Dalam dunia dinamik penjagaan kesihatan dan farmaseutikal, permintaan untuk ubat-ubatan yang selamat, cekap dan ditadbir dengan tepat adalah yang utama. Di antara pelbagai sistem penyampaian ubat, picagari pra-isi telah muncul sebagai inovasi transformatif, memperkemas proses pentadbiran dan meningkatkan keselamatan pesakit dengan ketara. Penerokaan komprehensif ini menyelidiki aspek asas picagari yang telah diisi sebelumnya, menjawab soalan utama tentang identiti, tujuan, kelebihannya dan cara ia berbeza daripada botol tradisional. Tambahan pula, kami akan menyiasat jentera canggih yang menyokong pengeluaran mereka - Mesin Pengisi Picagari yang sangat diperlukan.

Apakah yang dipanggil Picagari Pra-Isi? Menghurai Terminologi

Walaupun nampaknya mudah, istilah yang mengelilingi picagari pra-isi kadangkala boleh menjadi titik penjelasan. Pada terasnya, picagari pra-isi ialah picagari yang disertakan dengan dos ubat atau larutan tertentu yang telah terkandung dalam tongnya. Ia sedia untuk digunakan serta-merta selepas dikeluarkan daripada bungkusannya, menghapuskan keperluan untuk menarik ubat dari bekas yang berasingan seperti botol.

Walau bagaimanapun, dalam landskap industri dan kawal selia, anda mungkin menghadapi pelbagai istilah yang menerangkan atau berkaitan dengan picagari yang telah diisi sebelumnya. Ini boleh termasuk:

● PFS (Pra-Filled Syringe): Ini adalah akronim yang paling biasa dan diterima secara meluas untuk picagari pra-isi.

● Picagari Sedia Digunakan: Istilah ini menyerlahkan kebolehgunaan segera peranti.

● Suntikan Pra-Isi: Ini menekankan kaedah penghantaran, terutamanya apabila ubat diberikan melalui suntikan.

● Picagari Unit Dos: Istilah ini menekankan bahawa setiap picagari mengandungi satu dos ubat pra-ukur, mengurangkan risiko kesilapan dos.

● Picagari Jarum Praisi: Istilah khusus ini digunakan apabila jarum sudah dipasang pada tong picagari, seterusnya meminimumkan langkah penyediaan.

Walaupun istilah ini mungkin mempunyai nuansa halus dalam penggunaannya, semuanya pada asasnya merujuk kepada konsep yang sama: picagari pra-muat dengan ubat, direka untuk pentadbiran langsung. Memahami istilah ini adalah penting untuk komunikasi yang jelas dalam industri penjagaan kesihatan dan farmaseutikal.

Apakah Tujuan Picagari Pra-Isi? Anjakan Paradigma dalam Pentadbiran Dadah

Kemunculan picagari pra-isi mewakili anjakan paradigma yang ketara dalam cara ubat ditadbir, didorong oleh pelbagai tujuan kritikal yang memberi kesan secara langsung kepada penjagaan pesakit, kecekapan penjagaan kesihatan dan integriti dadah. Tujuan utama picagari pra-isi adalah untuk memudahkan dan menyeragamkan proses pemberian ubat. Dengan menghapuskan langkah-langkah mengambil ubat dari botol, profesional penjagaan kesihatan menjimatkan masa yang berharga dan mengurangkan potensi kesilapan yang berkaitan dengan penyediaan manual.

Di luar tujuan asas ini, picagari yang telah diisi mempunyai beberapa fungsi penting yang lain:

● Memastikan Ketepatan Dos: Setiap picagari pra-isi mengandungi dos ubat yang tepat dan pra-ukur. Ketepatan yang wujud ini adalah penting untuk ubat-ubatan yang walaupun penyelewengan kecil dalam dos boleh mempunyai implikasi klinikal yang ketara. Ia meminimumkan risiko kurang dos atau dos berlebihan, yang boleh mengancam nyawa.

