Bottling Line Machines: Definition and Key Components

Bottling line machines are integrated systems used in beverage, water, pharmaceutical, and consumer-goods factories to automate the filling, capping, labeling, and packaging of bottles. In essence, a bottling line machine (also called a bottle filling line) is “the backbone of any bottling process,” designed to handle the complete sequence of filling, sealing, and packaging bottles. These production lines can fill water, juice, soda, oils, syrups or even tablets into bottles on a large scale. By automating tasks that would otherwise be manual, bottling lines significantly increase output, accuracy, and hygiene, while reducing waste and labor costs.

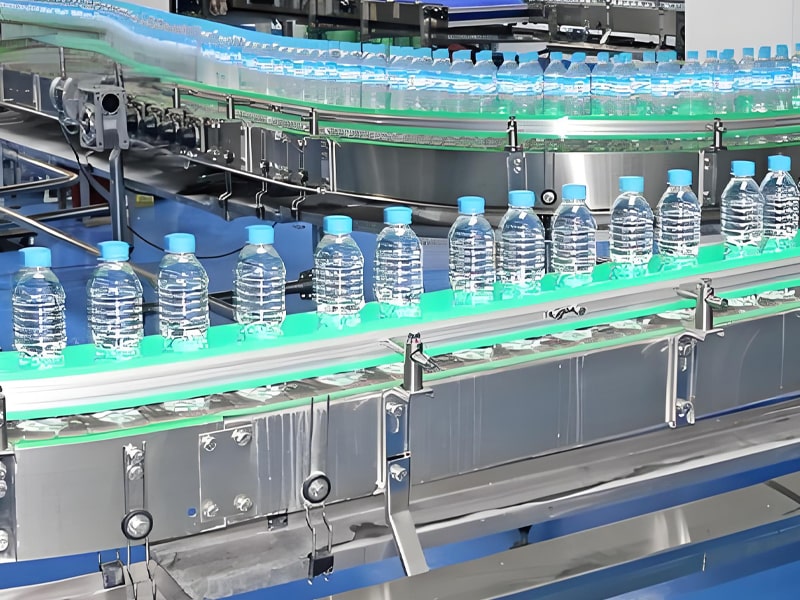

Figure: A modern Inline bottling line combining a bottle unscrambler and filler with conveyors and pumps. Machines like these automate each step in the water and beverage packaging process.

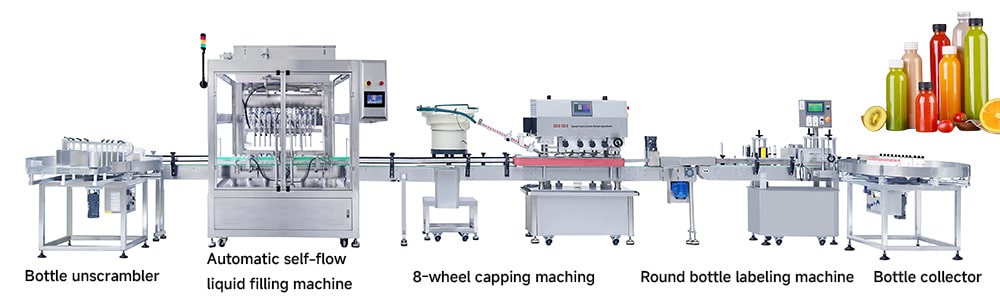

Bottling line machines typically include several core modules or stations:

- Bottle Unscrambler (Sorter): Feeds empty bottles onto the line in the correct orientation.

- Bottle Cleaner/Rinser: Uses air or water jets to wash and sterilize bottles before filling.

- Bottle Filling Machine: Precisely dispenses liquid or product into each bottle. For example, water lines often use gravity fillers optimized for low-viscosity fluids.

- Capper (Closure Machine): Applies and tightens caps or corks to sealed bottles, ensuring airtight closure.

- Labeler: Applies adhesive labels or sleeves to bottles for branding and regulatory information.

- Packaging/Grouping: Some lines include cartoning or shrink-wrapping machines to bundle filled bottles for shipping.

