% | Up to 100 strokes/min | Bottles, Jars, Tubes | High precision, versatile, handles particulates well, reduces waste | May be limited by container size, more complex than gravity |

| Pump Filler | Wide viscosity range, sensitive products | Pumping | ±0.5% to ±2% | 0-5000 mL/min | Bottles, Jars, Tubes | Hygienic, high precision, fast changeover, easy maintenance, versatile | Some types are costly, may require gravity feed |

| Overflow Filler | Low to medium viscosity, foamy products | Level-based | High (visual) | High speed | Bottles, Glass, Metal | Consistent visual level, effective foam handling, minimal product loss | Not for high viscosity, recirculation may degrade product |

| Vacuum Filler | Thin liquids, oxygen-sensitive products, fine powders | Vacuum | Precise | Up to 250 bottles/hour | Bottles, Jars | Gentle, no-spill, removes residual air, reduces dust | Can be slower |

| Powder Filling Machines | |||||||

| Auger Filler | Free-flowing & non-free-flowing powders | Volumetric/Weight-based | <1% | Up to 70 bags/min | Bottles, Jars, Bags | High accuracy, versatile, controllable, dust control | Can be abrasive, may need different tooling |

| Volumetric Cup Filler | Free-flowing, granular, consistent density powders | Volumetric | Up to 1% | 30-80 bags/min | Bags, Containers | High speed, simple operation, cost-effective, flexible | Less accurate for varying densities, not ideal for high-value products |

| Net Weight Filler | High-value or regulated powders, varying density | Weight-based | ±0.25% to ±1% | 2-6 BPM | Containers, Bags | Highest accuracy, consistent, versatile, reduces waste | Slower, higher initial cost |

| Vacuum Powder Filler | Fine, dusty, aerated, non-free-flowing powders | Vacuum | Precise | Slower | Containers, Bags | Minimizes dust, handles difficult powders, preserves quality | Can be slower, not for all powder types |

| Vibratory Filler | Granules, powders, small parts | Vibration/Weight-based | High | Hundreds of containers/min | Containers | High accuracy, gentle on product, increases throughput | |

| Pouch Packing Machines | |||||||

| VFFS Machine | Free-flowing products, liquids, powders, granules | Vertical Form-Fill-Seal | ≤±1.5% | 30-160 bags/min | Flexible pouches | High speed, compact design, versatile, cost-effective, product safety | Higher initial investment, requires technical knowledge |

| HFFS Machine | Horizontal packaging, irregular/fragile products | Horizontal Form-Fill-Seal | Precise | High speed | Flexible pouches | More precise operation, flexible, handles irregular products well | Larger footprint than VFFS |

| Premade Pouch Filler | Liquids, powders, granules, blocks | Fill-and-Seal | ±0.1% to ±1% | 25-68 bags/min | Premade pouches | Pouch diversity, simplified operation, high speed, high accuracy, quick changeover | Premade pouch cost may be higher |

| Tube Filling Machines | |||||||

| Tube Filler | Pastes, gels, semi-solids | Volumetric | ±1% | 60-120 tubes/min | Plastic, laminate, metal, aluminum tubes | High precision, speed, reduced labor, versatile, hygienic | |

| Can Filling Machines | |||||||

| Can Filler | Carbonated beverages, liquids, aerosols | Isobaric/Pressure | Precise | 300-70,000 CPH | Aluminum, steel cans | Maintains carbonation, reduces oxygen, high speed, anti-foaming | Specialized for carbonated products |

| Water Bottling Machines | |||||||

| Water Bottling Machine | Water, non-carbonated beverages | Gravity/Overflow | 99.9% | 2000-36000 BPH | PET bottles, glass bottles, 5-gallon bottles | High production speed, enhanced hygiene, consistency, cost savings | Relatively costly, high power consumption, not for viscous products |

A. Liquid Filling Machines: Precision for Every Fluid

Liquid filling machines are engineered to dispense a vast array of liquid products, ranging from thin, water-like consistencies to highly viscous pastes, into various containers. The selection of the appropriate technology is largely dictated by the liquid’s unique physical properties. For applications in food, beverage, and pharmaceuticals, a hygienic design, often featuring 304 or 316 stainless steel, and Clean-In-Place (CIP) capabilities are paramount.

