Doypack packaging (or doypack bags) refers to stand-up pouch technology: flexible pouches engineered to stand upright for product display and handling. These bags are made from laminated films (plastic, foil, paper, etc.) and can include features like resealable zippers, tear notches, or built-in spouts for pouring. Often called stand-up pouches or doypack pouches, doypacks are essentially self-contained packages. For example, one source notes that doypacks “solve all of the packaging needs for a single product without the need for extras such as labels, plastic framing or padding”. This means the pouch itself can serve as a complete package.

Key Types and Features of Doypack Pouches

Manufacturers offer many doypack formats and options to meet specific product needs. For example, common doypack variants include:

● Spouted pouches (spout bags): Stand-up bags with an integrated spout (often on top or side) for pouring liquids. These are often called spout bags and require compatible filling machines.

● Valved bags: Pouches with one-way degassing valves (commonly used for coffee and other foods) to release gases while maintaining freshness.

● Flat-bottom pouches: Pouches with square or gusseted bottoms for extra stability on shelves.

● Handle pouches: Pouches with punched or attached handles to ease carrying.

● Resealable pouches: Bags equipped with zipper/grip seals or tear notches to allow multiple openings.

● Windowed pouches: Pouches with clear windows so consumers can see the contents.

● Material variations: Options like aluminum foil, kraft paper, PET film, or fully recyclable/compostable laminates.

Each doypack is tailored to its contents. For instance, a pouch for liquids might use a polyethylene spout, whereas a coffee pouch typically uses a foil barrier. These pouches are fully customizable in size and graphics, turning the doypack bag itself into a marketing tool. As one packaging expert notes, doypacks offer advantages in preservation, practicality and marketing, helping create distinctive packaging that strengthens brand image.

Advantages and Applications of Doypack Packaging

Doypack pouches offer many advantages:

● Improved Preservation: Multi-layer films (including foil barriers) keep products fresh longer. Resealable zippers and caps let consumers store products between uses. In practice, these features reduce spoilage and waste.

● Compact Transport: Doypacks are lightweight and can be shipped flat, saving space. This efficiency reduces fuel use during transport. SPS Packaging notes that doypacks “are lightweight, flexible and easy to store and transport,” meaning they save space and fuel throughout their lifecycle.

● Eco-Friendly Options: Flexible pouches often use less raw material than rigid containers. Many doypacks today are made with recyclable or biodegradable films. For example, some are printed on recyclable PET or compostable materials. When collected properly, doypacks can join the recycling loop or circular economy efforts, minimizing landfill waste.

● Convenience & Branding: Stand-up pouch bags are user-friendly. Their ability to stand upright and include resealable tops or spouts makes them practical for consumers. At the same time, the pouch provides a 360-degree printable surface for graphics, enabling strong brand messaging. As one source explains, investing in custom doypack designs helps improve product appeal and communicate a brand’s quality to customers.

● Versatility: Doypacks can carry solids, powders, pastes, or liquids. They are used in a wide range of industries. For example, doypacks are found in cosmetics (face masks, creams) and food sectors (snacks, nuts, spices). They are also used for beverages (coffee, tea, juices), pet food (treats, kibble), nutritional supplements (protein powders), and even specialty items like gardening seeds or electronics accessories. Small brands can start with compact fillers to serve niche markets, while larger brands scale up to high-speed pouch lines as needed.

● Labor & Cost Efficiency: Automated doypack machines cut labor needs and scrap. Precision filling heads prevent spills, meaning more product yield per run. The automation enables higher throughput and 24/7 operation, improving return on investment.

Industries using doypack packaging include: cosmetics, food and snacks, beverages, pet products, healthcare supplements, and more. This breadth reflects doypack’s ability to meet storage and freshness needs across many product types.

Doypack Packaging Machines

To efficiently produce these pouches, factories use automated doypack packaging machines. A DoyPack Pouch Packaging Machine (often just called a doypack filling machine) automatically fills premade stand-up pouches with product and then seals them. These machines are designed for versatility: they can handle powders, granules, solids (e.g. cereals, candies) and even liquids. Many of these machines are CE-certified and use PLC touchscreen controls, reflecting industry standards for safety and automation. For instance, Exaktapack describes doypack machines as “suitable for dry products, granules, powder and liquids,” built from stainless steel with PLC or touchscreen interfaces.