- Conveyor System: Moves bottles steadily from one station to the next. Conveyors are adjustable to handle different bottle sizes and maintain a smooth flow.

- Control Panel: A central PLC-based interface lets operators set fill volumes, speeds, and synchronize all modules. This “brain” coordinates timing between fillers, cappers, and other modules.

- Sensors & Inspection: Photoelectric sensors detect bottle presence and position (preventing empty fills), while vision systems and metal detectors ensure quality and safety.

Each module works in unison to form a cohesive bottling system. As one expert notes, “a complete bottling line typically integrates multiple components to handle each step of the process” – from unscramblers and rinsers to fillers, cappers, sealers and labelers. For example, a commercial water bottling line might first clean bottles with air rinsers, then fill them with a water filling machine, automatically cap them, and finally apply labels before packaging. In high-speed lines, rotary indexing machines allow many bottles to be filled simultaneously under multiple nozzles, greatly boosting output.

How Bottling Line Machines Work

Modern bottling lines are often fully automated and use advanced controls. The typical workflow is as follows:

- Bottle Feeding: Empty bottles arrive on a conveyor. An unscrambler or bottle sorting machine lines them up and orients them.

- Cleaning/Rinsing: Bottles pass through an air or water rinser that removes dust and contaminants. This step is critical for consumable products (water, juice, pharmaceuticals) and ensures hygiene.

- Filling: The bottles move to the filling station. Depending on the product, different filler technologies are used:

- Gravity fillers for thin, still liquids (e.g. drinking water).

- Overflow/Pressure fillers for carbonated or viscous beverages.

- Piston or pump fillers for thicker liquids like syrups or lotions.

- Vacuum fillers can inject an inert gas layer for beverages sensitive to oxygen.

Each bottle is positioned under a fill nozzle, and the precise volume is dispensed. Sensors ensure the nozzle only fills when a bottle is correctly in place, preventing spills.

- Capping: Immediately after filling, an automatic capper secures a cap or cork on each bottle. Capping heads torque caps to the right tightness to avoid leaks.

- Sealing (Optional): Some products require foil seals or shrink bands for tamper evidence.

- Labelling: The capped bottles continue to a labeller, which applies stickers or wraps labels uniformly.

- Packaging: Finally, filled and labelled bottles are grouped and packed (for instance, by shrink-wrapping or in cardboard cartons) and palletized for shipping.

Inline vs. Rotary: Many bottling lines use inline (monoblock) machines, where bottles move continuously under a linear filler, capper and labeler. However, rotary machines (as shown above) are used for high-speed operations – multiple bottles are filled in parallel by rotating turntables, greatly increasing throughput.

Types of Bottling Lines and Machines

Bottling lines are customized by industry and product:

- Water Bottling Lines: Designed for high purity, these lines include specialized bottle water filling machines and sanitation systems. They often use air rinsers and gravity fillers to maintain water taste.

- Beverage (Soft Drink/Juice) Lines: Equipped for carbonated liquids, using counter-pressure fillers to preserve carbonation. Lines for juices or teas may include pasteurization or mixing units.

- Wine and Spirits Lines: Feature gentle fillers and corkers or screw-cap cappers. Wine lines often include vacuum filling and negative-pressure corking to protect flavor.

- Pharmaceutical/Food Lines: Use stainless-steel, sanitary components. Fillers for syrups or liquid drugs may include tablet fillers or inductive sealing machines for foil seals.

Each line can be semi-automatic (requiring operators to place bottles or caps) or fully automatic. Automatic systems can run tens of thousands of bottles per hour. As one manufacturer notes, fully automatic lines “fill, cap, label, and package bottles with various liquid products” with minimal manual work.

Specialized Filling Technologies

Key differences in bottling machines arise from the product and container:

- Gravity vs. Pressure Fillers: Gravity fillers (often for still water) simply let liquid flow into bottles; pressure fillers handle carbonated or foaming liquids.

- Volumetric vs. Level Fillers: Volumetric machines measure an exact quantity into each bottle (important for precise dosing), whereas level fillers fill to a visual line on the bottle. Overflow pressure fillers are common for consistency.

