Introducción a las tecnologías de sellado: Los envases modernos suelen requerir sellos herméticos y de seguridad. Dos métodos comunes son el sellado por inducción y el termosellado. El sellado por inducción utiliza un campo electromagnético para unir un revestimiento de aluminio bajo una tapa sin tocar el envase. Por el contrario, el termosellado utiliza calor y presión por contacto directo para soldar los materiales de envasado (generalmente películas de plástico). Ambos métodos crean sellos resistentes, pero sus procesos, materiales y aplicaciones difieren. Comprender estas tecnologías ayuda a los fabricantes, desde productores de alimentos y productos farmacéuticos hasta envasadores industriales, a elegir la solución de sellado adecuada para sus productos.

Cómo funciona el sellado por inducción

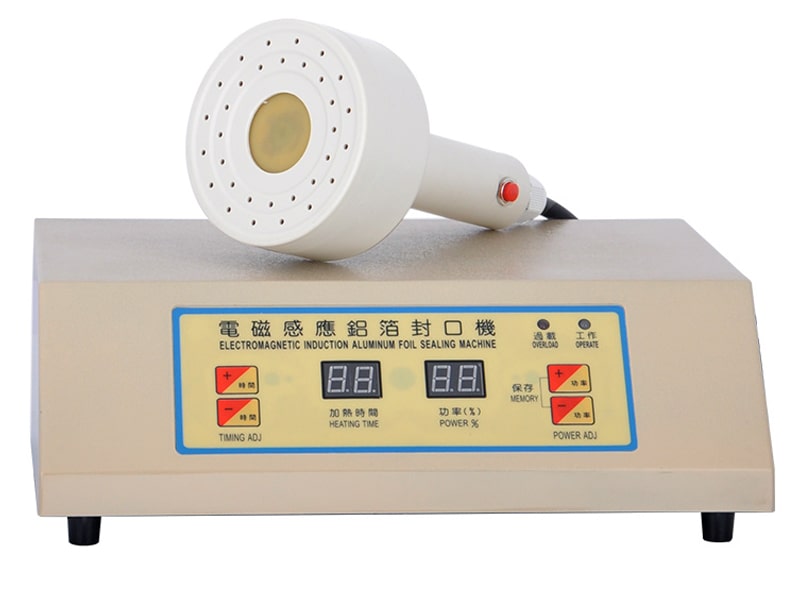

Las máquinas de sellado por inducción crean un sello hermético a prueba de manipulaciones en botellas o frascos tapados mediante un proceso sin contacto. El cierre (tapa) viene preinstalado con un revestimiento de inducción térmica: un disco multicapa hecho de pulpa de papel, cera, papel de aluminio y una película de polímero. Cuando el envase lleno y tapado pasa por debajo del cabezal de sellado por inducción, un campo electromagnético oscilante induce corrientes parásitas en el papel de aluminio conductor. Estas corrientes calientan el papel, derritiendo la cera y ablandando el polímero. A medida que el polímero fluye y se enfría en el borde del envase, se adhiere a este, creando un sello hermético. Dado que el proceso no implica llamas ni superficies calientes en contacto con el producto, el sellado por inducción es más seguro y no daña el contenido sensible al calor. Para mayor flexibilidad, selladores de inducción portátiles Existen para líneas de bajo volumen o controles de calidad, y las máquinas de sellado por inducción automatizadas manejan el sellado de tapas de botellas a alta velocidad con precisión.

