Feeding systems are the heart of any automated packaging or production line – they deliver your product to the machines that wrap, fill, or label it. In simple terms, a feeding system is a mechanical (often automated) solution that measures, sorts, and transfers items into packaging equipment. These systems include conveyors, vibratory bowl feeders, hoppers, robotic feeders, and more. By ensuring a continuous, well-organized flow of products into your machinery, feeding systems eliminate bottlenecks, boost throughput, and maintain consistent quality. As XuebaPack explains, automated feeding systems “ensure that products arrive synchronized, continuous and in the right position to be packaged” – in other words, they keep your line running smoothly without manual intervention.

Feeding systems go by many names – you might hear them called feeder lines, feeder systems, or parts feeders in manufacturing settings. What they all have in common is the goal of automating the material handling step so machines can focus on packaging. In a smart factory or Industry 4.0 environment, feeding systems often include advanced features like machine vision, robotics, or flexible conveyors. But even a basic feed conveyor or bowl feeder can transform efficiency: as one packaging expert notes, conveyor-fed lines “can do a lot to improve packaging efficiency and automate packaging lines”.

In this article, we’ll explain what a feeding system is and why it’s important for your business. We’ll cover the main types of feeders (from feed conveyor systems to vibratory bowls), the key benefits they deliver, and how they contribute to higher productivity and lower costs. Whether you run a food packaging plant, a pharmaceutical line, or any production facility, understanding feeding systems will help you boost efficiency and ROI.

What Is a Feeding System?

A feeding system is the automated equipment that supplies items to your packaging or production machines. In packaging, this means moving products (like bottles, pouches, snacks, bolts, etc.) from the production line or bulk storage into the packaging machinery in a controlled way. For example, a conveyor belt might carry snack bars into a wrapping machine, or a hopper might feed granules into a filling nozzle. These systems can be manual, semi-automatic, or fully automated (automatic feeding). Today’s high-volume plants rely on automated feeding to minimize human handling and maximize speed.

According to industry experts, an automated feeding system is “a set of equipment and mechanisms designed to receive, sort, group and transfer products… to a flowpack wrapping machine, without manual intervention”. In other words, it’s a self-contained line of equipment (conveyors, feeders, robots, etc.) that makes sure each product reaches the next machine correctly aligned and at the right time. The goal is a synchronized, continuous flow of goods. As XuebaPack explains, “The automatic feeding system is an indispensable part of packaging machinery. It can realize the efficient, accurate and continuous supply of materials”, which greatly improves automation and production efficiency.

At its core, a feeding system does three things: 1) it makes products available to the packaging machines; 2) it orients or aligns them as needed; and 3) it times their delivery so the packaging equipment runs without interruption. By taking over repetitive tasks like sorting and positioning, feeding systems free workers from manual loading. They also reduce errors (misfeeds, jams, misaligned products) that can happen with hand-feeding, ensuring higher consistency. In a modern facility, a well-designed automated feeding system becomes the backbone of production, enabling fast, reliable packaging cycles around the clock.

Common Types of Feeding Systems

Feeding systems come in many varieties, each suited for different products and speeds. Here are some of the most common feeding components and systems:

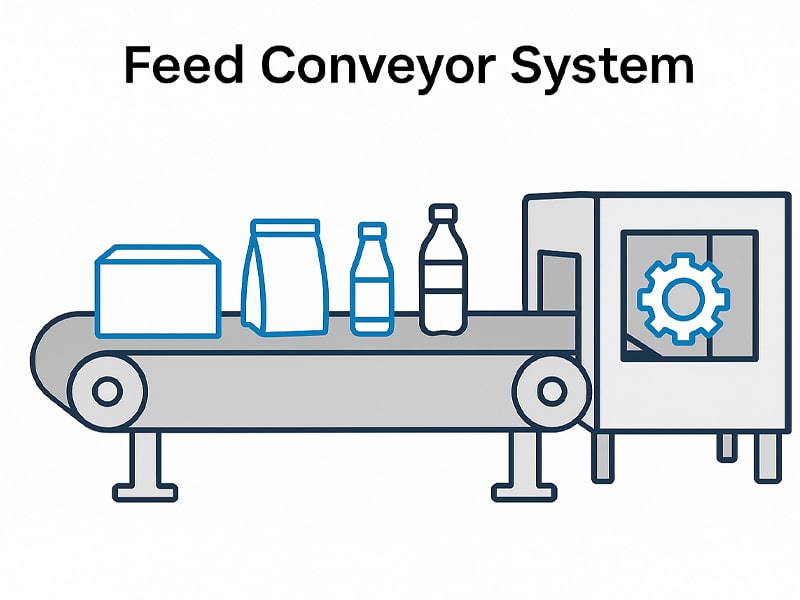

- Feed Conveyor Systems: These use belts, rollers or chains to carry products continuously into a machine. Conveyors are hugely versatile – they can transport almost anything (boxes, bags, bottles, snack bars, etc.) at various speeds. For example, long belt conveyors can shuttle pallets or large items, while narrow belt conveyors feed individual products into wrappers. Conveyors are integral to many packaging lines because they are simple, scalable, and can be adapted to your layout. They “can be mounted in a variety of ways,” including floor, ceiling, or even vertical layouts, making efficient use of space.

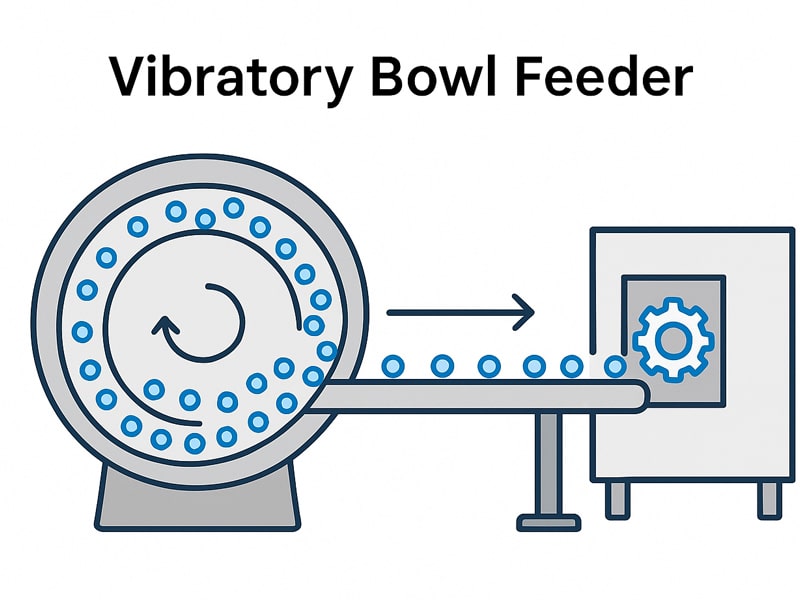

- Vibratory Bowl Feeders: These are round, vibrating dishes that sort and orient small parts (like caps, tablets, or candies) before feeding them one by one onto a conveyor or directly into a machine. Vibratory feeders use gentle vibration and gravity to move products up a spiral track, where parts are singulated in a consistent orientation. They are excellent for high-speed handling of small, loose items. For instance, cap aligners on bottling lines or tablet feeders in blister packaging often use vibratory bowls. They ensure precise alignment and high throughput (often several hundred items per minute) with minimal human effort.

