Cap sorting machines are a cornerstone of modern automated packaging. By handling the tedious job of separating and orienting bottle caps, these machines ensure that caps are fed into capping equipment in a continuous, correct orientation. In high-volume lines (e.g. beverage, food, pharmaceutical, cosmetics), this automation speeds up production and reduces manual labor. As one cap sorter manufacturer explains, the system works alongside automatic capping machines to put caps on bottles “more efficiently,” taking over what would otherwise be a manual, error-prone task. By aligning each closure correctly before application, cap sorting systems streamline the capping process and enhance productivity. In short, precise cap feeding minimizes downtime and maximizes line efficiency, making cap sorters essential equipment in fast-paced packaging plants.

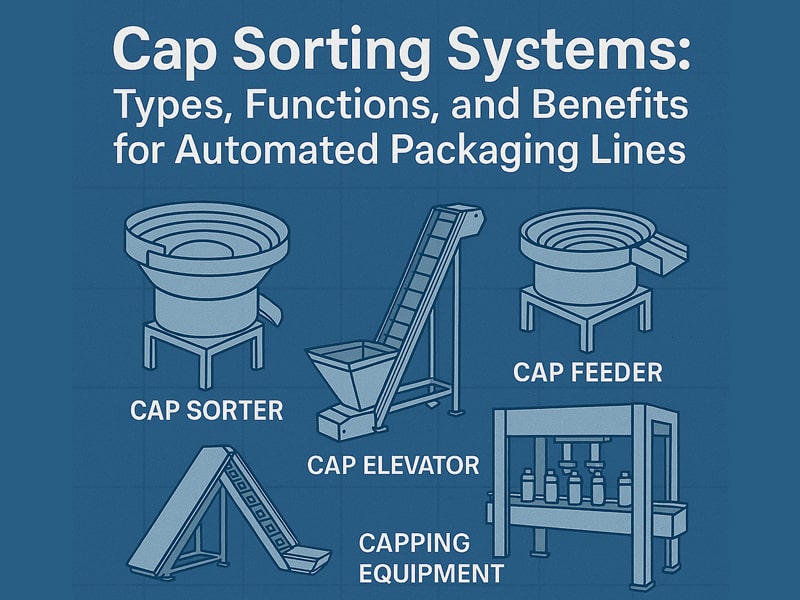

Automated cap feeding equipment goes by many names – “cap sorters,” “cap feeders,” or “cap elevators” – reflecting its functions. SFXB, for example, calls its solutions “waterfall cap sorting systems” or “cap elevator sorter feeders,” emphasizing the vertical lift and feeding action. At their core, these machines collect loose caps from a hopper, orient them consistently, and deliver them one by one to the capping head or chute. A leading equipment supplier notes that cap sorters (or “cap orienters”) are built to handle various cap types and align them “with precision” before the capping stage. Typical systems include a bulk hopper to hold caps, an elevator or cleated belt to raise them to the proper height, and an orienting mechanism (like a bowl or rotating wheel) that lines up the caps as they proceed toward the capper. This setup ensures a steady, ordered flow of caps. The cap elevator lifts caps to the required height, ensuring a steady flow into the cap feeder, and then the sorting machine “orient the caps” for the next step. All of these functions – storing caps, elevating them, orienting them, and metering them out – combine to feed the capping equipment without interruption, thereby improving overall line throughput.

Types of Cap Sorting Machines

Cap sorting machines come in several designs to match different production needs and cap types. The main categories include rotary (centrifugal) sorters, vibratory bowl feeders, and elevator (waterfall) sorters, among others. Each type uses a different method to orient and feed caps. Below are the key machine types:

● Rotary/Centrifugal Cap Sorters: These systems use rotating bowls or wheels. Caps are accelerated by centrifugal force along the bowl’s perimeter, often aided by air jets or specially shaped tracks, to orient them. A rotary (centrifugal) sorter uses “combinations of centrifugal force, compressed air and creative geometry to align caps” and then feeds them singly to the capping machine. In practice, a rotary cap sorter spins caps around a disc or drum; malformed or upside-down caps roll back to be recirculated, while correctly oriented caps exit the chute. Such sorters are especially suited to high-speed applications. For instance, XuebaPack notes that a horizontal centrifugal cap sorter will “quickly separate and align caps, ensuring a rapid and continuous flow”. Centrifugal sorters can handle a wide range of cap shapes; SFXB highlights their “Centrifugal Cap Sorting Bowl” which is effective for flat, non-flat, and specialty caps at high speed. Because these bowls rely on velocity rather than vibration, they tend to be relatively quiet and ideal when throughput is paramount.