Cómo funciona el sellado térmico

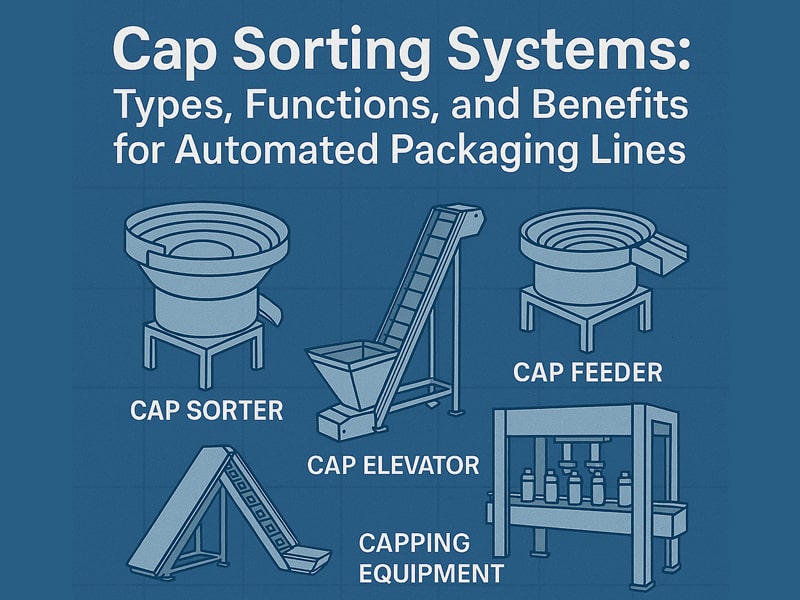

Las máquinas de sellado térmico unen físicamente las películas de embalaje mediante la aplicación de calor y presión. En la práctica, se colocan dos capas de material termoplástico (p. ej., polietileno o polipropileno) entre barras calentadas o un elemento calefactor por impulsos. El calor funde las capas de polímero en su interfaz; la presión las fusiona formando una costura sólida y continua. Si se realiza correctamente, se crea un sello resistente, hermético y a prueba de fugas. El sellado térmico puede realizarse de diversas maneras: selladoras manuales por impulsos para bolsas, máquinas de barra caliente para recipientes o selladoras de banda continua en líneas automatizadas. Esta versatilidad significa que el sellado térmico se utiliza ampliamente para bolsas de plástico, bolsas para alimentos, laminados y bandejas de aluminio. Por ejemplo, los procesadores de alimentos utilizan selladoras térmicas para cerrar bolsas flexibles para bocadillos y sándwiches, garantizando así la frescura del producto durante el transporte. En resumen, siempre que sea necesario fusionar dos capas de embalaje termoplástico sin tapa, el sellado térmico es el método ideal.

Diferencias clave de un vistazo

La siguiente tabla resume cómo se comparan el sellado por inducción y el sellado térmico en factores clave:

| Característica | Sellado por inducción | Sellado térmico |

|---|---|---|

| Proceso | Calentamiento electromagnético sin contacto de un revestimiento de aluminio | Calentamiento por contacto de materiales de embalaje |

| Contenedor/Tapa | Requiere un recipiente tapado con un revestimiento de aluminio dentro de la tapa. | Puede sellar contenedores/bolsas abiertos (no necesita tapa) |

| Materiales Sellados | Revestimientos multicapa de lámina y polímero debajo de las tapas | Películas o laminados termoplásticos (plástico/lámina) |

| Aplicaciones | Botellas, frascos (farmacéuticos, salsas alimentarias, productos químicos) | Bolsas, bolsas, bandejas (envases de alimentos, bolsas de fluidos médicos, etc.) |

| Costo de la máquina | Moderado: requiere bobinas y controles (a menudo unidades móviles) | Bajo-moderado: barras calientes simples o mandíbulas de impulso |

| Costo de consumibles | Superior: los revestimientos de papel de aluminio son relativamente costosos | Abajo: utiliza películas de plástico/láminas económicas |

| Velocidad y rendimiento | Sellado de alta velocidad en el transportador; no necesita calentamiento | Muy rápido para sellado continuo de bolsas; la barra caliente necesita calentamiento |

| Versatilidad | Maneja diversas formas y tamaños de contenedores con cambios rápidos | Flexible en formas; puede sellar laminados de película personalizados |

| Seguridad | Sin llama abierta ni contacto con la mandíbula caliente; más seguro para los operadores | Contacto directo con el calor: riesgo de quemaduras y exposición al calor. |

| Evidencia de manipulación | Excelente (el papel de aluminio debe romperse para abrirlo) | Generalmente más bajo a menos que se utilice una película especial |

| Calidad del sello | Sellado hermético: excelente barrera contra la humedad y el oxígeno. | Sello hermético, pero las propiedades de la película afectan la calidad de la barrera |

Cada método destaca en diferentes escenarios. La máquina de sellado por inducción destaca en el sellado de tapas con sellos resistentes y de seguridad, mientras que el sellado térmico (incluidas las selladoras térmicas por impulso) es ideal para sellar bolsas y sobres flexibles.

Ventajas y desventajas

Sellado por inducción: ventajas y desventajas

● Ventajas: El sellado por inducción es sin contacto y, por lo tanto, muy seguro: ningún elemento calefactor toca el envase ni el producto. Las máquinas ocupan poco espacio y se encienden al instante (sin precalentamiento). Los sellos producidos son herméticos y a prueba de manipulaciones, lo que protege la frescura del producto y evita fugas. Los equipos de inducción modernos admiten una amplia gama de formas y tamaños de envases con un mínimo cambio de equipo. Los operarios simplemente colocan un tapón recubierto de aluminio en la botella llena y lo pasan por la bobina de inducción; el proceso es rápido y se integra fácilmente en líneas automatizadas.