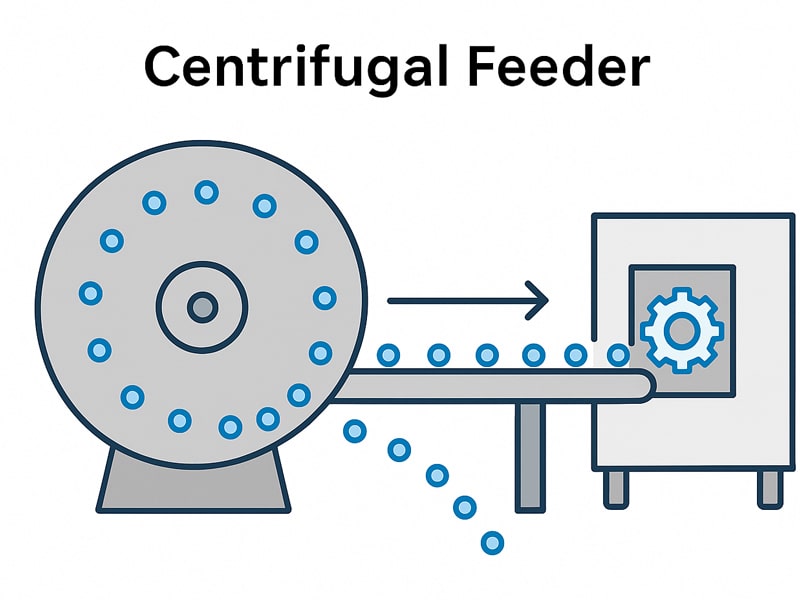

- Centrifugal Feeders: These high-speed feeders spin products outward on a wheel or disk, ejecting them onto a conveyor or rail at high rates. Because of the centrifugal force, these systems can handle thousands of parts per minute. They are ideal for very high-volume operations with small parts (like candies, screws, or washers). A centrifugal feeder can rapidly accelerate and orient parts gently, increasing throughput while still protecting delicate items.

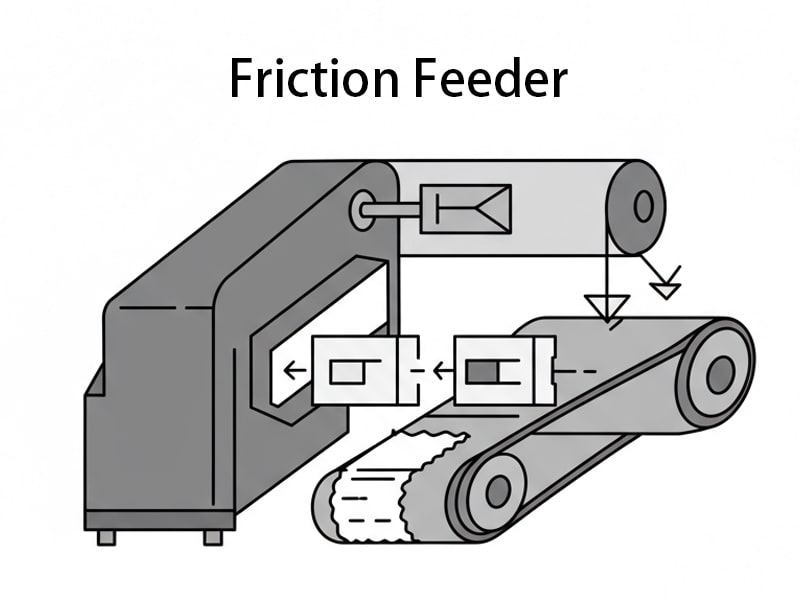

- Friction Feeders: Common in labeling or flat packaging lines, friction feeders use moving belts or wheels to advance flat products (like pouches, cartons, or envelopes) one by one. They rely on friction against a drive roller to pull in sheets or pockets. Friction feeders can handle printed materials, cards, or pouches, and often integrate with printers or coders. They allow precise batch counting and timing of items. By combining a feeder belt with an indexing mechanism, a friction feeder can deliver exactly the right number of items to the next station with high accuracy.

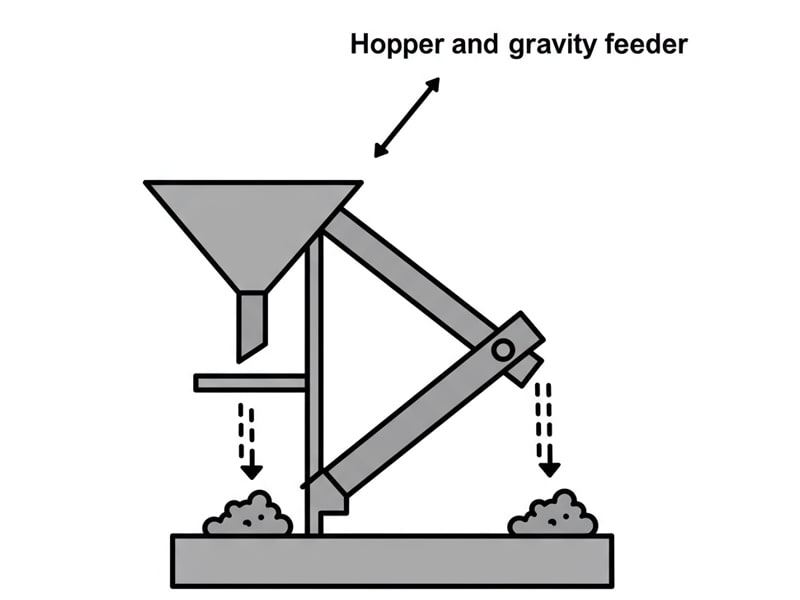

- Hopper & Gravity Feeders: Some bulk materials (like granules, powders, or discrete parts) use a hopper – a large bin that holds the material – to feed items into the line via gravity. For example, a bulk sugar hopper might feed sugar into multiple weighing scales. Hoppers help ensure a continuous supply by buffering production. A vibratory hopper can even agitate the contents to prevent bridging. These systems are often used in industries like chemicals, grains, or cement, where controlled flow of raw material is critical. They are usually paired with weigh scales or mixers.