There are two main approaches:

● Premade Pouch Fillers: These machines pick empty doypack bags from a magazine, open them, and then fill and seal each pouch. Modern models are robust (often IP65 stainless steel) and feature touchscreen control panels. They may operate on a rotary or indexing principle; for example, a rotary machine might process four-seal or four-side pouches in one cycle. Speeds vary – many rotating pouch fillers run around 50 bags per minute.

● Vertical Form-Fill-Seal (VFFS): These systems create the pouch from a continuous film roll, fill it, and then cut and seal it in one vertical line. VFFS is common when forming the bag inline is desired, offering flexibility in pouch size. (It’s less common for spouted designs, which are usually premade.)

Many pouch machines also offer Quick Format Changes: advanced systems allow electronic adjustments for different pouch dimensions, enabling rapid switches between sample packs and larger retail pouches without lengthy downtime. Additional options often include vibrating product feeders, integrated checkweighers, labeling stations, hole punches, vacuum or gas-flush units, and inkjet coders. In practice, a packaging line might include a doypack filling machine followed by a labeling machine and an automated case-packer, delivering ready-to-ship packages with minimal labor.

Spout Pouch Filling Machines and Applications

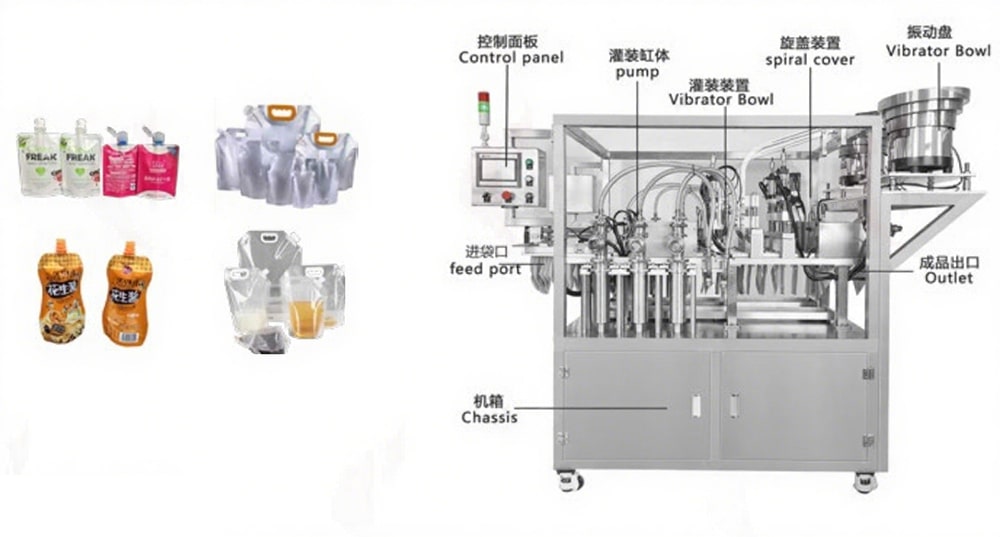

Specialized machines exist for spout bags – doypacks with a molded pouring spout and screw cap. A Spout Pouch Filling Machine is specifically designed to handle these bags. It aligns each pouch by its open spout, fills in the liquid product, and then seals the spout with its cap. As one packaging guide explains, “a spout pouch filling machine is specialized equipment designed to fill and seal spouted pouches with precision”, maintaining speed, accuracy, and consistency.

Spout doypacks have surged in popularity because they combine convenience with efficiency. They save shelf space and shipping volume compared to rigid bottles, and their spouts make dispensing easy. For example, one source notes that spout pouches “reduce storage space, cut shipping costs, and are eco-friendlier than traditional packaging,” while making pouring convenient and helping preserve product freshness. In other words, these pouches boost customer satisfaction and meet modern sustainability goals. Typical applications include:

● Beverages: Juices, smoothies, energy drinks, etc., in convenient single-serve packs.