1. Gravity Filling Machines: The Simple Choice for Free-Flowing Liquids

These machines harness the fundamental force of gravity, allowing liquid to flow from an elevated holding tank through timed valves into containers. The duration for which these valves remain open precisely controls the dispensed volume.

Gravity filling machines are ideally suited for thin, free-flowing, non-carbonated liquids with low viscosity (typically 0-200 cP), such as water, fruit juices, alcoholic beverages, vinegar, light oils, liquid soaps, and certain chemicals or liquid medications.

Their primary advantages lie in their simplicity and cost-effectiveness, requiring fewer mechanical parts and thus lower initial investment and maintenance. They offer remarkable versatility, easily adapting to various container shapes and sizes. Furthermore, their non-invasive, gentle filling process minimizes agitation, making them excellent for foam-prone or sensitive liquids by allowing foam to dissipate naturally. With proper calibration, they achieve highly consistent fill levels, crucial for visual uniformity and customer satisfaction. However, their reliance on gravity limits their use for highly viscous or thick liquids.

2. Piston Filling Machines: Mastering Viscous Liquids and Particulates

Piston filling machines operate on a volumetric principle, employing a piston to accurately draw a predetermined volume of liquid into a cylinder, then forcefully expelling it into the container.

They are exceptionally well-suited for viscous liquids and products containing particulates, including creams, honey, jams, sauces, gels, oils, lotions, pastes, and even items with fruit chunks or seeds.

A key advantage is their high accuracy and consistency, providing repeatable, precise volumetric fills essential for regulatory compliance and minimizing product waste. Their versatility allows them to handle a broad range of viscosities and adapt to various container materials and shapes. The volumetric principle inherently minimizes product loss, contributing to cost savings. Moreover, their open cylinder design effectively handles products with large particulates without clogging, making them a superior choice for such applications. While highly versatile, extreme variations in container size might necessitate different piston sizes.

3. Pump Filling Machines: Versatility Across the Viscosity Spectrum

Pump filling machines utilize various types of pumps—such as peristaltic, gear, rotary lobe, or progressive cavity pumps—to precisely meter and transfer liquids into containers. The choice of pump depends on the liquid’s characteristics and the desired flow properties.

- Peristaltic Pumps: These operate by rollers compressing a flexible tube, propelling liquid forward without it ever contacting mechanical parts. This makes them ideal for high-value, sensitive, or highly hygienic products (e.g., pharmaceuticals, diagnostic reagents, cold-brew teas), especially for small batches and frequent changeovers. They offer superior hygiene, high accuracy (±0.5% to ±1%), and rapid product changeovers.

- Gear Pumps: A positive displacement pump, gear pumps use rotating gears to trap and push product. They are cost-effective, easy to clean, and suitable for high-volume filling of both viscous and free-flowing products.

- Rotary Lobe Pumps: Similar to gear pumps but with fewer, larger lobes, these are excellent for high-viscosity liquids and products with small to medium particulates, commonly found in dairy, personal care, and food industries. They offer hygienic solutions and high accuracy.

- Progressive Cavity Pumps: Used for extremely high-viscosity products or those with solids, due to their high output pressure.

Pump filling machines offer broad viscosity compatibility, from thin to highly viscous liquids. They maintain precise volumes and can be highly automated for various applications.

4. Overflow Filling Machines: Achieving Consistent Visual Levels

Overflow filling machines ensure that every container is filled to a consistent visual liquid level, regardless of minor internal volume variations. This is achieved by immersing nozzles into the container, allowing excess liquid to overflow back into a reservoir until the desired level is met.

