The High-Stakes World of Modern Beverage Production

In the fiercely competitive landscape of the global beverage market, success is measured in milliliters and milliseconds. Consumer demand for variety, quality, and novelty is relentless, while regulatory standards for safety and labeling accuracy have never been more stringent. In this high-stakes environment, the beverage filling line is far more than a sequence of machines; it is the critical nexus where product quality, brand reputation, and profitability converge. Every decision made here, from the choice of a beverage filling machine to the design of the production workflow, has profound and lasting consequences.

The efficiency and quality of a beverage operation are paramount. A single, seemingly minor error on the packaging line—a few milliliters of overfill, a poorly sealed cap, or a moment of unnecessary downtime—can cascade into significant operational and financial liabilities. These issues manifest as wasted product, costly recalls, customer complaints that erode brand loyalty, and potential fines from regulatory bodies.

This pressure is intensified by a fundamental market shift. The modern consumer’s appetite for a vast array of flavors, sizes, and product categories has led to an explosion in Stock Keeping Units (SKUs). To meet this demand, manufacturers are compelled to move away from long runs of a single product toward shorter, more varied production batches. This, in turn, necessitates more frequent line changeovers, a primary source of non-productive downtime and a major risk factor for errors if not managed effectively. Consequently, a modern beverage filling system can no longer be evaluated on its steady-state speed alone. Its agility—the ability to switch between different products, containers, and caps quickly and flawlessly—has become a critical, market-driven performance metric.

The Foundational Challenge: Achieving Unwavering Fill Accuracy

At the core of every bottling operation lies the foundational challenge of dispensing the precise, intended amount of product into every single container. This is the bedrock of quality, compliance, and profitability. Failure to achieve consistent fill accuracy can undermine an entire operation.

The Physics of Inaccuracy: Causes of Inconsistent Fill Levels

Inaccurate filling is rarely the result of a single fault; it is often a symptom of complex, interacting variables within the production environment. Key causes include:

● Product Variability: The physical properties of the beverage itself are a primary factor. Fluctuations in temperature can alter a liquid’s viscosity (its resistance to flow), causing it to dispense differently from one batch to the next. Similarly, products with pulp, particulates, or high viscosity behave differently under pressure than thin, free-flowing liquids.

● Mechanical and Control Issues: The beverage bottling machine is a complex assembly of mechanical and electronic components. Over time, parts like fill valves, seals, and pumps can wear out, leading to leaks or inconsistent flow rates. Clogged nozzles can cause uneven distribution, while unstable air pressure in pneumatic systems can result in varied piston strokes and, therefore, inconsistent fill volumes. Furthermore, errors in the calibration of control systems, such as Programmable Logic Controllers (PLCs) and sensors, can lead to systematic inaccuracies.

● Foaming and Air Trapping: For many beverages, especially carbonated drinks or those that are agitated during processing, foaming is a significant challenge. Foam and trapped air pockets displace liquid in the container, leading to significant underfills once the product settles. This not only cheats the customer but also creates inconsistent appearances on the shelf.

The High Cost of Inaccuracy: Beyond Spilled Product

The consequences of inconsistent fill levels extend far beyond the production line.

● Financial Loss from Product Giveaway: Persistent overfilling is a direct financial drain. While a single overfilled bottle may seem insignificant, the cumulative loss of product over thousands or millions of units can amount to a substantial impact on the bottom line, especially for high-value products like premium spirits or cold-pressed juices.

● Erosion of Brand Trust and Regulatory Risk: Underfilling is even more perilous. It can trigger customer complaints, damage a brand’s reputation for quality and fairness, and lead to serious regulatory action, including hefty fines and mandated recalls. In the eyes of the consumer, consistency is synonymous with quality; a half-empty bottle is a broken promise.

The challenge of fill accuracy is not a static problem with a one-time fix. It is a dynamic variable that must be actively managed. A machine that seems to be “drifting” and requires constant recalibration may not be the root cause of the problem. Instead, its inconsistency could be a symptom of upstream issues, such as poor temperature control in a mixing tank affecting product viscosity. This reveals a deeper truth: solving fill accuracy requires a holistic view of the entire production line. The most effective solutions involve either a beverage filling machine smart enough to compensate for these variations or an integrated system where upstream process data informs and adjusts downstream filling parameters.