- Inline vs. Rotary: Inline fillers process bottles sequentially on a line; rotary fillers use a rotating table to fill many bottles simultaneously. Rotary machines have higher speed but are more complex and expensive.

- Linear (Conveyor) Fillers: Some lines use linear indexing – bottles move stepwise on a conveyor under each machine (rinser, filler, capper) – combining precision with moderate speed.

The choice depends on production volume, bottle size, and budget. Manual or semi-auto machines exist for small batches, but most commercial facilities use fully automated lines to minimize labor and maximize output.

Benefits of Bottling Line Machines

Implementing a bottling line machine (or a full bottling line) offers many advantages:

- High Efficiency & Speed: Automated filling and capping massively increase production speed (thousands of bottles per hour).

- Consistent Accuracy: Precision fillers and sensors ensure each bottle contains the exact same volume, improving product consistency and reducing overfills.

- Labor Savings: Automated lines reduce the need for manual labor, cutting costs and human error. Even complex tasks like handling caps or labeling can be mechanized.

- Enhanced Hygiene: In food and beverage production, sanitary design and automated rinsers uphold strict cleanliness standards. Closed machines and CIP (clean-in-place) systems minimize contamination.

- Quality Control: Many lines include automatic inspection (e.g. fill-level detectors, metal detectors, leak tests) to catch defects.

- Scalability: Machines can be configured for different bottle sizes or upgraded with additional modules (like extra labelers or packagers), making it easy to expand capacity.

- Reduced Waste: Precise filling and capping reduce spillage and spoilage. For example, calibrated pumps dispense exact liquid amounts, minimizing product loss.

- Regulatory Compliance: Equipment can be designed to meet industry standards (FDA, CE) for materials and traceability. Automated data logging aids in audits.

In short, a bottling line machine streamlines the entire packaging process. As industry sources summarize, a well-designed line “maximises efficiency, reduces labour costs, minimises errors, and enhances overall productivity”. These benefits are why even small beverage makers often invest in complete bottling lines – the consistent production quality gives a competitive edge.

Choosing and Maintaining Bottling Equipment

When selecting a bottle filling line, manufacturers should consider:

- Production Needs: Required output (bottles/hour), bottle shapes/sizes, product characteristics (carbonation, viscosity).

- Automation Level: Fully automatic (high speed, less labor) vs. semi-auto (lower cost, more manual work).

- Quality & Reliability: Brand reputation matters – reliable machines minimize downtime. Look for stainless steel construction and CE/FDA certification for food/beverage lines.

- Flexibility: Machines with quick changeovers can handle multiple bottle formats, which is useful for companies with varied product lines.

- Total Cost: Consider the long-term value. Automated systems are pricier upfront but can yield significant ROI through labor savings and efficiency.

Once installed, bottling lines require regular maintenance and cleaning. Many lines use CIP (clean-in-place) systems that sterilize fillers and pipes without disassembly, crucial for water and beverage safety. Routine calibration of sensors and mechanical parts keeps accuracy high. With proper care, bottling machines can run reliably for decades.

Conclusion

A bottling line machine (or bottle filling line) is not a single gadget but an entire production system for packaging bottled products. It combines conveyors, fillers, cappers, and other modules to transform empty bottles into ready-for-sale products at industrial scale. By automating each step – washing, filling, sealing, labeling and more – these lines ensure high speed, precision and quality control. Whether for bottled water, soda, wine or pharmaceuticals, choosing the right bottling line equipment is critical to meet safety standards and meet market demand efficiently.

Manufacturers consider factors like product type, line speed, and hygiene requirements when investing in bottling equipment. In all cases, a well-designed bottling line machine yields clear benefits: faster throughput, consistent fill accuracy, reduced labor, and better overall production yield. As the beverage and packaging industries continue to evolve, modern bottling lines increasingly incorporate smart controls and automation to stay ahead. For any company producing bottled products, understanding the capabilities of bottling line machines is essential – it’s a key driver of productivity and product quality in liquid packaging operations.

FAQs About Bottling Line Machine

What is a bottling line machine?