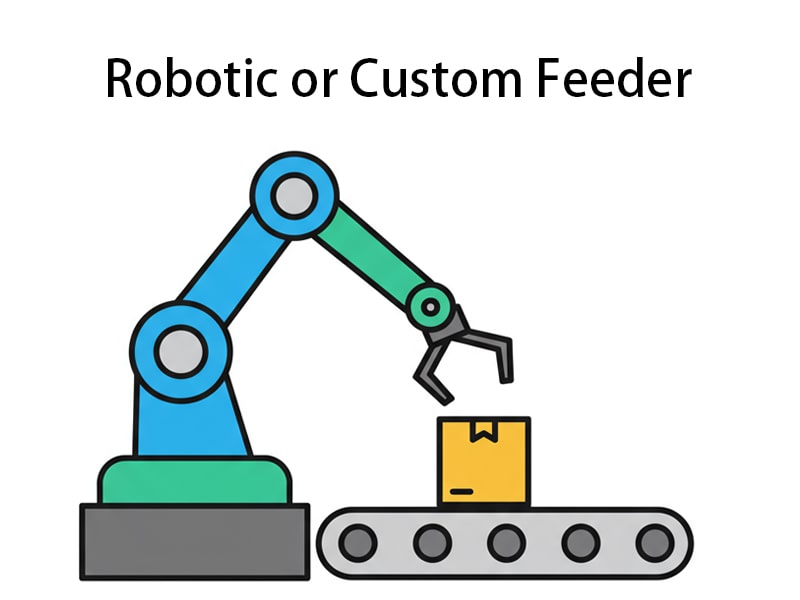

- Robotic or Custom Feeders: Advanced lines may use robots or custom feeders for unique needs. For instance, a robotic arm with vision can pick items from a bin and place them on a conveyor for very fragile or irregular products. Custom feeders combine different technologies (robots + bowl feeders + conveyors) for complex shapes. For example, feeder robots in automotive or electronics assembly can select tiny parts and feed them precisely. These systems offer ultimate flexibility for handling multiple product types with minimal manual setup.

Each of these feeding solutions serves the same purpose: deliver product into your machines efficiently. Often, a single line will use multiple feeders in sequence – for example, a vibratory bowl might orient caps onto a small conveyor, which then feeds bottles into a capping machine. The choice depends on your products and speed. Importantly, most of these systems can be fully automated: once the feeder is loaded, it runs continuously with little operator input. In practice, “automated feeding systems… handle a wide variety of products of different sizes, textures, shapes or fragility”, making them invaluable for modern packaging lines.

Feed Conveyors: The Workhorse of Automated Feeding

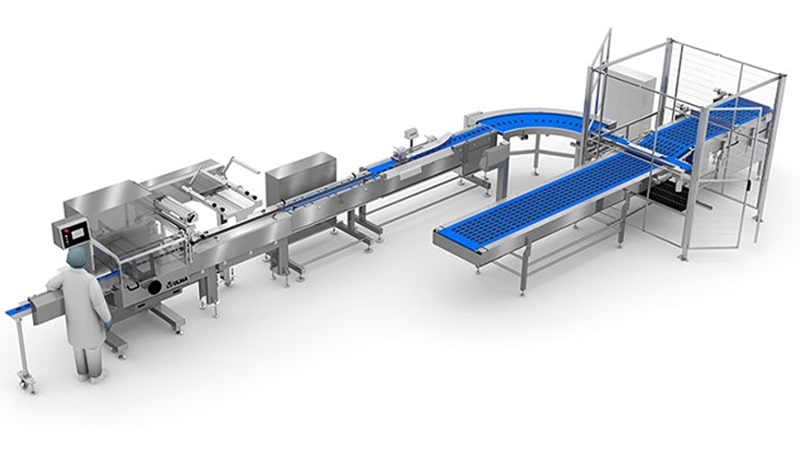

One of the most visible elements of a feeding system is the feed conveyor or feed conveyor system. A feed conveyor is simply a moving belt or chain that transports items from one point to another. In packaging, feed conveyors move products from upstream equipment (like filling machines or indexers) into the packaging machine (like a flow-wrapper or cartoner).