● Vibratory Bowl Feeders: Vibratory or bowl feeders are extremely common. A vibratory bowl sorter uses controlled mechanical vibrations to move caps along a spiral track in a bowl-shaped feeder. As the caps travel up the spiral, guide rails and gravity flips them so they all exit the bowl in a uniform orientation (for example, all top-side up or down). These systems are highly versatile:Vibratory cap bowl can handle “flat, non-flat or specialty caps” of many shapes (such as sports caps or cone caps) simply by changing the bowl insert. The design typically includes interchangeable plates or tools for different cap geometries. In operation, caps dropped into the bowl are gently agitated and sorted automatically. For example, a detailed description of a vibratory cap sorter explains that the bowl “puts lids into order, so that all caps are facing down or up,” after which they are automatically loaded onto bottles. This controlled, consistent flow of caps “saving labor cost and improving work efficiency”. Vibratory cap sorters “effectively separate and orient caps, ensuring a consistent flow for downstream processes”. These bowls are especially popular because they can be fitted for nearly any plastic, aluminum, or metal cap and are easy to reconfigure.

Figure: A vibratory bowl feeder for bottle caps. The bowl vibrates to “separate and align caps,” ensuring a smooth, single-file flow out of the feeder.

|

● Elevator/Waterfall Sorters: In this design, caps are lifted vertically and then fed downwards. Typically, a cleated or belted elevator picks caps from a low hopper and raises them to the height of the feeding chute. Often called a waterfall cap sorter, this system uses gravity and a sloped, cleated belt to orient the caps. A waterfall sorter uses inclined cleated belts and the ‘center of gravity’ principle to properly align caps, then handing them off via a chute. In other words, caps enter a tall, narrow cleated belt (as shown below), climb to the top, and drop one by one in a single file. This is highly efficient for bulk feeding. For example, SFXB advertises its Cap Sorting Elevator that can handle flat caps up to 110 mm, “carry up the universal, cleated belt and \[blowing] down into the capper chute”. This vertical approach is also compact: it requires little horizontal space but supplies the capping machine at the correct height. Cleated elevators are generally simple and durable, making them a common, economical choice.

Figure: A cap elevator sorter with a cleated belt. Caps in the base hopper (bottom) are lifted up a vertical belt; the belt’s cleats carry them to the discharge chute for orientation and feeding.

Automatic Bottle Cap Unscrambler For Capping Machine Work with filling machine and capping machine to realize automated production. |

● Pocket or Drum Sorters (less common): Some lines use rotating drums or “pocket” sorters. These have a drum with cavities (pockets) that capture individual caps; as the drum rotates, caps are flipped and then released in the correct orientation. We did not find a particular citation here, but these are sometimes used for metal caps or lids in food canning. They work on the same principle of mechanical orientation but differ from bowls by using discrete pockets.

Each type can be further customized. The choice of sorter often depends on the required speed, the cap material, and the existing line layout. Importantly, most modern sorters are made of stainless steel (304 SS) to meet hygiene standards, and may include clear covers or enclosures for safety and cleanliness.

Functions of a Cap Sorting Machine in an Automated Line

In an automated packaging line, the cap sorting machine’s core function is to deliver a steady, correctly-oriented stream of caps to the capping machine. These machines handle every cap that will be applied, performing a few key steps:

● Bulk feeding and elevation: The sorter begins with a bulk hopper that receives loose caps (often from jugs or boxes). The machine lifts these caps to the correct height for feeding. As one description notes, the sorter “is made up of a hopper (where the caps are loaded) and an elevator (which moves the caps up to the machine that puts them on the bottles)”. This removes the need for an operator to manually climb and feed caps.