● Mengurangkan Sisa Ubat: Tidak seperti botol di mana sisa ubat boleh ditinggalkan selepas mengambil dos, picagari pra-isi mengandungi jumlah tepat yang diperlukan untuk satu pentadbiran. Ini mengurangkan pembaziran ubat dengan ketara, yang membawa kepada penjimatan kos dan penggunaan ubat berharga yang lebih cekap.

● Meminimumkan Risiko Pencemaran: Sistem tertutup picagari yang telah diisi, selalunya dengan jarum dan penutup yang telah dipasang sebelumnya, meminimumkan pendedahan ubat kepada alam sekitar. Ini mengurangkan risiko pencemaran mikrob, mengekalkan kemandulan dan integriti ubat.

● Meningkatkan Keselamatan Pesakit: Dengan memudahkan proses pentadbiran dan mengurangkan potensi ralat, picagari pra-isi secara langsung menyumbang kepada keselamatan pesakit yang lebih baik. Mereka amat berfaedah dalam situasi kecemasan atau untuk pentadbiran sendiri oleh pesakit di rumah, di mana kemudahan penggunaan dan mengurangkan kerumitan adalah yang terpenting.

● Meningkatkan Jangka Hayat dan Kestabilan: Persekitaran terkawal dalam picagari pra-isi, selalunya dengan penyumbat dan pengedap tertentu, boleh meningkatkan kestabilan dan jangka hayat ubat-ubatan tertentu. Ini amat penting untuk ubat sensitif atau tidak stabil yang mungkin merosot apabila terdedah kepada udara atau faktor persekitaran lain.

● Memudahkan Latihan yang Lebih Mudah: Melatih profesional penjagaan kesihatan tentang penggunaan picagari yang telah diisi secara amnya adalah lebih mudah dan memerlukan lebih sedikit masa berbanding dengan mengajar proses pelbagai langkah mengambil ubat dari botol. Ini menyelaraskan latihan dan meningkatkan kecekapan keseluruhan.

● Membolehkan Pentadbiran Sendiri Pesakit: Untuk keadaan kronik yang memerlukan suntikan biasa (seperti diabetes atau penyakit autoimun tertentu), picagari pra-isi dengan reka bentuk mesra pengguna membolehkan pesakit menguruskan sendiri ubat mereka di rumah. Ini meningkatkan autonomi dan kemudahan pesakit.

Pada dasarnya, tujuan picagari pra-isi adalah untuk menghantar ubat dengan selamat, tepat, cekap, dan dengan risiko ralat atau pencemaran yang minimum, akhirnya meningkatkan kualiti penjagaan pesakit.

Apakah Kelebihan Picagari Pra-Isi? Kes Menarik untuk Pengangkatan

Penggunaan meluas picagari pra-isi di pelbagai kawasan terapeutik adalah bukti kelebihannya yang banyak dan menarik. Faedah ini diberikan kepada profesional penjagaan kesihatan, pesakit dan industri farmaseutikal itu sendiri.

Berikut adalah beberapa kelebihan utama picagari pra-isi:

● Peningkatan Keselamatan Pesakit: Seperti yang dinyatakan sebelum ini, ini mungkin kelebihan yang paling ketara. Mengurangkan kesilapan ubat, mengurangkan risiko pencemaran, dan pentadbiran yang dipermudahkan secara langsung menyumbang kepada hasil pesakit yang lebih baik.

● Ketepatan dan Kebolehpercayaan Dos yang Dipertingkatkan: Menghapuskan keperluan untuk lukisan manual memastikan bahawa pesakit menerima tepat, dos yang dimaksudkan setiap kali, yang penting untuk ubat-ubatan dengan tingkap terapeutik yang sempit.

● Mengurangkan Risiko Kecederaan Tertusuk Jarum: Banyak picagari pra-isi dilengkapi dengan ciri keselamatan bersepadu, seperti jarum yang boleh ditarik balik atau pelindung jarum, yang mengurangkan risiko kecederaan akibat tertusuk jarum secara tidak sengaja untuk profesional penjagaan kesihatan.