These machines are best suited for low to medium viscosity liquids (up to 200 cP), particularly transparent products where aesthetic fill levels are critical (e.g., juices, water, wine, certain chemicals). They are also highly effective for foam-prone products like shampoos and cleansers, as the overflow process helps manage and dissipate foam, ensuring a consistent fill despite foaming properties.

Their primary benefits include achieving a visually uniform appearance, effective foam management, and minimal product loss as excess liquid is recirculated. They can easily accommodate non-uniform containers and are designed for quick cleaning and seamless integration into existing lines. However, they are not ideal for high-viscosity products, and the recirculation process might degrade certain sensitive liquids.

5. Vacuum Filling Machines: Gentle Handling for Delicate Products

Vacuum filling machines operate by creating a vacuum at the container’s neck, which draws liquid from a supply tank into the container. They are commonly used for oxygen-sensitive products like wine, where gentle, no-spill filling is crucial to preserve product integrity. They can also be adapted for very fine or fragile powders (as vacuum powder filling machines). Their main advantages include a gentle, spill-free filling method that protects oxygen-sensitive products, effectively removes residual air, and minimizes dust (for powders). While effective, their speed can be slower compared to other filling methods.

The detailed classification of liquid filling machines underscores that the choice of equipment is fundamentally driven by the rheological properties of the product—its viscosity, foaming tendencies, and particulate content. Gravity fillers, for instance, are limited to low viscosities, while piston fillers excel with thick or chunky products, and overflow fillers specifically address visual consistency and foam. This highlights that a one-size-fits-all approach is insufficient. The emphasis on “gentle handling” for oxygen-sensitive products further illustrates the critical need to preserve product integrity. Effective filling is a complex engineering challenge, demanding a deep understanding of both product physics and machine mechanics. An ill-suited choice can lead to substantial product waste, quality compromises, and operational inefficiencies, underscoring the critical nature of the initial selection.

B. Powder Filling Machines: Precise Dispensing for Dry Goods

Powder filling machines are indispensable for accurately dispensing dry products, which can range from free-flowing granules to fine, non-free-flowing powders. Achieving precision and consistency is paramount, particularly in regulated industries like pharmaceuticals and nutraceuticals.

1. Auger Filling Machines: Versatility for Diverse Powders

Auger filling machines, also known as screw feeders, are the most prevalent type for powders. They operate using a precisely machined auger (screw) that rotates within a hopper, discharging a measured amount of powder into the container. The fill volume is controlled by the number of auger rotations.

These machines are highly versatile, suitable for a wide array of powders, including both free-flowing (e.g., granular sugar, salt) and non-free-flowing types (e.g., talcum powder, flour, spices, coffee powder).

Their key advantages include high accuracy (often less than 1% error) for applications demanding precision. They offer precise control through adjustable auger speed and rotation, often enhanced by servo motors. Many models can be equipped with dust control mechanisms and explosion-proof features, making them safe for environments with potentially explosive dust. While versatile, they can be abrasive on certain powders, and different products or fill weights may require specific auger tooling.

2. Volumetric Cup Filling Machines: Speed for Granular Products

Volumetric cup filling machines operate by filling pre-set volume cups with powder, leveling the contents, and then discharging the product into the container.

They are best suited for free-flowing, granular powders with consistent density where exact weight is less critical than consistent volume (e.g., rice, grains, sugar, salt, nuts, beans, certain detergents).

Their main benefits include high speed (typically 30 to 80 bags per minute), simple operation, and generally lower initial and maintenance costs. They offer flexibility through adjustable cup sizes and filling speeds. However, their accuracy can be lower for powders with varying densities, making them less ideal for high-value products where precise weight is crucial.

3. Net Weight Filling Machines: Unparalleled Accuracy for High-Value Powders

Net weight filling machines achieve the highest accuracy by directly weighing the powder in the container or a weigh bucket before dispensing. This often involves a two-stage fill process (bulk and dribble) for extreme precision.