● Orientation: Once elevated, caps are oriented into a uniform position. The machine flips or aligns caps so that, for example, screw caps are right-side-up or snap caps are facing correctly. SFXB emphasizes that its advanced sorters “orient the caps, preparing them for the next stage of production”. By precisely positioning each closure relative to the container neck, the sorter “streamlines the capping process”. In practical terms, misaligned or upside-down caps are returned to the hopper or recycled, while properly oriented caps continue forward.

● Single-file feeding: The sorter then meters out caps one by one (or in the needed count) to the capper. Typically a chute or conveyor delivers caps to the cap applicator. This single-file feed ensures the capping head can place each cap without backups or misfeeds. The design often includes sensors or blow-back nozzles to reject defective caps or to keep spacing consistent, though specific designs vary by manufacturer.

● Continuous operation: By automating the feed, the sorter ensures that the capping machine never runs out of caps unexpectedly. The machine may include a level sensor to alert when bulk caps are low. An automated cap feeder “realiz automated production” and makes the line faster and easier by “cutting down on the need for people to do this task by hand”.

Overall, the cap sorting system acts as a conveyor of oriented caps. It replaces manual scooping and placing of caps, allowing the entire capping section to run at high speed. By ensuring that every cap is correctly aligned and fed at the proper rate, the sorter minimizes jams and errors. As one machine builder summarizes, its cap sorter ensures caps “are properly aligned for downstream processes such as capping”. This precise alignment and feeding function is critical for maximizing uptime on an automated line.

Key Benefits of Cap Sorting Systems

Cap sorting machines offer many tangible advantages for manufacturers. Some of the key benefits include:

● Increased Productivity and Efficiency: Automating the cap feed significantly boosts line speed. With a sorter in place, caps are delivered at rates often exceeding manual capability. Suppliers note that automated sorters allow the capping machine to run at its full design speed, with minimal delays. In practice, one vibratory feeder description touts that the machine can be adjusted to achieve high production (1000–10000 bottles/hour) with a very high “qualified rate”. In short, lines with good cap sorters consistently reach higher throughput.

● Labor Savings and Lower Operating Costs: By taking over a repetitive task, cap sorters reduce labor requirements. Fewer operators are needed to replenish caps, and one operator can monitor multiple machines instead of manually placing caps. This also improves ergonomics and safety by reducing the need to climb ladders or handle parts near moving equipment.

● Reliable Accuracy and Quality: Proper orientation means fewer misfeeds and less downtime. Caps are less likely to jam or be applied incorrectly. Every cap is “precisely positioned” before application, ensuring consistent torque and seal quality. This is especially important for tamper-evident caps or threaded closures that must be aligned perfectly. Many systems are highly repeatable, so product quality is more consistent batch after batch.

● Versatility and Compatibility: Modern sorters can handle a wide variety of cap types and sizes. Whether you have plastic screw caps, aluminum flip-tops, snap-on cosmetic caps, or bulk metal lids, there’s usually a sorter configuration for it. For example, SFXB notes that its machines can be equipped with “elevator sorters, vibratory bowl, centrifugal bowl, pocket sorter” to fit “any kind of cap”. The vibratory designs work with “various cap types, including screw caps, snap-on caps, or press-on caps,” covering plastic, metal, and specialty closures. This flexibility lets one factory run different products (and caps) on the same system with minimal changeover. Even geometry variations – tall sports caps vs. shallow lids – can often be handled by changing bowl tracks or guides.

● Hygienic, Durable Design: Especially in food, beverage, and pharmaceutical plants, cleanliness is vital. Cap sorters are typically built of stainless steel (often 304 SS) and are designed for easy cleaning. As one vendor explains, their sorter’s stainless construction offers “strong corrosion resistance, making it easy to maintain and clean”. Many have smooth finishes and may be enclosed or CIP-capable. Using a sorter also keeps caps contained rather than spilling them on the floor, improving cleanliness of the line. In regulated industries, these hygienic features help satisfy GMP or FDA requirements.