● Kecekapan Aliran Kerja Dipertingkat: Picagari pra-isi menjimatkan masa yang berharga untuk jururawat dan penyedia penjagaan kesihatan lain dengan menghapuskan keperluan untuk langkah penyediaan seperti penyusunan semula, menarik daripada botol, dan mengira dos. Ini membolehkan mereka memberi lebih tumpuan kepada penjagaan pesakit.

● Mengurangkan Sisa Ubat dan Penjimatan Kos: Dengan menyediakan dos tunggal yang tepat, picagari pra-isi meminimumkan sisa ubat dalam botol, membawa kepada penjimatan kos yang besar untuk kemudahan penjagaan kesihatan.

● Meningkatkan Kemandulan dan Mengurangkan Risiko Pencemaran: Sistem tertutup dan proses pembuatan steril picagari pra-isi dengan ketara mengurangkan risiko pencemaran mikrob, faktor kritikal dalam mencegah jangkitan.

● Jangka hayat yang dilanjutkan untuk ubat-ubatan tertentu: Persekitaran yang dikawal dengan teliti dalam picagari pra-isi boleh memberikan kestabilan yang lebih baik dan jangka hayat yang lebih lama untuk ubat sensitif tertentu berbanding dengan menyimpannya dalam botol.

● Keselesaan dan Kemudahan Penggunaan: Untuk kedua-dua profesional penjagaan kesihatan dan pesakit, picagari pra-isi menawarkan tahap kemudahan yang tinggi dan mudah digunakan, walaupun untuk individu yang mempunyai ketangkasan yang terhad.

● Kemudahan Pentadbiran Sendiri Pesakit: Untuk keadaan kronik, picagari pra-isi memperkasakan pesakit untuk menguruskan rawatan mereka sendiri, meningkatkan pematuhan dan kualiti hidup.

● Pembezaan dan Kelebihan Pemasaran: Bagi syarikat farmaseutikal, menawarkan ubat dalam picagari pra-isi boleh menjadi pembeza yang ketara dalam pasaran, menarik kepada penyedia penjagaan kesihatan dan pesakit yang mengutamakan kemudahan dan keselamatan.

Kelebihan ini secara kolektif menjadikan kes yang kukuh untuk peningkatan penggunaan picagari pra-isi, terutamanya untuk ubat-ubatan bernilai tinggi, vaksin dan ubat-ubatan yang memerlukan dos yang tepat dan pentadbiran steril.

Apakah Perbezaan Antara Vial dan Picagari Prefilled? Kisah Dua Bekas

Untuk menghargai sepenuhnya faedah picagari yang telah diisi sebelumnya, adalah berguna untuk memahami bagaimana ia berbeza daripada botol tradisional, yang secara sejarahnya merupakan pembungkusan standard untuk banyak ubat suntikan. Perbezaan teras terletak pada langkah penyediaan yang diperlukan sebelum pentadbiran.

Pada dasarnya, vial adalah bekas yang menyimpan ubat, manakala picagari pra-isi adalah kedua-dua bekas dan sistem penghantaran, direka untuk pentadbiran segera. manakala vial kekal penting untuk pelbagai aplikasi, picagari pra-isi menawarkan kelebihan ketara dari segi keselamatan, ketepatan dan kemudahan, terutamanya untuk pentadbiran dos tunggal.

Bagaimanakah Picagari Pra-Isi Diisi? Peranan Mesin Pengisi Picagari

Proses yang teliti untuk mengisi picagari yang telah diisi dengan dos ubat yang tepat adalah langkah kritikal dalam pengeluarannya. Proses ini tidak dilakukan secara manual untuk pengeluaran volum tinggi kerana keperluan untuk ketepatan, kemandulan dan kecekapan yang melampau. Sebaliknya, ia dijalankan oleh peralatan yang sangat khusus dan automatik yang dikenali sebagai Mesin Pengisi Syringe.