They are ideal for high-value or regulated products where precise weight is critical, including those with varying densities, viscosities, or foaming characteristics.

Their primary advantage is unparalleled accuracy (e.g., +/- 0.25% to 1%), which significantly reduces product giveaway and ensures regulatory compliance. They offer versatility across a broad spectrum of products, including liquids and solids, and maintain consistency regardless of density changes. However, they are generally slower than volumetric fillers due to the time required for precise weighing, and their initial investment is higher due to the integrated weighing components.

4. Vacuum Powder Filling Machines: Minimizing Dust and Preserving Sensitivity

Vacuum powder filling machines utilize a vacuum system to draw a precise amount of powder into the container.

They are particularly effective for very fine, dusty, aerated, or fragile powders that do not flow easily on their own (e.g., toner, certain pharmaceuticals, milk powder, flour).

Their advantages include minimizing dust generation, effectively handling difficult powders, suitability for small fill volumes, and reducing oxygen within the package, which helps preserve product quality and extend shelf life. While beneficial for sensitive powders, they can be slower than other methods and may not be suitable for all powder types.

5. Vibratory Filling Machines: Controlled Flow for Granules and Small Parts

Vibratory filling machines use vibration to fluidize and settle bulk materials (granules, powders, small mechanical parts, pills) into a weighing system, then dispense the appropriate amount into the container.

They are effective for handling sticky powders, improving uniform entry, and reducing air pockets. They are commonly used in food, pharmaceutical, and chemical industries where precise and consistent filling is essential.

Their benefits include high accuracy (with adjustable amplitude and frequency), reduced damage to product or equipment due to gentle motion, and increased throughput compared to manual processes.

The landscape of powder filling machine technology reveals a critical interplay between speed, accuracy, and cost. For instance, while net weight fillers offer the highest precision, they come with a trade-off in speed and a higher initial investment. Conversely, volumetric cup fillers provide faster, more economical solutions, albeit with less weight-based accuracy. This isn’t merely a technical choice but a significant economic consideration. High-value powders, such as pharmaceuticals, demand the precision of net weight fillers to minimize costly waste. In contrast, low-value, high-volume granular products like rice benefit from the speed and lower cost of volumetric cup fillers, where slight weight variations are acceptable. Therefore, the selection of a powder filling machine is a pivotal business decision that directly impacts profitability. Manufacturers must carefully weigh the cost of product waste (due to inaccuracy) against machine speed and initial investment, ensuring the technology aligns perfectly with the specific product’s value and production volume.

C. Pouch Packing Machines: Flexible Solutions for Modern Packaging

Pouch packing machines have seen a surge in popularity driven by their sustainability, cost-effectiveness, and consumer appeal. These machines are designed to fill and seal products into flexible pouches, accommodating a wide range of materials including polyethylene, polypropylene, laminates, aluminum foil, and paper.

1. VFFS (Vertical Form Fill Seal) Machines: Vertical Efficiency

VFFS machines take a flat roll of packaging film, form it vertically into a tube, fill it with product (granules, liquids, powders), and then seal it to create a finished package. The film unwinds, passes over a forming tube, is vertically sealed, filled, and then horizontally sealed and cut.

They are highly versatile, suitable for free-flowing products like nuts, sugar, salt, and liquids. They are extensively used across food, beverage, pharmaceuticals (tablets, capsules, syringes), personal care (creams, lotions, gels, powders), pet food, and industrial products.

Key advantages include high-speed packaging (up to 160 bags per minute) , a compact design due to vertical operation , and cost-effectiveness through optimized film usage and reduced labor. They also ensure product safety with airtight seals, extending shelf life and preventing contamination. However, they typically involve a higher initial investment and require technical expertise for operation and maintenance.

2. HFFS (Horizontal Form Fill Seal) Machines: Precision for Irregular Items

HFFS machines operate horizontally. The packaging film is fed horizontally, sealed on both sides and the bottom, the product is received through the open top, and then the pouches are sealed and cut into individual units.