The Engineering Response: A Deep Dive into Precision Filling Technologies

To combat the challenge of inaccuracy, engineers have developed a range of sophisticated filling technologies. Each operates on a different scientific principle, offering a unique set of advantages tailored to specific beverage types and production goals. Choosing the right Filling Machine for Beverages is a strategic decision that directly impacts product quality and operational efficiency.

For Absolute Volumetric Precision: The Servo Piston Filler

For products where a precise volume is critical, the servo-driven piston filler represents the pinnacle of accuracy.

● Principle of Operation: This technology uses a positive displacement mechanism. A piston retracts within a precision-machined cylinder, drawing in an exact volume of product. The piston then extends, positively displacing that liquid through a nozzle and into the container.

● The Servo Revolution: While older piston fillers relied on pneumatic or mechanical drives susceptible to fluctuations in air pressure, modern machines utilize servo motors. A servo motor, controlled by a PLC, allows for exact, programmable command over the piston’s stroke length and speed. This enables operators to create a “filling profile,” for instance, starting the fill quickly and then slowing down as the container nears full to prevent splashing or foaming.

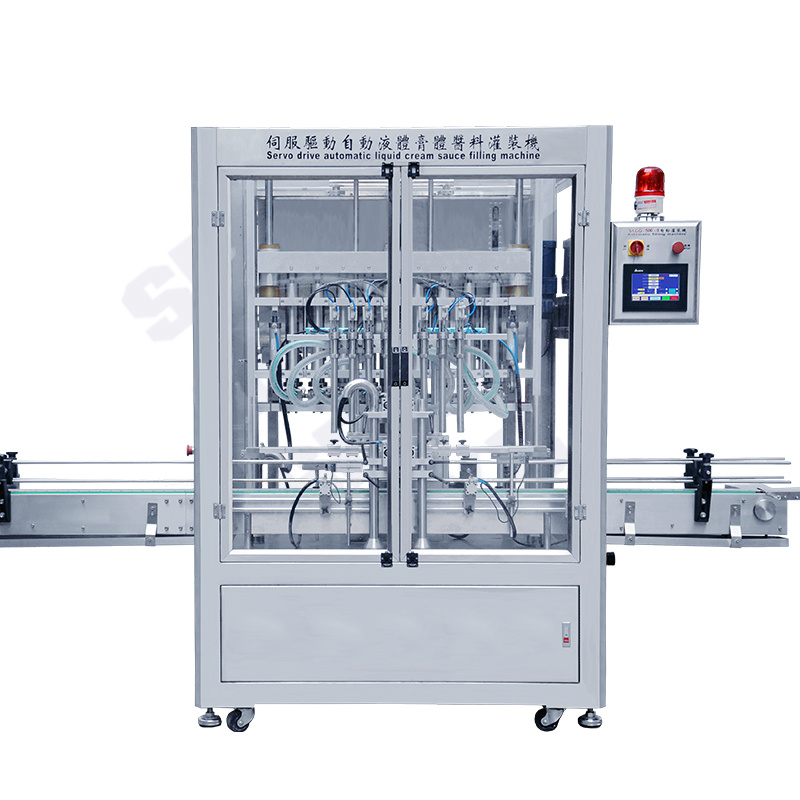

● Benefits: The result is exceptional accuracy, often achieving tolerances of ±0.25% or better, with outstanding repeatability from one cycle to the next. This precision minimizes product waste and makes servo piston fillers incredibly versatile, capable of handling everything from water-thin liquids to viscous pastes, sauces, and even products containing soft particles. A prime example is the XBGG series automatic multi-head servo drive piston filling machine from SFXB (Xueba Pack), which leverages this servo technology and hygienic 316L stainless steel construction to provide versatile, high-accuracy filling for sauces and liquids.

|

| XBGG series automatic multi-head servo drive piston filling machine |

For Ultimate Accuracy with High-Value Products: The Net-Weight Filler

When product cost is high or density varies, net-weight filling technology offers the ultimate safeguard against product giveaway.