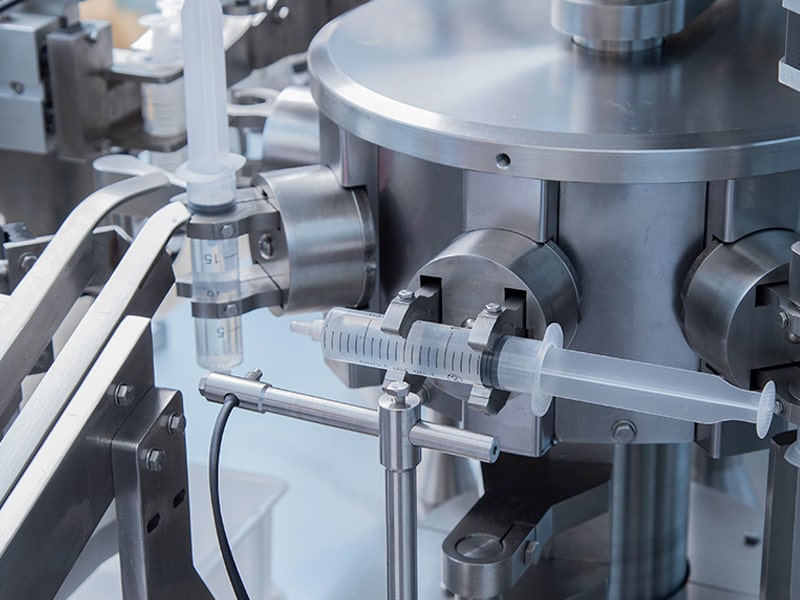

Mesin Pengisi Picagari ialah nadi teknologi pengeluaran picagari pra-isi. Mesin ini direka bentuk untuk mengendalikan pelbagai jenis dan saiz picagari, mengisinya dengan ubat cecair steril atau penyelesaian dengan ketepatan dan kelajuan yang luar biasa. Proses ini biasanya melibatkan beberapa peringkat utama:

1. Suapan Picagari: Picagari steril yang kosong dimasukkan ke dalam mesin dari corong atau dulang. Mesin ini direka untuk mengendalikan picagari kaca atau plastik yang halus tanpa kerosakan.

2. Pengisian: Ini adalah fungsi teras. Mesin menggunakan pam dos yang sangat tepat (selalunya pam peristaltik, omboh, atau omboh berputar) untuk mengeluarkan jumlah ubat yang tepat dari takungan dan menyalurkannya ke dalam tong picagari. Proses pengisian berlaku di bawah keadaan steril yang dikawal ketat, selalunya dalam tudung aliran laminar atau pengasing untuk mengelakkan pencemaran.

3. Sisipan Sumbat: Selepas mengisi, penyumbat steril dimasukkan ke dalam tong picagari. Penyumbat ini mencipta kedap hermetik, menghalang kebocoran dan mengekalkan kemandulan ubat.

4. Sisipan Rod Plunger (Pilihan): Untuk beberapa picagari yang telah diisi sebelumnya, batang pelocok dimasukkan pada peringkat ini, membolehkan penggunaan mudah oleh pengguna.

5. Penutup/Perisai Jarum: Jika picagari mempunyai jarum pra-dipasang, pelindung jarum atau penutup digunakan untuk melindungi jarum dan mengekalkan kemandulan. Untuk picagari tanpa jarum pra-dipasang, penutup hujung digunakan.

6. Pemeriksaan dan Kawalan Kualiti: Sepanjang proses, penderia dan sistem penglihatan yang canggih digunakan untuk memeriksa picagari untuk memastikan isipadu pengisian yang betul, penempatan penyumbat dan sebarang kecacatan. Picagari yang ditolak dikeluarkan secara automatik dari talian.