● Reduced Downtime and Maintenance: Automated sorters generally run continuously without much adjustment once set up. SFXB highlights that their waterfall/elevator sorters are “designed for years of hassle-free operation, offering easy maintenance”. Quick, toolless changeovers between product runs also save time. For example, SFXB notes that modern sorters allow “simple and efficient container and cap transitions” without lengthy downtime. By preventing blockages and providing a steady feed, cap sorters also reduce unplanned stops on the line.

In summary, a properly chosen cap sorting system can dramatically improve line efficiency, consistency, and safety. Manufacturers consistently find that a good sorter pays for itself by boosting throughput, lowering labor costs, and ensuring higher-quality capping.

Applications Across Industries

Cap sorting systems are used in virtually any industry that requires capping bottles, jars, or containers. Typical applications include:

● Beverage: Soft drinks, bottled water, beer, juices, dairy, and alcoholic spirits. Cap sorters are ubiquitous on beverage filler-capper lines to handle plastic or metal caps at high speed. They keep up with rotary filling machines for high-cpm production.

● Food: Jars of sauces, condiments, baby food, etc. Sorters feed snap-on lids and screw-on caps in food plants. The hygienic stainless design is especially important here.

● Pharmaceuticals: Bottles of pills, syrups, supplements. Cap sorters handle child-resistant and tamper-evident caps. Strict cleanliness rules mean sorters must be easy to sanitize (stainless steel construction).

● Cosmetics and Personal Care: Bottles and jars of creams, lotions, shampoos, etc. Sorters orient flip-top or screw-on cosmetic caps. The ability to change colors and sizes quickly is valuable since many products run shorter batches.

● Chemical and Household Products: Bottles of cleaning liquids, motor oil, pesticides, etc. The Federal Manufacturing catalog notes that its sorters serve lines for water bottles, agricultural chemicals, and other free-flowing liquids. Sturdy design handles harsher environments and sometimes large closures.

● Other Specialty Packaging: For example, medical device containers, laboratory reagent bottles, or food tubs. If a cap or lid needs to be oriented for a press or spot-seal machine, a sorter can assist.

In fact, many cap sorter manufacturers explicitly call out these industries. Guangzhou XueBapack notes use of cap sorters in “food, medicine, and cosmetics” factories, where they “help these industries speed up their packaging lines, save money on labor, and keep things moving smoothly”. Similarly, equipment suppliers like Federal Mfg. highlight applications from beverage to agrichemicals. The key point is that any line with hand-fed capping can benefit from a cap sorter. When high speed or labor savings are priorities, adding a cap sorting system is a common choice across sectors.

How to Select the Right Cap Sorter

Choosing the proper cap sorter requires matching the machine to your production needs. Key factors include:

● Production Speed: Determine your required throughput (caps per minute). For very high-speed lines (400 CPM and above), you may need a heavy-duty centrifugal sorter or a high-capacity elevator. For lower speeds, a standard vibratory bowl may suffice. For example, SFXB notes that for speeds over 400 CPM or very large caps, they recommend robust Zalkin waterfall or centrifugal sorters.

● Cap Type and Size: Consider the material (plastic, metal, etc.), geometry (flat, tall, ribbed), and size range of your caps. Some sorters are optimized for flat, shallow caps, while others handle taller or asymmetrical caps. Make sure the machine can accommodate your largest cap (SFXB’s elevator handles up to 110 mm by default). If you frequently change products, look for a versatile design (vibratory bowls often swap inserts; waterfall sorters may have adjustable guides).

● Container and Line Layout: Assess how the sorter will fit. If floor space is limited, a waterfall-style vertical elevator might be best (it’s “space-efficient,” as Zalkin points out). If you have horizontal space, a large vibratory bowl might be an option. Also decide whether the sorter needs to be turret-mounted (on the capper itself) or as a stand-alone feed.