● Principle of Operation: Instead of measuring volume, a net-weight filler measures weight. Each empty container is first placed on a high-precision scale, or load cell, and its empty weight (tare) is recorded. The machine then fills the container until a pre-programmed target weight is reached.

● Key Advantage: This method’s primary strength is its immunity to variations in product characteristics. Since it measures mass directly, it is unaffected by changes in product temperature, density, viscosity, or aeration. This makes it the most accurate and reliable method for high-value or inconsistent products, guaranteeing that every package contains the exact weight of product being sold.

● Smart Features: Advanced net-weight systems feature feedback loops that automatically adjust for the amount of “in-flight” product (liquid between the nozzle and the container surface) to further enhance accuracy. They can also reject containers that are out of tolerance before filling begins, preventing waste, and can provide detailed statistical data for every fill cycle, which is invaluable for quality control.

|

| XBCZ series automatic weighing liquid filling machine |

For Hygienic, Low-Maintenance Filling: The Magnetic Flowmeter Filler

For many water-based beverages, magnetic flowmeter fillers provide an elegant combination of accuracy and superior hygiene.

● Principle of Operation: This technology is based on Faraday’s Law of Electromagnetic Induction. As an electrically conductive liquid flows through a magnetic field generated by the filler, it induces a voltage. This voltage is directly proportional to the velocity of the fluid. A sensor measures this voltage, and a transmitter instantly converts it into a precise volumetric flow rate, cutting off the flow when the target volume is reached.

● Key Advantages: The most significant benefit is its non-invasive, obstructionless design. The product flows through a smooth pipe with no moving parts, pistons, or seals in the product path. This makes the system exceptionally hygienic, easy to clean using Clean-in-Place (CIP) methods, and extremely low-maintenance.

● Limitations: This technology is only suitable for liquids that are electrically conductive (typically with a conductivity greater than 5 microsiemens per centimeter, or 5μS/cm). This includes most juices, teas, and water-based drinks, but excludes products like oils or certain high-sugar syrups.

The choice of filling technology is not arbitrary; it is a calculated decision based on the specific challenges presented by the beverage. A producer of both still water and a high-value, viscous fruit concentrate would likely require two different filling lines to operate optimally. This underscores the importance of partnering with a packing machine china manufacturer that offers a diverse portfolio and the expertise to guide clients to the right solution for their unique business needs.

| Beverage Category | Primary Challenge | Recommended Filling Technology | Technical Rationale |

| Carbonated Soft Drinks, Beer | Carbonation Loss, Foaming | Counter-Pressure Filler | Equalizes pressure in the container and filling tank, preventing CO2 from escaping solution according to Henry’s Law. |

| Still Water, Thin Juices | Speed, Cost-Efficiency, Shelf Appeal | Gravity / Overflow Filler | A simple, high-speed mechanism ideal for low-viscosity liquids. Fills to a consistent level for excellent visual presentation. |

| Pulpy Juices, Sauces, Creams | Particulates, High Viscosity | Servo Piston Filler | Positive displacement provides the force needed to move viscous products and particulates accurately. Servo control allows for precise volume and speed adjustments. |

| High-Value Syrups, Spirits, Edible Oils | Extreme Accuracy, Product Giveaway | Net-Weight Filler | Fills to a precise weight, eliminating inaccuracies from density/temperature variations and minimizing waste of expensive product. |

| Milk, Plant-Based Drinks, Teas | Microbial Spoilage, Shelf Life | Aseptic Filling System | Sterilizes product and packaging separately to create a shelf-stable product without preservatives, meeting “clean label” demands. |

Managing Product Integrity: Solutions for Delicate and Carbonated Beverages

Beyond just dispensing the correct volume, a beverage filling machine must protect the inherent qualities of the product. For many popular beverages, this means managing the delicate balance of carbonation and preventing the formation of foam, which can degrade both quality and accuracy.