7. Pelabelan dan Pembungkusan: Picagari yang diisi dan dimeterai kemudian dilabelkan dengan maklumat produk, dos, dan tarikh luput. Ia kemudiannya dibungkus ke dalam pek lepuh, karton, atau pembungkusan sekunder lain untuk diedarkan.

Mesin Pengisian Picagari datang dalam pelbagai konfigurasi, daripada model atas bangku separa automatik untuk pengeluaran kelompok yang lebih kecil kepada talian berkelajuan tinggi, automatik sepenuhnya yang mampu mengisi beribu-ribu picagari sejam. Mereka direka bentuk untuk mengendalikan ciri khusus ubat yang berbeza, termasuk kelikatan, kepekaan terhadap udara dan keperluan suhu.

|

|

| Mesin pengisian picagari pelbagai fungsi menegak separa automatik | Mesin pengisian dan penutup untuk picagari plastik praisi |

Ciri-ciri utama Mesin Pengisi Picagari moden yang menyumbang kepada kecekapan dan ketepatannya termasuk:

● Sistem Dos Ketepatan Tinggi: Memastikan volum pengisian yang tepat dan konsisten.

● Persekitaran Pengisian Steril: Beroperasi dalam tudung aliran laminar atau pengasing untuk mengekalkan keadaan aseptik.

● Sistem Pengendalian Automatik: Pengendalian lembut picagari halus untuk mengelakkan pecah.

● Sistem Kawalan Kualiti Bersepadu: Pemeriksaan masa nyata dan penolakan produk yang rosak.

● Fleksibiliti dan Keupayaan Perubahan: Keupayaan untuk mengendalikan saiz picagari yang berbeza dan isipadu isipadu.

● Sistem Clean-in-Place (CIP) dan Sterilize-in-Place (SIP): Memudahkan pembersihan dan pensterilan mesin yang mudah dan berkesan.

Teknologi dalam Mesin Pengisi Picagari sentiasa berkembang, dengan kemajuan dalam teknologi robotik, automasi dan penderiaan yang membawa kepada ketepatan, kelajuan dan kecekapan yang lebih tinggi dalam pengeluaran picagari pra-isi.

|

|

| Mesin pengisian kuantitatif pelocok seramik tanpa injap siri XBWG |

Dari Konsep ke Bekas: Perjalanan Picagari Pra-Isi

Perjalanan picagari pra-isi, dari konsep awal ubat yang memerlukan kaedah penghantaran ini kepada pembungkusan terakhirnya, adalah proses yang kompleks dan sangat dikawal. Mesin Pengisi Picagari memainkan peranan penting dalam mengubah ubat pukal menjadi picagari pra-isi yang sedia untuk digunakan.

Bayangkan vaksin baru sedang dibangunkan. Setelah bahan ubat dirumus dan menjalani ujian yang ketat, keputusan mungkin dibuat untuk membungkusnya dalam picagari yang telah diisi terlebih dahulu untuk memudahkan pemberian semasa kempen vaksinasi besar-besaran. Di sinilah Mesin Pengisi Picagari menjadi sangat diperlukan.

Syarikat farmaseutikal akan memilih atau mereka bentuk format picagari pra-isi yang sesuai (kaca atau plastik, saiz tertentu, jenis penyumbat). Pengilang Mesin Pengisi Picagari kemudiannya akan mengkonfigurasi peralatan mereka untuk mengendalikan ciri picagari khusus ini. Vaksin pukal dibekalkan kepada kemudahan pengisian dalam bekas steril. Mesin Pengisi Picagari kemudiannya disediakan dengan teliti dan disahkan untuk memastikan ia boleh mengisi picagari dengan vaksin dengan tepat dan steril.

Semasa proses pengisian, mesin beroperasi pada kelajuan tinggi, mengisi setiap picagari dengan tepat, memasukkan penyumbat, dan menggunakan penutup atau perisai yang diperlukan. Sistem kawalan kualiti bersepadu sentiasa memantau proses, memastikan setiap picagari yang diisi memenuhi piawaian kualiti yang ketat yang diperlukan untuk produk farmaseutikal.