● Contras: El sellado por inducción requiere una tapa compatible con un revestimiento de aluminio, por lo que no permite sellar bolsas ni cajas abiertas. Los revestimientos de aluminio aumentan el costo por envase y se requiere un equipo de inducción especializado. Existen selladoras de inducción sin tapa, pero son menos comunes y generalmente más caras. Además, dado que el sello está oculto bajo la tapa, no es posible la inspección visual inmediata de la capa de sellado (a diferencia de un sellado térmico visible). En la práctica, la inducción se utiliza principalmente para envases con tapa (botellas, frascos). Es menos adecuada para envases de gran tamaño o con formas irregulares que no pasan fácilmente por debajo del cabezal de inducción.

Sellado térmico: ventajas y desventajas

● Ventajas: Las selladoras térmicas son versátiles y rentables. Pueden sellar prácticamente cualquier tipo de película de plástico o laminado, así como laminados de papel aluminio. Esto las hace ideales para el sellado de bolsas de alimentos, bolsas de plástico y envases flexibles. El sellado térmico a menudo se puede realizar sin tapa ni tapón; por ejemplo, una bolsa o bolsa de plástico con producto en su interior simplemente se puede doblar y sellar térmicamente. El equipo suele ser más sencillo y económico inicialmente que la inducción; una selladora térmica por impulsos o una selladora de banda utilizan elementos calefactores básicos. El material consumible (película de plástico o laminado de papel aluminio) es económico, especialmente en comparación con los revestimientos de aluminio. En líneas automatizadas, las selladoras térmicas pueden alcanzar rendimientos muy altos (piense en líneas de bolsas para snacks o máquinas verticales de formado, llenado y sellado).

● Contras: El termosellado implica el contacto directo con una superficie caliente, por lo que existen consideraciones de seguridad. Los operadores deben evitar quemaduras, ya que el sobrecalentamiento puede dañar el envase o incluso provocar incendios. En la práctica, esto también implica que las selladoras térmicas necesitan tiempo de calentamiento y control de temperatura. Los sistemas automatizados de termosellado suelen requerir plantillas o torretas complejas para manipular envases abiertos, lo que complica la automatización. Cada tamaño o forma de envase puede requerir herramientas diferentes. Los sellos realizados mediante termosellado suelen ser resistentes, pero si se utiliza una temperatura o presión inadecuadas, pueden producirse pequeñas fugas (lo que afecta a la vida útil). Por último, el termosellado generalmente no requiere tapa: no proporciona inherentemente el mismo sello de aluminio a prueba de manipulaciones que la inducción, a menos que se utilice un laminado de aluminio en la bolsa.

Casos de uso e industrias ideales

Casos de uso del sellado por inducción: El sellado por inducción es frecuente en productos farmacéuticos y nutracéuticos, donde las agencias reguladoras (como la FDA) exigen cierres con precinto de seguridad. Los medicamentos de venta libre, las vitaminas y los suplementos suelen utilizar tapas con revestimiento de inducción para cumplir con estos requisitos y garantizar la frescura. industria de alimentos y bebidas También utiliza sellos de inducción para líquidos y salsas (por ejemplo, jugos embotellados, mermeladas, condimentos) para evitar fugas y oxidación. Productos cosméticosLos productos petroquímicos y los productos químicos especializados (aceites, solventes) pueden utilizar el sellado por inducción para proporcionar una barrera hermética fiable. En general, cualquier producto embotellado que requiera un revestimiento de aluminio bajo la tapa, desde enjuague bucal hasta aceite de motor, es apto para el sellado por inducción.

Casos de uso de sellado térmico: El sellado térmico domina la industria del embalaje flexible. Snacks, granos, comidas congeladas y muchos otros bienes de consumo se envasan en bolsas de film selladas por calor para conservar su frescura. Los productos médicos desechables, como las bolsas intravenosas y las bolsas de prueba, se sellan herméticamente por calor para mantener la esterilidad. Las selladoras térmicas también se utilizan para envasar textiles, artículos de ferretería y semillas agrícolas. Siempre que un producto se encuentre en una bolsa, sobre o bandeja de plástico/film, una selladora térmica (a menudo una selladora térmica por impulsos para bolsas o una selladora de banda continua para bolsas) es una solución probable. Las aplicaciones especiales de film, como los sellos adhesivos de aluminio en envases tipo concha, también dependen del sellado térmico. En resumen, el sellado de bolsas de alimentos, bolsas de plástico y envases flexibles con film son los principales dominios del sellado térmico.