They are ideal for products requiring horizontal packaging (e.g., candy, protein bars, baked goods) and are better suited for delicate packaging (e.g., frozen foods, medical devices) or irregular products (e.g., toys, parts). They can also package liquids, granules, or powders.

HFFS machines offer more precise operation than VFFS machines and are highly flexible, handling a wide range of materials. They are suitable for high-speed, high-volume packaging operations. A notable consideration is their generally larger footprint compared to VFFS machines due to their horizontal layout.

3. Premade Pouch Filling Machines: Simplified Operation for Diverse Pouch Styles

Premade pouch filling machines utilize pre-formed and pre-shaped bags, focusing primarily on the filling and sealing steps.

They are highly versatile, capable of handling liquids (beverages, sauces, oils), powders (flour, salt, spices, pharmaceuticals), granules (sugar, coffee, spices), and blocks. They accommodate a wide variety of pre-made pouch styles, including stand-up pouches, flat pouches, zipper pouches, spouted pouches, and various seal configurations (3-side, 4-side).

Their advantages include greater pouch style diversity, leading to more visually appealing packaging. They offer simplified, often fully automated, operation. They can achieve high speeds (up to 68 bags per minute) and high accuracy (e.g., ±0.1% for liquids, ±0.5% for powders). Quick, tool-less changeovers (10-30 minutes) enhance line flexibility. While offering many benefits, the cost of pre-made pouches can be slightly higher than roll film.

The distinct operational principles and ideal product applications of VFFS, HFFS, and premade pouch machines highlight that the choice of packaging format is not merely functional but strategic. The growing preference for pouch packaging, driven by its sustainability and consumer appeal , underscores this. HFFS machines offer precision for delicate or irregular items, while VFFS machines provide a compact, high-speed solution for free-flowing goods. This demonstrates how the packaging form itself can be a crucial market differentiator, influencing consumer perception, logistics, and environmental impact. Consequently, companies must consider their target market, product characteristics, and brand values when selecting a packaging format, as this decision directly informs the choice of filling machine and the overarching supply chain strategy.

D. Tube Filling Machines: Perfecting Pastes and Gels

Tube filling machines are indispensable across the pharmaceutical, cosmetic, and food industries for precisely filling and sealing creams, gels, pastes, ointments, and semi-solid products into tubes. They are designed to handle a range of product viscosities.

The process typically involves feeding empty tubes into the machine, often automatically. Tubes are held by grippers and moved through various stations for orientation, optional cleaning, and then precise product filling. For low-viscosity products, nozzles may enter shallowly, while for thicker products, they dive to the bottom and retract gradually to prevent stringing. Sealing methods vary by tube material: metal tubes are crimped, while plastic and laminate tubes are heat-sealed using hot air. Batch coding and trimming are often integrated.

These machines are compatible with various tube materials, including plastic, laminate, metal, and aluminum.

Their advantages include high accuracy (fill volume error typically below 1%) , high speed and efficiency (fully automatic machines can reach 60-120 tubes per minute) , and reduced labor requirements due to automation. They offer versatility in handling different product types, viscosities, and tube materials/sizes. Furthermore, they adhere to high hygiene standards, often featuring stainless steel construction and safety mechanisms.

The distinct sealing methods employed by tube filling machines—crimping for metal tubes and heat-sealing for plastic/laminate tubes —clearly illustrate how the physical properties of the packaging material directly dictate the sealing technology. This is not a minor detail but a fundamental engineering constraint and a critical factor for packaging integrity and product shelf life. The choice of a tube filling machine thus extends beyond merely dispensing the product; it’s about ensuring a secure and compatible seal. This necessitates a holistic consideration of the packaging process, where tube material, product characteristics, and sealing technology are interdependent.