The Battle Against Foam: Preserving Product Quality and Fill Accuracy

Foam is the enemy of an efficient and high-quality filling operation. Caused by the agitation of the liquid and the release of dissolved or entrapped gas, it leads to inaccurate, low fills, product spillage, and increased dissolved oxygen, which can negatively impact the beverage’s flavor and shelf life. Two primary engineering solutions directly combat this issue:

● The Bottom-Up Filling Solution: This technique is a simple yet highly effective method for minimizing turbulence. Specialized nozzles on the filling machine for bottles descend to the bottom of the container before dispensing begins. As the liquid fills the container, the nozzles rise at a controlled, adjustable speed, always keeping the outlet submerged just below the surface of the liquid. This gentle, subsurface filling dramatically reduces splashing and agitation, thereby preventing foam from forming in the first place.

● The Overflow Filling Solution: Used in fill-to-level applications where a consistent cosmetic appearance on the shelf is paramount, overflow fillers offer another approach. These machines use special nozzles that create a seal on the container opening. They fill the container until the liquid reaches an overflow port in the nozzle. Excess product and any foam that has formed are then pushed out through this return port and back to a holding tank, ensuring every bottle has a perfectly uniform fill level and is free of foam.

Preserving the Fizz: The Science of Counter-Pressure Filling

For carbonated beverages like soft drinks, beer, and sparkling water, maintaining the dissolved carbon dioxide (CO2) is essential to the consumer experience. This requires a specialized technology known as counter-pressure filling.

● The Science: The process is governed by a principle of chemistry known as Henry’s Law, which states that the amount of a gas that can remain dissolved in a liquid is directly proportional to the pressure of that gas above the liquid’s surface. When a can of soda is opened, the sudden drop in pressure to atmospheric levels causes the dissolved CO2 to rapidly come out of solution, creating the characteristic fizz and foam. Counter-pressure filling works by preventing this pressure drop from ever occurring during the filling process.

● The Process: A counter-pressure filling machine for cans or bottles follows a precise sequence:

1.Pressurization: The empty container is first sealed and pressurized with CO2 gas to a pressure that is equal to or slightly higher than the pressure of the carbonated beverage in the main filling tank.

2.Gentle Filling: With the pressures equalized, the liquid filling valve opens. The beverage flows gently into the container via gravity or light pressure, without turbulence or a significant pressure differential. This keeps the CO2 safely dissolved in the liquid.

3.Snifting: After the fill is complete, the pressure in the container’s headspace is carefully and slowly released (a process called “snifting”) before the container moves to the capper or seamer.

● Key Factors for Success: To maximize carbonation retention, two factors are critical: maintaining a very low product temperature (as cold liquids hold more dissolved gas) and ensuring stable, precise pressure control throughout the entire line.

Effectively managing foam and carbonation requires a systems-level approach. It is an exercise in managing the energy—kinetic, thermal, and pressure—of the product throughout the line. A successful installation depends on optimizing all these factors, not just selecting a single piece of hardware.

The Aseptic Imperative: Guaranteeing Safety for Sensitive Products

For the growing market of health-conscious beverages—such as dairy and plant-based milks, natural juices, and functional teas—achieving a long shelf life without relying on preservatives is the ultimate goal. This is the realm of aseptic processing, the most advanced and hygienic method of beverage packaging.

The Challenge of Sensitive Beverages

Sensitive beverages are defined by their susceptibility to microbial spoilage. They typically have a low-acid or neutral pH, which creates a fertile environment for bacteria, yeasts, and molds to grow. Traditional preservation methods like hot-filling, which involves filling the product at high temperatures (e.g.,85−95∘C) to sterilize the package, can work but often come at the cost of degrading the product’s delicate flavors, colors, and nutritional value.

The Aseptic Filling System: A Paradigm of Sterility

An aseptic filling system overcomes these challenges by fundamentally changing the process. It is built on three uncompromising pillars of sterility:

1.Product Sterilization: The liquid beverage is sterilized separately before it enters the filling area. This is typically done using an Ultra-High Temperature (UHT) process, where the product is heated to very high temperatures (e.g., above 135∘C) for just a few seconds and then rapidly cooled. This brief, intense thermal treatment effectively kills microorganisms while preserving the product’s sensory and nutritional qualities far better than prolonged heating.