Consideraciones de mantenimiento y seguridad

Sellado por inducción: Las máquinas de inducción tienen relativamente pocas piezas de desgaste, pero el mantenimiento regular es importante. El cabezal de inducción y la bobina deben mantenerse limpios y correctamente alineados. Como señala un experto, "la limpieza, inspección y mantenimiento adecuados del cabezal de sellado, el sistema transportador y otros componentes son necesarios para evitar la contaminación, el desgaste o el mal funcionamiento". Dado que el sellado por inducción implica energía de alta frecuencia, la seguridad eléctrica es fundamental: los operadores necesitan capacitación en el manejo del equipo y los procedimientos de apagado de emergencia. A diferencia de las selladoras térmicas, las unidades de inducción no tienen mordazas calientes ni llamas abiertas, por lo que son más seguras en términos de riesgo de quemaduras. Sin embargo, existen campos magnéticos, por lo que se deben respetar las directrices del fabricante (por ejemplo, precaución con los marcapasos o evitar objetos metálicos cerca de la bobina). Las comprobaciones rutinarias de la fuente de alimentación y la refrigeración (si la hay) garantizarán una calidad de sellado constante.

Sellado térmico: El mantenimiento de la selladora térmica se centra en el elemento calefactor y la cubierta de teflón (PTFE). El cable o elemento calefactor debe revisarse periódicamente; cualquier rotura o mal funcionamiento dañará los sellos. La tira o cinta de teflón que cubre el elemento es un consumible: se desgasta y debe reemplazarse cuando se degrada. Como señala Valdamark, «todos estos elementos, incluyendo la cubierta, la cinta y el propio cable calefactor, son piezas consumibles que se deterioran con el tiempo». El uso excesivo o el sobrecalentamiento acortan drásticamente su vida útil. Los operadores deben evitar usar temperaturas superiores a las necesarias, ya que una temperatura excesivamente alta no solo desperdicia energía, sino que también aumenta los riesgos y los costos. Por seguridad, las selladoras térmicas deben usarse en áreas bien ventiladas, ya que el plástico derretido puede emitir vapores. Las precauciones estándar (guantes resistentes al calor, protectores y dispositivos de apagado de emergencia) ayudan a prevenir quemaduras o incendios.

Recomendaciones: Elegir entre inducción y sellado térmico

Al decidir qué método de sellado usar, considere el tipo de envase y los objetivos del empaque. Si está sellando botellas o frascos que ya usan tapas de rosca o a presión, el sellado por inducción suele ser la mejor opción. Proporciona un sello hermético con precinto de seguridad justo debajo de la tapa. Las máquinas de sellado por inducción de SFXB, por ejemplo, se integran a la perfección con tapas con revestimiento de aluminio para tapar y sellar botellas en un solo paso. Por otro lado, si su producto se envía en bolsas flexibles, pouches o recipientes sin tapa, el sellado térmico es más apropiado. Una selladora térmica por impulsos es ideal para lotes pequeños de bolsas de plástico, mientras que las selladoras térmicas continuas automatizadas funcionan para líneas de pouches de alta velocidad. Para sellos de gran diámetro (más de ~70 mm) o bandejas rígidas, el sellado térmico directo puede ser más rentable. En general, considere el sellado por inducción cuando se requiere un sello de tapa de aluminio o precinto de seguridad, y el sellado térmico cuando necesita cierres sin tapón, de película a película.

Para muchos fabricantes, la elección puede no ser una u otra. Algunas líneas de productos pueden utilizar ambos métodos: por ejemplo, una planta de bebidas podría utilizar sellado por inducción en las tapas de las botellas y también selladoras térmicas para el envasado en bolsas de productos complementarios. En todos los casos, adapte la máquina al estilo de envasado y al volumen de producción. De sobremesa o selladores de inducción portátiles Pueden ser ideales para tiradas pequeñas o cambios de línea, mientras que las selladoras de tapas de tamaño completo de SFXB son ideales para líneas de gran volumen. De igual manera, una simple selladora térmica por impulsos de sobremesa puede ser suficiente para productos artesanales, mientras que los procesadores de alimentos de alto volumen invertirán en selladoras de banda en línea.

|

|

| Selladora de papel de aluminio por inducción electromagnética automática refrigerada por agua SF-2900D | Selladora de papel de aluminio por inducción electromagnética portátil SF-1010 |

Preguntas frecuentes (FAQ) sobre el sellado por inducción frente al sellado térmico

1.¿Qué es el sellado por inducción y cómo funciona?