E. Can Filling Machines: High-Speed Solutions for Beverages and More

Can filling machines are crucial for efficiently and precisely dispensing a wide array of products into cans, with a particular emphasis on beverages. They are engineered for high-speed, high-quality, and high-productivity performance.

A key focus for beverages is counter-pressure filling (also known as isobaric filling), a specialized method for carbonated soft drinks (CSD) like cola, soda water, beer, sparkling wine, and hard seltzers. The process involves:

- Can Infeed & Positioning: Cans are conveyed to the filling station, centered, and sealed.

- CO2 Purging: The cans are pressurized with CO2 to purge residual oxygen, minimizing oxygen pickup and preventing negative pressure, even for thin-walled aluminum cans.

- Equalization & Filling: After purging, equal pressure is established between the can and the product tank. The liquid valve opens, and filling commences under pressure to prevent foaming and carbonation loss.

- Level Control: Advanced systems use sensors and adjustable return air pipes to precisely control the liquid level, stopping the fill when the desired height is reached.

- De-pressurization & Can Exit: Pressure is balanced to atmospheric, and the filled can is released to the seaming machine.

The benefits of this specialized process are significant: it ensures perfect carbonation levels without fizz loss , minimizes oxygen ingress, which preserves product quality , and enables high-speed, precise filling for large-volume production.

Can filling machines streamline production, enhance product quality, and reduce waste. Industrial-scale machines can achieve capacities of up to 70,000 containers per hour (CPH).

The detailed explanation of counter-pressure filling goes beyond mere dispensing; it’s about preserving the chemical and physical integrity of carbonated beverages. The CO2 purging and isobaric pressure maintenance are direct applications of gas laws, designed to prevent CO2 escape and oxygen ingress, both of which compromise taste, shelf life, and appearance (foaming). This highlights the sophisticated engineering solutions tailored to complex product challenges. For sensitive products like carbonated drinks, the can filling machine is not just a production tool but a critical component of quality control and brand integrity. This technology directly influences the consumer experience and product stability, making the selection of such specialized equipment an integral part of product quality assurance.

F. Water Bottling Machines: Ensuring Purity and Volume

Water bottling machines are specialized bottle filling machines designed for high-speed, hygienic, and precise filling of water and other non-carbonated beverages into various bottle sizes. These machines are often integrated into “3-in-1 monobloc” systems that combine rinsing, filling, and capping functions, minimizing human contact and ensuring stringent hygiene. Due to water’s low viscosity, gravity and overflow filling methods are ideal. Advanced filling valves ensure high speed while minimizing contact between purified water and the external environment, and Clean-In-Place (CIP) capabilities are a significant advantage for hygiene.

Their advantages include high production speeds (fully automatic machines can reach 2,000-36,000 bottles per hour for small bottles, and up to 300 bottles per hour for 5-gallon bottles). Enhanced hygiene is achieved through automation and sanitary designs (stainless steel construction), reducing contamination risks. Precise control systems ensure accurate fill levels, and automation leads to cost savings by reducing labor and waste. However, they can be relatively costly to purchase, may consume substantial power, and are not suitable for solid or highly viscous products.

The evolution of water bottling machines, from manual to fully automated systems, and the integration of advanced sensors, robotics, IoT, and eco-friendly designs , reflect broader trends across the packaging industry. The emphasis on hygiene and energy efficiency is particularly pronounced in the water sector, driven by consumer and regulatory demands for purity and sustainability. This specialized area exemplifies how technological advancements are propelled by specific product needs and market pressures. Thus, the water bottling machine industry is a prime example of how filling machine technology continuously innovates to meet evolving consumer expectations for product quality, safety, and environmental responsibility, pushing the boundaries of automation and smart manufacturing.

III. Choosing Your Champion: Key Factors in Machine Selection

Selecting the appropriate filling machine is a pivotal decision that profoundly impacts operational efficiency, product quality, and overall profitability. It demands a comprehensive evaluation of numerous interconnected factors.