2.Packaging Sterilization: In parallel, the packaging materials—whether they are PET bottles, cartons, or pouches—are sterilized just before filling. This is commonly achieved using chemical sterilants like vaporized hydrogen peroxide (H2O2) or peracetic acid, followed by sterile air drying.

3.Sterile Filling Environment: The sterilized product is then filled into the sterilized containers inside a highly controlled, sterile environment (a microbiological isolator or cleanroom). This environment is maintained under positive pressure with HEPA-filtered air to prevent any possibility of recontamination from the surrounding atmosphere. The container is then hermetically sealed within this sterile zone.

The result is a commercially sterile, shelf-stable product that requires no refrigeration and no preservatives, perfectly meeting the consumer demand for “clean label” products. An aseptic line is not merely a machine but a complete, validated process. It requires that every single component in the product path after the UHT sterilizer—all pipes, valves, and the filler itself—be designed for sterilization and maintained in a sterile state. Any breach in this sterile chain compromises the entire production batch. This elevates the relationship between the manufacturer and the equipment supplier to a true partnership, one built on deep microbiological and engineering expertise.

Holistic Line Optimization: Efficiency Beyond a Single Machine

True manufacturing efficiency is not found in the peak speed of a single machine but in the smooth, integrated, and uninterrupted performance of the entire production line. This requires a focus on minimizing all forms of downtime and maximizing the flexibility of the entire beverage filling system.

The Challenge of Downtime: Conquering Changeovers and Container Variety

In today’s market, a filling line must be a chameleon, capable of adapting to a wide variety of container materials (filling machine for PET bottles, glass, filling machine for cans), shapes, and sizes. This necessity for frequent product changeovers is a major source of downtime. The solution lies in the principles of Quick Changeover, also known as Single-Minute Exchange of Die (SMED).

● The SMED Philosophy: SMED is a lean manufacturing methodology focused on systematically reducing equipment setup time. Its core principle is to differentiate between “internal” setup activities (those that can only be done when the machine is stopped) and “external” setup activities (those that can be prepared while the machine is still running the previous batch). The goal is to convert as many internal tasks to external ones as possible. For example, fetching and preparing the correct labels and caps for the next run is an external task that should be completed long before the line stops.

● Technologies for Fast Changeovers: Modern food packaging equipment is designed with SMED in mind. Features that enable rapid changeovers include tool-less components like quick-release clamps and hand-tightened knobs, color-coded change parts, digital measurement guides on HMIs, and automated power height adjustments for rails and filling heads. These innovations replace slow, manual adjustments with fast, repeatable, and error-proof procedures.

The Power of Integration: Rotary and Monoblock Systems

The physical layout and integration of machinery also play a crucial role in overall line efficiency.

● Linear vs. Rotary Fillers: Linear filling machines process containers in a straight line, stopping and starting them under each station. They are often flexible and cost-effective for smaller-scale operations. Rotary filling machines, in contrast, handle containers on a continuously rotating carousel. This continuous motion eliminates the start-stop inefficiency of linear indexing, making them ideal for high-speed, high-volume production.

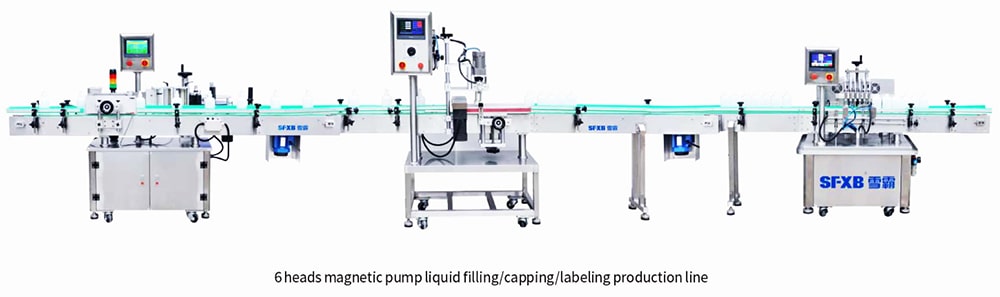

● The Monoblock Advantage: A monoblock system represents the highest level of integration. It combines multiple packaging functions—such as bottle rinsing, filling, and capping—onto a single, synchronized frame or chassis, often using a starwheel system for container transfer. This approach offers profound advantages over a line of separate, standalone machines. It dramatically reduces the factory footprint, eliminates the need for long, complex conveyor systems, simplifies line controls and synchronization, and reduces the number of operators required. By removing the potential for bottlenecks between machines, a monoblock system often achieves higher overall speed, reliability, and efficiency. Manufacturers like SFXB (Xueba Pack) specialize in these integrated automated production lines, demonstrating a capability to deliver these holistic, high-efficiency solutions.