Conveyors are incredibly important because they provide a continuous flow of product. Conveyor systems can be a hugely beneficial and necessary addition to many packaging processes. They save labor (no workers need to carry or push product manually) and reduce handling errors. For example, replacing a manual trolley with a conveyor “can help you cut back \[on labor costs] without sacrificing safety or quality,” since “conveyor systems are more efficient than forklifts, carts, or manual transport and require fewer people to move an item”. This means your team can focus on high-value tasks rather than shuffling packages.

Beyond labor savings, conveyors increase throughput. Because they move continuously, you can pack many more items per hour than by hand. Constant conveyor movement means that you can significantly increase the number of delivered items, helping factories hit their production quotas. In practice, a well-set-up conveyor can carry 24/7 loads – even enabling automated night shifts. Modern automated feeders (including conveyors) can handle high volumes of parts quickly and with high levels of precision, supporting… increased efficiency and throughput.

Conveyors also improve consistency and product handling. By establishing a standard flow rate and spacing, they “are vital for establishing consistency and standardization in your packaging process,” which “decreases the risk of error”. This means far fewer jams and reworks. For fragile or irregular items, conveyors can be fitted with gentle guides or tables, ensuring each unit arrives safely at the next station. They can be programmed to change speed, direction, or even height on the fly, giving you flexibility to match output to demand. In short, a feed conveyor system ties your line together: it synchronizes upstream production with packaging machines and keeps everything moving at a steady, optimal pace.

Key takeaway: A feed conveyor or belt is a core part of many feeding systems. It automates material movement, saving labor and floor space, and boosts output by enabling continuous packaging operations. In any packaging business, adding or optimizing conveyor feed can yield immediate efficiency gains.

|

| Packaging lines with conveyors and feeding systems |

Why Automated Feeding Matters for Your Business

Automated feeding systems are not just a convenience – they’re a strategic investment. Here’s why they are crucial to any manufacturing or packaging business:

- Higher Throughput & Efficiency: By automating the feeding process, you keep your packaging machines running at full speed. Feeding systems eliminate idle time waiting for new product. As industry sources point out, a continuous automated feed “ensures a continuous supply of parts… minimizing downtime and enhancing overall efficiency”. In practice, this means hitting production targets and getting more product out the door. Whether you make cookies, capsules, or cables, feeding systems make sure every machine is fed and working. Automated feeders can “handle high volumes… with high levels of precision, supporting the desire to increase efficiency and throughput”.

- Reduced Labor and Costs: Manual feeding is labor-intensive. It requires workers to load each machine, which limits speed and increases payroll. A feeding system turns labor hours into simple oversight. For example, instead of three people hand-loading cartons, one operator can monitor a feeder that continuously loads the machine. This can cut labor costs significantly. Conveyors and automated feeders require fewer people to move an item. Modern systems significantly reduce the need for human intervention, reducing the risk of introducing errors while increasing throughput. The bonus is that you can run lines longer (even 24/7) because you’re not limited by staff availability, boosting capacity during peak demand. Less manual handling also means fewer worker injuries from repetitive lifting, improving safety.

- Improved Quality and Consistency: Automation brings repeatable precision. A feeding system will align or pack items the same way every cycle, which prevents misfeeds or skewed packages. This consistency maximizes quality. Conveyors establish standard spacing and flow, which decreases the risk of error. On the smart factory side, automated feeders with sensors or vision systems can even inspect parts as they feed, ensuring only “good” products reach the line. The result is less waste from faulty or damaged goods. By feeding parts accurately, these systems reduce scrap and rework – an immediate cost saving. In other words, better feeding means better final products.