R: El sellado por inducción utiliza un campo electromagnético para calentar un revestimiento de aluminio dentro de una tapa, uniendo una película de polímero al borde del envase. El proceso es sin contacto: una botella tapada pasa por una bobina de inducción, que calienta el revestimiento de aluminio mediante corrientes de Foucault. Esto funde una capa de cera y activa un sello de polímero que se fusiona al envase, creando un sello hermético a prueba de manipulaciones. Se utiliza ampliamente en botellas para envases de alimentos, productos farmacéuticos y productos químicos.

2.¿En qué se diferencia el sellado térmico del sellado por inducción?

R: El termosellado implica la aplicación directa de calor y presión a los materiales. Se presionan dos capas de película plástica (o película y lámina) entre una barra caliente, lo que provoca la fusión de los polímeros. A diferencia del sellado por inducción, que requiere un soporte de lámina y una tapa, el termosellado funciona sin tapas y permite unir superficies planas o bolsas. Es ideal para sellar bolsas de plástico y sellos de lámina en bandejas, mientras que la inducción se utiliza para sellar debajo de las tapas.

3.¿Qué industrias utilizan comúnmente el sellado por inducción o el sellado térmico?

R: El sellado por inducción es común en las industrias farmacéutica y nutracéutica, ya que los organismos reguladores suelen exigir tapas de seguridad. También se utiliza en envases de alimentos y bebidas (frascos de salsas, aderezos para ensaladas), cosméticos y productos químicos. El sellado térmico es omnipresente en el procesamiento de alimentos (bolsas para refrigerios, comidas congeladas), productos médicos desechables (bolsas intravenosas) y bienes de consumo donde se utilizan envases flexibles. En esencia, si un producto está en una bolsa o sobre, es probable que se selle por calor; si está en un envase con tapa, se utiliza el sellado por inducción.

4.¿Qué es un “revestimiento por inducción de calor”?

R: El término se refiere al revestimiento de sellado de aluminio utilizado en el sellado por inducción. Se trata de un disco multicapa dentro de la tapa: generalmente una capa superior de pulpa de papel, un adhesivo de cera, una capa intermedia de papel de aluminio y una película inferior de polímero. Bajo calor de inducción, el polímero de este revestimiento se funde y se adhiere al cuello de la botella, convirtiéndose en el sello. Estos revestimientos (también llamados revestimientos de inducción o revestimientos de inducción de aluminio) son los consumibles del sellado por inducción.

5.¿Es posible realizar el sellado por inducción sin tapa (inducción sin tapa)?

R: Sí, pero es un método especializado. El sellado por inducción sin tapón implica colocar una lámina precortada sobre la boca abierta del envase y luego activarla con un cabezal de inducción. Este método evita el uso de un tapón, pero es menos común y suele ser más lento. Para la mayoría de las aplicaciones estándar, se utiliza un tapón con un revestimiento de lámina.

6.¿Qué es un sellador térmico de impulso y cuándo se utiliza?

R: Una selladora térmica por impulsos es un tipo de máquina de sellado térmico donde un elemento calefactor se activa solo durante el sellado y luego se apaga. Suele ser un dispositivo de sobremesa con una barra accionada por resorte. Se utiliza para sellar bolsas de plástico, bolsas de aluminio y películas en volúmenes moderados. El operador coloca el extremo abierto de la bolsa entre las mordazas y activa el sellado. Las selladoras por impulsos se valoran por su eficiencia energética (sin calor constante) y su fácil uso en la sobremesa.

7.¿Cómo elijo entre el sellado por inducción y el sellado térmico para mi embalaje?

R: Adapte el método a las necesidades de su envase y producto. Utilice el sellado por inducción cuando tenga un producto embotellado con tapa y necesite una barrera de seguridad (p. ej., botellas de zumo o tarros de crema). Utilice el sellado térmico al envasar en film o bolsas (p. ej., bolsas para snacks o parches medicinales). Si la barrera contra la humedad y el oxígeno es crucial y se dispone de una tapa, la inducción es la mejor opción. Si la velocidad de producción es extremadamente alta con envases flexibles, puede ser preferible el sellado térmico. En casos ambiguos, compare el coste del equipo con el del material: los revestimientos de inducción cuestan más por unidad, mientras que el film termosellable es más económico.

| Referencias: | |

| 1. | FDA – Requisitos de embalaje a prueba de manipulaciones |

| 2. | Sellado por inducción, Sellador térmico–Obtenido de: Wikipedia |

| 3. | Los envasadores médicos y de alimentos se familiarizan con los selladores térmicos más inteligentesObtenido de:Resumen de embalaje |

Comentarios