The industry’s evolution from standalone machines to integrated monoblocks reflects a strategic shift in focus from the initial purchase price of equipment to its Total Cost of Ownership (TCO). While a monoblock may have a higher upfront cost, its savings in floor space, labor, energy, and improved Overall Equipment Effectiveness (OEE) result in a lower cost per unit produced over the life of the asset, which is the metric that truly matters.

Designing for Durability and Cleanliness

A beverage filling machine is a long-term asset that must operate reliably in a demanding environment. Its design must ensure not only performance but also absolute food safety and the ability to withstand rigorous cleaning protocols day after day.

The Foundation of Food Safety: Hygienic Design Principles

Hygienic design is a set of principles applied to equipment construction to ensure it can be cleaned effectively down to a microbiological level, preventing the harborage and growth of pathogens. Key principles include:

● Cleanable Surfaces: All product-contact surfaces must be exceptionally smooth (a surface roughness, or Ra, of less than 0.8 micrometers is a common standard), non-porous, and free of any cracks, pits, or crevices where microbes could hide.

● Compatible Materials: The choice of material is critical. Type 316L stainless steel is widely preferred for product contact parts due to its superior resistance to corrosion from both acidic products and harsh cleaning chemicals, compared to the more common 304 grade. All polymers, gaskets, and seals must be FDA-approved for food contact.

● Self-Draining Design: Equipment should be designed to be self-draining to prevent the pooling of liquid. This is achieved through sloped surfaces (a 30-degree sloped top is common on enclosures), rounded corners instead of sharp angles, and the elimination of any horizontal ledges.

● Hermetically Sealed Hollows: Hollow areas, such as frame tubes or support rollers, are a significant contamination risk. In a hygienic design, these areas are either eliminated in favor of solid construction or are permanently and hermetically sealed with continuous welds to ensure no product or moisture can penetrate them.

The Efficiency of Cleanliness: Automated Clean-in-Place (CIP) Systems

Clean-in-Place (CIP) systems are automated processes that clean the interior surfaces of the filling line without requiring disassembly, saving immense amounts of time and labor. The effectiveness of any CIP cycle depends on the precise control of four factors:

Time, Action (the mechanical force from fluid turbulence), Chemical concentration, and Temperature. A well-designed CIP system, often integrated with the beverage filling machine, optimizes these variables to ensure a validated, repeatable clean every time. It is also important to distinguish between CIP, which is designed to remove physical product residue (soils), and Sanitize-in-Place (SIP), which uses a sanitizer to kill any remaining microorganisms on the clean surfaces.

Hygienic design and CIP are inextricably linked. A machine with poor hygienic design—with dead legs, crevices, or poor drainage—cannot be cleaned effectively by an automated CIP system. This forces operators to compensate with longer wash times, higher chemical concentrations, or higher temperatures, all of which increase operating costs and extend downtime. Therefore, an initial investment in equipment with superior hygienic design provides a direct and continuous return through faster, more efficient, and more reliable cleaning cycles.

Conclusion: Your Filling Line Is a Strategic Asset

Navigating the complexities of the modern beverage industry requires more than just functional machinery; it demands strategic solutions. The challenges of fill accuracy, product integrity, foaming, carbonation, and microbial safety are not isolated hurdles but interconnected facets of a single, overarching goal: to deliver a high-quality, safe, and profitable product to the consumer.

Overcoming these challenges requires a holistic approach that views the filling line not as a collection of individual parts, but as a single, integrated system. The solution begins with selecting the right core filling technology—be it servo piston, net-weight, or counter-pressure—for the specific product portfolio. It extends to embracing technologies that enhance flexibility and minimize downtime, such as quick changeover designs and integrated monoblock systems. And it is founded upon the non-negotiable principles of hygienic design and automated cleaning that safeguard both the product and the brand.