- Flexibility and Scalability: A good feeding system can handle different products with minimal downtime. Many feeders are adjustable for size and speed changes. For instance, a vibratory feeder bowl may switch molds to feed different parts, or a conveyor can adjust its belt guides for wider packages. This flexibility lets you adapt quickly to new SKUs or custom orders. Custom automated feeders can integrate various technologies to handle different shapes and sizes, enhancing overall operational efficiency. Modern feeders can be reprogrammed or retooled to handle multiple parts, supporting batch production and quick changeovers. This agility is vital in competitive markets where product lines change often.

- Scalable Growth & ROI: Feeding systems contribute directly to your bottom line. By increasing throughput and reducing waste, they typically pay for themselves over time. Rotech (a marking equipment supplier) lists “increased throughput and efficiency” and “reduced waste” as key advantages of automated feeders. With higher output, you produce more salable units per hour. With fewer misfeeds or jams, you waste fewer materials. And with lower labor costs, your margins improve. These gains mean your initial investment in feeding hardware is recouped via higher profits and capacity. Moreover, adding automation can increase your facility’s value and appeal to customers who demand reliability. In sum, feeding systems are not just machinery – they’re ROI-driving assets.

- Meeting Industry Standards & Industry 4.0 Goals: Finally, feeding systems help you stay current. Many industries (food, pharma, electronics) have strict hygiene, traceability, and efficiency standards. Automated feeding supports these by providing clean, controlled product handling. For example, a stainless-steel feeder bowl is easier to wash than manual bins. Automated logging of feed counts aids quality control. On a broader scale, industry thought leaders tie feeding systems to Smart Factory initiatives. According to experts, modern automated feeders – especially those with vision and robotics – are “essential to smart factory efforts” aimed at higher efficiency, agility, and quality. In other words, adopting automated feeding aligns you with Industry 4.0 goals of flexibility and data-driven production. Keeping up with this technology can give your business a competitive edge in the digital age.

In short, a well-designed feeding system makes your entire line faster, smarter, and more cost-effective. It ensures machines never starve for product and frees your team from repetitive work. With production running more smoothly, you can scale up output, improve quality, and ultimately grow your business. As one industry leader concludes: “The automatic feeding system is an indispensable part of packaging machinery…improving the automation and production efficiency of the entire production line.”

How to Implement the Right Feeding System

Choosing and integrating a feeding system depends on your specific process and products. Here are a few high-level considerations:

- Analyze Your Product and Volume. Start by identifying your product characteristics: Is it solid, fragile, liquid? Does it come in bags, bottles, or free-flowing form? Also consider your production rate (e.g. units per minute). These factors determine feeder type. For example, high-volume small parts may need a centrifugal feeder, whereas bulk powders may use a hopper + auger system. SFXB recommends considering three key factors: production requirements, product nature, and presentation. (See image below for an overview.)

- Match Feeder Type to Product. Use conveyors for rigid or bulk items (boxes, jars, cases). Use vibratory bowls for loose, small parts that need orientation (caps, tablets, candies). Use hoppers for powders or grains. For flat products (pouches, sachets), a friction feeder is ideal. If your product changes shape or you require very high speeds, consider flexible feeders with vision systems or robots. In practice, many lines use a combination: e.g. a hopper drops parts into a vibratory feeder, which then places them on a conveyor. The key is ensuring continuity: feed devices must keep up with the slowest machine in your line.

- Automate Wherever Possible. The trend is clear: automate feeding to reduce manual steps. Look for systems that can automatically adjust and run with minimal staff. Today’s automated feeders may include sensors, servo drives, and even AI vision to adapt to slight variations in product. This reduces changeover time and errors. For instance, modern feeders can be quickly reprogrammed when you switch products. If you’re not running 24/7, a loading hopper or reservoir can allow one operator to load bulk product once and run many hours without intervention.

- Integration and Safety. Work with suppliers to ensure the feeding system integrates smoothly into your existing line. Guards, sensors, and interlocks should be part of the design for worker safety. Also consider how the feed system will interface with your control system: many feeders can communicate machine status (jam, empty, etc.) to a central PLC. This lets you monitor flow and maintain traceability.

- Scalability. Choose a system that can scale. If you anticipate growth, plan for higher speeds or multiple lanes. Many conveyors and feeders are modular – you can add lanes or extend length as needed. This future-proofs your investment.

By carefully planning your feeding solution – and using the right combination of conveyors, feeders, hoppers or robotics – you create an uninterrupted, efficient supply of material. This frees up your human resources, maximizes your machines’ uptime, and ultimately boosts your business performance.