● Sauces & Condiments: Ketchup, mayonnaise, mustard, honey – squeezable with a cap.

● Dairy & Food: Yogurts, baby food purees, soups.

● Oils & Liquids: Cooking oils, herbal tinctures, cleaning liquids.

● Personal Care: Shampoos, lotions, liquid soaps in travel-size pouches.

● Others: Products like laundry detergent, nutritional gels, and liquid fertilizers.

How Spout Pouch Packaging Machines Work

Spout pouch filling and sealing follows an automated sequence. A typical process might be:

1. Pouch Feeding: Empty spout pouches (with caps on a separate tray) are loaded into the machine. High-end lines may use automatic bag pickers or flipping devices for fast loading.

2. Pouch Positioning: The machine orients each pouch under the filling nozzle, ensuring the open spout is properly aligned. Sensors or guides confirm correct placement.

3. Filling: A precision pump (often a gear or piston pump) doses the exact volume of product into the pouch’s spout. The filling heads are designed to avoid drips or overflow.

4. Capping: Once filled, the spout is closed with its cap. Servo-driven capping heads torque the cap to the right tightness, ensuring a leak-proof seal.

5. Optional Finishing: Additional modules may label the pouch, print dates or batch codes, or vacuum-pack the filled bag for longer shelf life.

6. Inspection & Discharge: Filled pouches undergo a final check (weight or seal inspection) and are then discharged for case-packing or shipping.

7. Quality Check & Packing: Many lines include an automated weight check or vision inspection to ensure fill accuracy and seal integrity. After inspection, finished pouches are collected into cartons or placed onto pallets by automated case packers.

These machines can be very high-speed. For example, certain designs achieve 50–120 bags per minute depending on the model. Labeled diagram of a spout pouch filling machine (top view): 1) Pouch feeder, 2) Rotary pouch table, 3) Filling nozzles, 4) Capping unit. Each of these advanced machines is designed with hygiene and reliability in mind (often fully stainless steel, IP65-rated). They allow manufacturers to fill, seal, and label pouches continuously with minimal human intervention.

Sustainability and the Circular Economy

The packaging industry is increasingly focused on sustainability. Compared to rigid containers, doypack pouches can dramatically cut material use and waste. Many manufacturers now use mono-material laminates to simplify recycling. Indeed, pouch makers like SPS emphasize circular economy goals: by 2027, they aim for all flexible packaging to be fully recyclable or reusable. Because doypacks keep products fresh longer and can be made from recyclable films, they contribute to waste reduction. As SPS notes, a single doypack (with resealable features or spout caps) means products last longer and the pouch itself can be widely recycled. In practical terms, using doypack packaging can reduce a product’s carbon footprint and align with consumer preferences: NielsenIQ’s 2023 report found that 92% of consumers value sustainable packaging when choosing brands.

Conclusion

Doypack packaging is a versatile, efficient solution that meets modern manufacturing and sustainability needs. Lightweight, resealable pouch bags protect contents, save space, and appeal to eco-conscious consumers. When combined with automated filling equipment – from DoyPack Pouch Packaging Machines to dedicated Spout Pouch Filling Machines – manufacturers create high-speed production lines that maintain product quality. For example, lightweight doypacks significantly cut shipping fuel and storage space, reducing logistics costs.

In summary, doypacks deliver “preservation, practicality and marketing” advantages. By understanding pouch design and integrating advanced machinery, businesses can build efficient, eco-friendly packaging lines. In practice, companies like Guangzhou SFXB (Xuebapack) exemplify this trend: We offer turnkey automated doypack filling lines (for sauces, condiments and beverages) using precisely this technology. Properly leveraging doypack technology and modern filling machines ensures product quality, reduces waste, and meets consumer expectations – making these systems a smart, future-oriented choice for many companies. Thorough testing and supplier collaboration are crucial to successful implementation.

| References: | |

| 1. | Wikipedia – Stand-up pouch (Doypack) |

| 2. | Environmental impacts of plastic packaging of food products – ScienceDirect (2022) |

| 3. | Eco-efficiency analysis of an innovative packaging production: case study – Springer Nature |

| 4. | Sealester – Environmentally-friendly materials for doy‑packs |

Comments