Ultimately, the right beverage filling machine is a strategic asset. Choosing a manufacturing partner is as critical as choosing the machine itself. Success depends on collaborating with a supplier that possesses deep R&D capabilities, a demonstrable commitment to hygienic engineering, the flexibility to provide customized and integrated solutions, and the dedication to offer robust support for the entire lifecycle of the equipment. By making an informed, strategic investment in the right beverage filling system, manufacturers can conquer the challenges of today and build a resilient, efficient, and profitable operation for the future.

Frequently Asked Questions (FAQ) about Beverage Filling Machine

1.What is a beverage filling machine and why is it important?

A beverage filling machine is an automated system used to fill bottles or containers with liquid beverages. It is crucial for maintaining product quality, accuracy, and meeting regulatory standards. These machines help optimize production speed and reduce errors like overfilling or underfilling.

2.What are the common challenges faced in beverage filling processes?

Common challenges include fill accuracy, foam formation, product integrity (especially for carbonated or sensitive beverages), and downtime during changeovers. These can lead to financial loss, brand erosion, and compliance issues.

3.How does fill accuracy impact beverage production?

Fill accuracy is vital for product consistency, customer satisfaction, and compliance with regulations. Inaccurate filling can lead to product waste, customer complaints, and potential fines from regulatory bodies for underfilling or overfilling.

4.What technologies can improve fill accuracy?

Technologies like servo piston fillers, net-weight fillers, and magnetic flowmeter fillers can improve fill accuracy. These systems provide precise control over the filling process, ensuring that the correct volume or weight is dispensed in every container.

5.What causes foaming during the filling process and how can it be controlled?

Foaming occurs when air is trapped in the liquid, often caused by agitation or carbonated beverages. To control foaming, techniques like bottom-up filling and overflow filling are used, where liquid is dispensed gently, reducing turbulence and preventing foam formation.

6.What is the role of counter-pressure filling in carbonated beverages?

Counter-pressure filling prevents carbonation loss in beverages like soft drinks or beer. By maintaining equal pressure during the filling process, it ensures that dissolved CO2 remains in the liquid, preserving the product’s effervescence and quality.

7.How does an aseptic filling system help preserve sensitive beverages?

An aseptic filling system sterilizes both the product and its packaging before filling. This ensures that the product remains free from microbial contamination, extending shelf life without the need for preservatives, which is especially important for dairy, plant-based drinks, and juices.

8.Why is changeover flexibility important in beverage filling lines?

Beverage production today often requires switching between different container types and product variants. Quick changeover systems, such as Single-Minute Exchange of Die (SMED), minimize downtime and improve efficiency by reducing setup times.

9.What is the significance of hygienic design in beverage filling machines?

Hygienic design ensures that machines are easy to clean, preventing microbial growth and contamination. Key features include smooth, non-porous surfaces, FDA-approved materials, and self-draining designs, which facilitate quick and effective cleaning processes.

10.How do integrated monoblock systems improve production efficiency?

Monoblock systems integrate multiple functions (e.g., rinsing, filling, capping) into a single machine, reducing floor space, improving synchronization, and increasing speed. These systems streamline operations, reduce bottlenecks, and lower operational costs over time.

| References: | |

| 1. | 《Automatic Liquid Filling Machine》——Retrieved from:IJERT.ORG |

| 2. | 《Aseptic Filling Machines Market Size, Share, Outlook by 2032》——Retrieved from:Allied Market Research |

| 3. | 《Ensuring Quality and Food Safety of Aseptically Processed and Packaged Food and Beverages》 ——Retrieved from:Food Safety Magazine |

| 4. | 《Comparative Life Cycle Assessment of Hot Filling and Aseptic Packaging Systems for Beverages》——Retrieved from:Journal of Food Engineering |

| 5. | 《Aseptic Filling Machines Market Industry Trends and Opportunities to 2030》——Retrieved from:GlobeNewswire |

Comments