Conclusion

A feeding system might sound like a simple part of your line, but it’s actually a game-changing element of modern manufacturing. The right feeding system ensures that every product is measured, oriented, and delivered to the packaging equipment just in time. This synchronization is what drives efficiency, reduces waste, and lowers costs. Whether you’re packaging food, beverages, pharmaceuticals, or fasteners, investing in automated feeding can yield immediate benefits: higher throughput, consistent quality, and lower labor costs.

In today’s competitive market, businesses can’t afford avoidable downtime or errors. An automated feeding system plugs those gaps, making your packaging line faster and more reliable. As industry experts note, these systems are indispensable for achieving “continuous, efficient, and accurate” production. They are also a key enabler of smart factory initiatives, aligning your operations with Industry 4.0 goals of flexibility and cost-effectiveness.

Ultimately, a feeding system is an investment in your bottom line. By choosing the right feeders and conveyors, you ensure that your production never stalls and your team can focus on innovation rather than manual work. In short, a well-engineered feeding system will transform your packaging business – boosting productivity, improving product quality, and giving you a critical edge in the market.

Frequently Asked Questions (FAQ) About Feeding System

1. What is a feeding system and how does it work?

A feeding system automates the delivery of products (e.g., bottles, pouches, small parts) into packaging or processing machines. It typically includes conveyors, feeders, sensors, and hoppers to sort, orient, and transfer items without manual input. These systems ensure products are correctly positioned and timed for efficient continuous packaging.

2. What are the main types of feeding systems?

Common feeding system types include:

● Vibratory bowl feeders (for orienting small parts)

● Feed conveyors (belt, roller, chain conveyors)

● Hoppers and gravity feeders (bulk materials)

● Robotic feeders and 3D bin-picking (complex shapes or robotic integration)

3. How is a feed conveyor system different from a feeder?

A feed conveyor is a moving-belt or roller system transporting items continuously. A feeder provides controlled, rate-based delivery (e.g. vibratory or screw feeders). Feeder systems often use conveyors to transport product once oriented.

4. What are the advantages of automated feeding systems?

Key benefits include:

● Higher throughput and reduced downtime

● Lower labor costs by eliminating manual loading

● Improved consistency and quality

● Enhanced safety and hygiene

● Scalability and flexibility for multiple product lines

5. Which industries use feeding systems?

Feeding systems are critical in:

● Food and beverage

● Pharmaceuticals

● Consumer goods (snacks, cosmetics)

● Electronics and automotive (for small parts)

● Manufacturing and packaging lines

6. What safety and sanitation considerations apply?

● Food-grade conveyors should use stainless steel, easy-clean designs to meet FDA/USDA/dairy 3-A standards

● Safety guards, sensors, and proper ergonomics are essential to prevent injuries

7. How do I choose the correct feeding system?

Consider:

● Product type (size, shape, fragility)

● Production volume and conveyor speed

● Layout and spatial constraints

● Hygiene and safety standards

● Flexibility and automation needs (e.g., robotic feeders)

8. Can feeding systems handle multiple products?

Yes. Systems can be modular or reprogrammable, allowing quick changeovers between products or batches—ideal for flexible or multi-SKU manufacturing.

9. What is the ROI on implementing a feeding system?

Automated feeding often pays back quickly by boosting output, reducing labor and waste, improving consistency, and enabling longer step-free production runs. ROI analysis should compare cost vs savings and increased throughput.

10. What future trends are shaping feeding systems?

Modern trends include:

● Integration of vision-guided robotics (3D bin-picking) for flexible handling

● Smart, sensor-based systems linked to Industry 4.0 platforms

● Ongoing improvements in sanitation, hygiene, and automation efficiency

| References: | |

| 1. | The Demand for Smart and Efficient Conveying Systems ——Retrieved from:FoodEngineering |

| 2. | Automatic Feeding System for Packaging Machine ——Retrieved from:Lintyco |

| 3. | Behind the Machines: The Importance of Feeders in Manufacturing ——Retrieved from:www.researchgate.net |

| 4. | The Benefits of “Automated Feeding Systems” ——Retrieved from: LinkedIn Insight |

| 5. | Design of Feeding System of Automatic Rod Packing Machine ——Retrieved from:https://sensors.myu-group.co.jp/sm_pdf/SM2987.pdf |

Comments