A bottling line machine, or bottle filling line, is an integrated production system that automates the entire process of cleaning, filling, capping, labeling, and packaging bottles. It handles a continuous flow of bottles using modules like rinsers, fillers, cappers, labelers, conveyors, and control systems, ensuring high-speed and consistent output across various industries—from water and beverages to oils, chemicals, and pharmaceuticals.

What is the difference between inline and rotary bottling line machines?

Inline (or monoblock) bottling lines move bottles sequentially through each stage—rinse, fill, cap, label—in a straight line. Rotary machines, by contrast, employ spinning turntables to fill multiple bottles simultaneously, offering much higher throughput. Inline systems are simpler and more cost-effective for moderate-volume needs, while rotary setups are suited for large-scale, high-speed operations.

Can a bottle filling line handle different types of liquids?

Absolutely. Bottling line equipment can be tailored to accommodate a wide range of liquids—from low-viscosity water and carbonated beverages to thick oils, syrups, and even chemicals. The key is selecting appropriate filling technologies: gravity or overflow for still liquids, counter-pressure or piston fillers for foaming or viscus products, and vacuum or volumetric systems for precision dosing.

How easy is it to change bottle sizes on a bottling line machine?

Modern bottling line machines are designed for flexibility. Many offer tool-less adjustments like power height movements, knobs, or preset “recipes” on touchscreen interfaces, enabling quick format changeovers. This adaptability makes it straightforward to switch between different container types and sizes with minimal downtime.

What level of automation should I choose—semi-automatic or fully automatic?

The right level depends on your production goals:

● Semi-automatic lines are cost-effective and simple, suited for smaller batches or varied production runs.

● Fully automatic systems offer faster speeds, less labor, and higher throughput—ideal for high-volume bottling. Many modern systems are also modular and upgradeable, enabling incremental automation as demand grows.

How should I choose the right filling method?

Consider the product’s properties:

● Gravity filling is great for thin, still liquids like water.

● Overflow or pressure filling works well for carbonated beverages.

● Piston or pump filling suits viscous products.

● Volumetric fillers deliver a precise quantity, whereas level fillers fill to a consistent visual mark. Match the method to your product’s viscosity, packaging, and batch precision needs.

What are the main benefits of a bottling line machine?

Key advantages include:

● High-speed, consistent production.

● Accurate fill volumes and reduced waste.

● Lower labor costs and minimized errors.

● Enhanced hygiene through automated cleaning (e.g., CIP systems).

● Better quality control via sensors and inspections.

● Scalability and flexibility for varying bottle formats.

● Improved regulatory compliance and traceability.

What are best practices for maintaining a bottle filling line?

To ensure long-term reliability and uptime:

● Use CIP (Clean-in-Place) systems for regular sanitation without disassembly.

● Schedule periodic calibration of sensors and nozzles.

● Clean or replace worn/ clogged components.

● Monitor and adjust valve timing and pressure to maintain filling accuracy.

● Provide operator training and set up preventive maintenance plans to detect issues early (e.g., inconsistent fill levels or flow supply interruptions).

Is it possible to customize bottling line equipment for specific needs?

Yes. Most manufacturers offer customized bottling line solutions tailored to your exact product, bottle design, output volume, automation level, and hygiene requirements. Customizations can include special fillers, material choices (e.g., stainless steel for sanitary needs), layout adjustments, or additional modules like inspection systems or alternative cappers.

What safety features should a bottling line include?

Modern bottling lines should incorporate:

● Emergency stop buttons at accessible points.

● Sensor-based guards and interlocks to prevent access to moving parts.

● Automated shut-off in case of malfunction.

● Compliance with relevant safety and electrical standards.

● Clear operator training to maintain safety during routine operation and maintenance.

| References: | |

| 1. | Wikipedia – “Bottling line” |

| 2. | Global Bottling Line Machinery Market – The Future of High Speed Packaging ——Retrieved from:Stellar Market Research |

| 3. | Wikipedia –”Packaging Machinery“ |

| 4. | Liquid Filling Lines Overview ——Retrieved from: Yundufilling |

Comments