Introduction:Induction Aluminum Foil Sealing Machines are vital packaging devices that use electromagnetic induction to heat-seal foil liners in container caps. They create hermetic seals that prevent leaks, preserve freshness, and provide tamper-evident packaging.This non-contact sealing process rapidly melts the foil liner inside a cap onto the bottle neck when an alternating electromagnetic field is applied. Industries such as food and beverage, pharmaceuticals, and cosmetics rely on induction sealing to protect product integrity. As the market for induction sealing machines grows, choosing a reliable manufacturer becomes essential for ensuring high-quality, efficient sealing equipment.

Why Choosing the Right Manufacturer Matters

Selecting an experienced, reputable manufacturer ensures you get reliable equipment and support. Induction sealing machines integrate advanced electronics, coils, and control systems, so a proven supplier can minimize downtime and ensure consistent seal quality. Top manufacturers invest in R&D, quality control, and service. For example, leaders like Enercon emphasize helping “packagers prevent leaks, preserve freshness & provide tamper evidence” – a reminder that the right machine must deliver those benefits consistently. Buying from an established manufacturer with decades of expertise (such as SFXB, “one of the largest packaging machinery manufacturers” in China. means you gain better technical support, longer warranties, and compliance with safety standards. Ultimately, the right induction foil sealing machine supplier will safeguard product quality, meet production needs, and protect your brand reputation.

Top 10 Induction Aluminum Foil Sealing Machine Manufacturers Worldwide

1. Pillar Technologies (USA)

A founding innovator in induction sealing, Pillar Technologies introduced the first solid-state induction cap sealer in 1973. Based in Indiana, USA, Pillar focuses exclusively on induction bottle-sealing systems and related equipment. Its machines produce durable, high-quality seals that meet food, beverage, and pharmaceutical industry standards. With 50+ years of experience and a global customer base, Pillar is known for robust machines and expert technical support.

2. Sigma CapSeal (USA / India)

Sigma CapSeal is an industry-leading supplier of induction and cap-sealing machinery. The company notes that for “more than 45 years, Sigma CapSeal has offered world-class cap sealing solutions to more than 85 countries”. With global reach and a 250+ strong team, Sigma offers a range of induction sealers, cap liners, and closure machines for lines up to 100 feet/min. Its equipment is used across healthcare, dairy, chemicals, and consumer goods to ensure airtight foil seals. Sigma’s long history and international presence underscore its expertise in Induction Aluminum Foil Sealing Machines.

3. Enercon Industries (USA)

Enercon (USA) is widely regarded as a global leader in induction cap sealing and surface treatment solutions. With roughly 50 years in business, Enercon has “hermetically sealed billions & billions” of containers worldwide. Its Super Seal™ series includes high-speed cap sealer heads designed for food, beverage, pharma, and more. Enercon emphasizes reliability and customer support – its Packaging World profile highlights the company’s worldwide team dedicated to induction sealing. For companies seeking proven performance and extensive application expertise, Enercon’s induction sealers are a top choice.

4. Accutek Packaging Equipment (USA)

Accutek is one of the largest packaging machinery manufacturers in the United States. Founded in Texas, it offers complete turnkey solutions including filling, capping, labeling, and sealing machines. Accutek’s product line includes semi- and fully-automatic induction sealers compatible with foil liners and various cap types. According to its site, Accutek “manufactures a wide variety of… heat and induction sealing machines”as part of its systems. With over 35 years of industry experience and thousands of machines built, Accutek’s reputation for sturdy equipment and service makes it a trusted supplier of induction foil sealing technology.

5. Kaps-All Packaging Systems (USA)

Kaps-All (Riverhead, NY) has been an American-owned packaging machinery company since 1941. Although it produces a wide range of filler, capper, and labeling machines, Kaps-All is also known for its Auto-Mate® induction sealers. These portable to fully-automatic models provide precise foil sealing for bottle caps of all sizes. The company’s 72+ years in business reflect deep expertise in sealing technology. Packagers cite Kaps-All’s reliable performance and customer focus, a legacy that “has made them the proven standard of the packaging industry”. Kaps-All’s induction sealers (including its patented Waterless Cap Sealers) are built for demanding production lines requiring tamper-proof foil sealing.