1. Product Characteristics: The Foundation of Choice

The nature of your product is the primary determinant. Is it water-thin, semi-viscous, or highly viscous? This dictates whether a gravity, piston, pump, or overflow filler is most suitable. Does your product contain particulates, chunks, or seeds? This would favor piston or rotary lobe pump fillers. Is it prone to foaming? Overflow fillers or bottom-up filling nozzles are crucial. Is it oxygen-sensitive, fragile, or requires sterile conditions? Consider vacuum fillers or peristaltic pumps. For powders, the stability of density influences volumetric filling accuracy; net weight fillers are better for variable-density powders.

2. Container Type and Size: Matching the Vessel

The machine must seamlessly integrate with your containers. What material are they made of—glass, plastic, metal, flexible pouches, or laminate tubes? Each requires specific handling and sealing mechanisms. What are their shapes and size ranges (minimum/maximum volume, height, diameter)? While most machines handle a wide range, extreme variations might necessitate custom solutions or different piston sizes. The opening size (wide vs. narrow mouth) also influences nozzle selection.

3. Production Volume and Speed: Meeting Demand

Your target output (bottles/cans/pouches per minute or hour) is critical. This directly determines the required level of automation—manual, semi-automatic, or fully automatic—and the number of filling heads. Are you looking for batch production or continuous high throughput? Semi-automatic systems suit batches, while fully automatic systems are designed for continuous, high-volume operations.

4. Budget and Return on Investment (ROI)

Beyond the initial purchase price, a comprehensive budget analysis must consider the total cost of ownership (TCO). This includes operational costs (labor, energy), maintenance, spare parts, and future upgrade potential. A seemingly cheaper machine might incur higher long-term costs due to inefficiencies, product waste, or inability to scale.

5. Hygiene and Regulatory Compliance

For industries like food, beverage, and pharmaceuticals, stringent hygiene and safety standards (e.g., GMP, FDA, CE) are non-negotiable. Look for stainless steel construction (304 or 316L) and designs that facilitate easy cleaning, often with Clean-In-Place (CIP) capabilities.

6. Customization and Future Scalability

Consider suppliers who offer customization options and machines that can be upgraded or adapted to future product lines or anticipated growth in demand. This foresight can prevent costly re-investments down the line.

7. Supplier Support and After-Sales Service

The importance of responsive technical support, comprehensive training, ongoing maintenance, and readily available spare parts cannot be overstated. A reliable supplier partnership ensures smooth operations and minimizes downtime.

The criteria for selecting a filling machine extend far beyond the initial purchase price, encompassing operational costs (labor, waste), maintenance, regulatory compliance, and future adaptability. A seemingly more affordable machine might ultimately lead to higher long-term expenses due to inefficiencies, product wastage, or an inability to scale. The emphasis on hygienic design and compliance underscores the potential liabilities and market access issues that can arise from failing to meet these requirements. Therefore, making a truly informed decision about a

filling machine necessitates a comprehensive Total Cost of Ownership (TCO) analysis, weighing long-term operational benefits and risks (e.g., regulatory fines, product recalls) against the initial capital outlay. This shifts the procurement mindset from simply seeking the lowest price to prioritizing the highest value and lowest risk over the machine’s entire lifecycle.

Conclusion: Empowering Your Production with the Right Filling Technology

Choosing the right product filling machine is a complex yet profoundly critical decision that underpins the success of any manufacturing operation. It necessitates a meticulous alignment of specific product characteristics, container types, and production objectives with the optimal filling technology and level of automation. An informed choice in this arena translates directly into heightened efficiency, superior product quality, minimized waste, and substantial long-term cost savings.

Navigating the diverse landscape of filling machinery demands deep industry knowledge and technical acumen. We invite you to partner with us, leveraging our extensive experience and unwavering commitment to delivering innovative, customized packaging solutions. Contact our experts today to discuss your unique requirements and discover how our cutting-edge filling machines can elevate your production capabilities, ensuring your sustained success in a fiercely competitive market.

Comments