● Changeover and Maintenance: For multi-product lines, quick changeover is vital. SFXB emphasizes toolless or easy changeovers. Look for features like adjustable chutes, simple guide changes, and readily available spare parts. Durable stainless construction and proven components will reduce long-term maintenance.

● Hygienic Requirements: In food or pharma, sanitary design is essential. Choose machines with sealed electronics, easy-clean surfaces, and possibly CIP (clean-in-place) capability. As mentioned, many sorters use 304 stainless steel for corrosion resistance.

● Vendor Support and Integration: Work with reputable suppliers who can test the sorter with your caps and containers. Many vendors will run sample tests or loan out their machines for trials. Also, ensure the sorter can interface with your existing filling/capping equipment (mechanical mounting, controls integration, sensors). Some companies offer plug-and-play capping systems where the sorter and capper are matched.

● Budget and ROI: Finally, consider cost versus benefit. Higher-end sorters (especially very high-speed centrifugals) cost more, but they pay back by speeding up the line and cutting labor. Calculate potential labor savings and increased throughput to justify the investment. A well-chosen sorter often pays for itself quickly on a busy line.

By carefully evaluating these factors, you can select a cap sorter that fits your line. As SFXB suggests, ensure the system is “engineered to work together” with your capper for seamless operation. The right sorter should become a reliable partner in your packaging line, not a bottleneck.

Conclusion

Cap sorting systems are a critical component of automated capping lines in many industries. They reliably take bulk caps from a hopper, orient them uniformly, and feed them into capping equipment with minimal human intervention. The result is faster production, reduced labor costs, and fewer errors. Modern sorters (elevator, waterfall, vibratory, or rotary) can handle a wide variety of cap styles and are built for easy cleaning and maintenance. By understanding the types and functions of cap sorting machines, manufacturers can choose a solution that “streamline\[s] production, reduce\[s] errors, and increase\[s] overall efficiency”. In today’s competitive market, investing in the appropriate cap sorter is an investment in productivity and product quality. Prospective buyers should carefully match the sorter to their line speed, cap type, and sanitation needs, consulting experienced suppliers as needed. With the right cap sorting system in place, a packaging line will run smoother and faster—delivering a clear return on investment over time.

Frequently Asked Questions (FAQs)

1. What is a cap sorting machine?

A cap sorting machine is a device that organizes and orients bottle caps for application in packaging lines.

2. How does a cap elevator function?

A cap elevator transports caps from a lower level to the sorting mechanism, facilitating continuous operation.

3. Can cap sorters handle different cap sizes?

Yes, many cap sorters are adjustable to accommodate various cap sizes and types.

4. What industries benefit from cap sorting systems?

Industries like food and beverage, pharmaceuticals, and cosmetics utilize cap sorting systems for efficient packaging.

5. Are cap sorting systems customizable?

Many manufacturers offer customizable options to fit specific production needs.

6. How do I maintain a cap sorting system?

Regular cleaning and inspection ensure optimal performance and longevity.

7. What is the difference between vibratory and centrifugal sorters?

Vibratory sorters use vibrations for movement, while centrifugal sorters rely on spinning motion to orient caps.

8. Can cap sorting systems be integrated into existing lines?

Yes, most systems are designed for seamless integration with current packaging equipment.

9. What is the typical lifespan of a cap sorting system?

With proper maintenance, these systems can operate efficiently for several years.

10. How do I choose the right cap sorting system for my needs?

Consider factors like cap type, production speed, and integration requirements when selecting a system.

| References: | |

| 1. | “Graphical Analysis of Bottle Caps Feeding in a Vibratory Bowl Feeder”–Chitransh Singh&M. L. Chandravanshi –Retrieved from: ResearchGate |

| 2. | “A Review on Vibratory Bowl Feeder”–Chitransh Singh&M. L. Chandravanshi –Retrieved from: ResearchGate |

| 3. | ”Graphical Analysis of Bottle Caps Feeding in a Vibratory Bowl Feeder”–R. Jain, S. Choudhary –Retrieved from:IJISET |

Comments