6. Grand Intelligent Equipment (China)

Founded in 2006 and ISO-certified, Grand Machinery specialises in R&D and manufacturing of pharmaceutical and packaging equipment, including high-efficiency electromagnetic induction foil cap sealers. Their air-cooled induction sealing machines deliver reliable, continuous aluminum foil sealing for bottles and containers, serving over 160 countries with robust after-sales support and a 6,000 m²+ production facility staffed by 100+ professionals.

7. ForBropack (For-Bro Engineers, India)

For-Bro Engineers (ForBropack) is a Mumbai-based manufacturer founded in 1978. Over 40+ years, it has become one of India’s leading packaging machine companies, producing a range of equipment including bottle fillers, cappers, and induction sealers. Its induction sealing machines can handle diverse pouch and bottle sizes, with adjustable platforms and digital temperature controls. According to industry profiles, “ForBropack was established in India in 1978… and until now it has become one of the most top packaging machine manufacturers in India”. The company’s local market expertise and long track record make it a go-to source for reliable induction foil sealing equipment in South Asia.

8. Me.Ro (Merlo Scipioni, Italy)

Me.Ro, headquartered in Lucca, Italy, has over 60 years of experience in electronic instruments and plastic treatment equipment. While known for corona and plasma treaters, Me.Ro also produces induction sealing systems. Its catalog includes advanced cap sealing machines (manual to automatic) using IGBT inverter technology for high efficiency. According to industry reports, “Me.Ro is Italy’s one of the leading electronics instrument manufacturers… started their business in mid-1960s and today after 60 years they are globally distributing their machines”. This longevity and international presence underline Me.Ro’s expertise. Packaging companies in Europe often choose Me.Ro for precision sealing units backed by Italian engineering.

9. ATCO (Atco World, UAE)

ATCO is a Dubai-based equipment integrator and supplier with over 20 years in the MENA region. As part of ATCO Group, the company offers a broad portfolio of packaging solutions, including induction foil sealing machines. ATCO partners with OEMs like Alfa Laval and Inductoheat to provide complete lines.The firm emphasizes its 20+ years of service in the region and sells machines both as standalone units and line modules. For Middle East customers seeking local support and training, ATCO provides tailored induction sealing systems and spare parts.

10. Guangzhou SFXB Special Equipment (XuebaPack.com, China)

Guangzhou SFXB is a Chinese company specializing in packaging production lines. As its website states, “SFXB is one of the premier packaging machinery manufacturers specializing in… aluminum foil sealing machines”. The company offers R&D and manufacturing of electromagnetic induction aluminum foil sealing machines, along with filling, capping, and labeling equipment. SFXB highlights itself as “the most professional manufacturer of electromagnetic induction aluminum foil sealing machines with the most complete product varieties in China”. In practice, SFXB provides everything from tabletop induction sealers to in-line automatic systems. Its broad product range and domestic focus make SFXB a key player in China’s market for foil-cap sealing technology.

Factors to Consider When Choosing a Manufacturer

Selecting the right Induction Aluminum Foil Sealing Machine manufacturer involves more than just looking at a list of names. Here are key factors to consider:

Production Volume: Determine your required throughput. Manual sealers are suitable for low volume, while automatic systems are essential for high production lines.

Container Type and Size: Ensure the machine is compatible with your specific container materials (plastic, glass), shapes, and sizes.

Foil Liner Specifications: The machine must be compatible with the type of aluminum foil liners you will be using.

Integration Capabilities: If you have an existing packaging line, consider how easily the new sealer can be integrated.

Ease of Operation and Maintenance: Look for machines with intuitive controls and simple maintenance procedures to minimize downtime.

Safety Features: Prioritize machines with robust safety features to protect operators.

Customer Support and After-Sales Service: Reliable technical support, spare parts availability, and training are crucial for long-term operational success.

Budget: Induction sealing machines vary significantly in price depending on their features and automation level.