Selepas mengisi dan mengedap, picagari diproses selanjutnya, termasuk pelabelan, pembungkusan, dan kemungkinan pensterilan jika diperlukan (walaupun banyak picagari pra-isi diisi dengan ubat yang disterilkan secara tamat). Picagari pra-isi yang dibungkus terakhir kemudiannya diedarkan ke hospital, klinik, dan farmasi, sedia untuk diberikan kepada pesakit.

Tanpa teknologi canggih dan ketepatan Mesin Pengisi Picagari, pengeluaran besar-besaran picagari pra-isi yang selamat dan tepat adalah mustahil. Ia merupakan peralatan kritikal dalam proses pembuatan farmaseutikal, membolehkan penghantaran ubat dan vaksin yang menyelamatkan nyawa dengan cekap dan boleh dipercayai.

Kesimpulan: Masa Depan Penyampaian Ubat adalah Pra-Diisi

Picagari pra-isi telah merevolusikan pentadbiran ubat, menawarkan kelebihan ketara dari segi keselamatan, ketepatan, kecekapan dan kemudahan. Penggunaannya yang meluas adalah bukti nilainya dalam penjagaan kesihatan moden. Memahami apa itu picagari yang telah diisi sebelumnya, tujuannya yang pelbagai rupa, dan kelebihan menarik yang ditawarkannya adalah penting bagi sesiapa yang terlibat dalam industri farmaseutikal atau penjagaan kesihatan.

Perbezaan antara vial dan picagari pra-isi terletak pada asasnya pada penyediaan yang diperlukan, dengan picagari pra-isi menawarkan penyelesaian sedia untuk digunakan yang meminimumkan langkah dan mengurangkan risiko ralat.

Di tengah-tengah pengeluaran picagari pra-isi adalah teknologi canggih bagi Mesin Pengisi Picagari. Mesin canggih ini bertanggungjawab untuk mengisi picagari yang tepat dan steril, memastikan integriti dan kebolehpercayaan produk akhir. Memandangkan permintaan untuk picagari pra-isi terus berkembang, didorong oleh faktor-faktor seperti peningkatan kelaziman penyakit kronik, pembangunan biologi baharu, dan keperluan untuk program vaksinasi yang cekap, peranan Mesin Pengisi Picagari akan menjadi lebih kritikal.

Melabur dalam Mesin Pengisian Picagari yang boleh dipercayai dan canggih adalah penting bagi pengeluar farmaseutikal yang ingin memenuhi permintaan yang semakin meningkat untuk picagari pra-isi dan menyumbang kepada sistem penghantaran ubat yang lebih selamat dan cekap di seluruh dunia. Masa depan penghantaran ubat semakin terisi, dan teknologi yang memungkinkannya tertumpu pada ketepatan dan automasi Mesin Pengisian Picagari.

Dengan menerima kelebihan picagari pra-isi dan menggunakan teknologi Mesin Pengisi Picagari termaju, industri farmaseutikal boleh terus memajukan penjagaan kesihatan dan meningkatkan hasil pesakit pada skala global.

| Rujukan: | |

| 1. | Picagari Kaca untuk Menghantar Ubat dan Produk Biologi – Tambahan Maklumat Teknikal –Diperoleh daripada: Dokumen Panduan FDA |

| 2. | Menilai Kesan Penggunaan Sumber Klinikal, Ekonomi dan Kesihatan bagi Picagari yang Diisi: Kajian Sistematik –Diperoleh daripada: Abstrak PubMed |

| 3. | Picagari praisi: Satu inovasi dalam pembungkusan parenteral -Diperoleh daripada: Teks Penuh PMC |

| 4. | Bijak Membuat Picagari Terisi: Penyelesaian Teknologi untuk Memajukan Penjagaan Pesakit & Hasil Percubaan Klinikal –Diperoleh daripada: PEMBANGUNAN & PENGHANTARAN DADAH |

Komen