Technological Advancements in Induction Sealing

The field of induction sealing is constantly evolving. Leading manufacturers are incorporating advanced technologies to improve efficiency, reliability, and versatility. Some key advancements include:

Advanced Power Supplies: More efficient and precise power supplies ensure consistent heating and optimal seal quality.

Integrated Inspection Systems: Vision systems and other sensors can detect missing or improperly seated caps and seals, preventing faulty products from reaching consumers.

Automated Reject Systems: Machines can automatically reject containers with faulty seals, minimizing waste and ensuring product integrity.

Remote Monitoring and Diagnostics: Some advanced systems offer remote monitoring capabilities, allowing for real-time performance tracking and remote troubleshooting.

Energy Efficiency: Manufacturers are focusing on developing more energy-efficient machines to reduce operating costs and environmental impact.

Flexibility and Versatility: Modern sealers are designed to handle a wider range of container sizes and types, offering greater flexibility for businesses with diverse product lines.

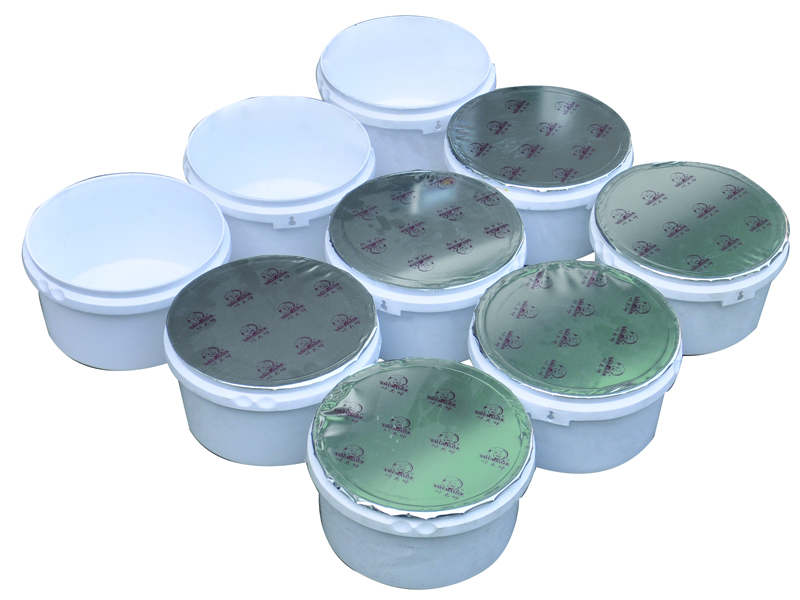

The Role of Consumables: Aluminum Foil Liners

It’s important to remember that the quality of the aluminum foil liner is just as crucial as the quality of the sealing machine. The liner is the component that actually creates the seal. Manufacturers like SFXB also offer a range of high-quality aluminum foil sealing machine consumables designed to work seamlessly with their machines and ensure optimal sealing performance. Choosing the right liner based on container material and product type is essential for achieving a strong and reliable seal.

Conclusion

Selecting the right manufacturer for your induction aluminum foil sealing machine is critical for ensuring product safety, quality, and efficiency. The companies listed above represent highly experienced, technically proficient suppliers of induction sealing equipment. Whether you need a compact benchtop sealer or a high-speed inline system, each of these manufacturers has a proven track record in providing robust, reliable machines. By choosing a reputable supplier – one with decades of expertise and strong customer support – you’ll obtain a sealing machine that consistently delivers airtight, tamper-evident foil seals. In turn, this protects your products’ freshness and your brand’s reputation in demanding markets.

| References: | |

| 1. | Enercon Industries “A Beginner’s Guide to Induction Sealing” –Retrieved from: https://www.enerconind.co.uk/wp-content/uploads/2020/02/A-Beginners_Guide_to_Induction_Cap_Sealing-1.pdf |

| 2. | “Induction sealing” –Retrieved from: Wikipedia |

| 3. | Academic study on the effect of induction sealing and time on removal torque in pharmaceutical bottle packaging, with statistical analysis of tamper-evident performance.–Retrieved from:Giles & Bain RIT Thesis, Rochester Institute of Technology |

| 4. | The Wiley Encyclopedia of Packaging Technology |

Comments