In the fast-moving consumer goods (FMCG) industry, packaging efficiency and precision are critical to maintaining market competitiveness. The global demand for shampoo and detergent products reached $200 billion in 2024, with an annual growth rate of 5.2% (Statista). To meet this demand, manufacturers require high-speed, high-accuracy liquid filling solutions capable of handling diverse viscosities while ensuring hygiene and operational efficiency.

SFXB is a professional manufacturer of packaging machinery, with many years of industry experience, advanced technology, reliable quality, life-long after-sales service and other advantages, in the industry has a good reputation, especially in non-standard design experience, and has the ability to design the whole line, can directly provide “turnkey” service. Design, processing, assembly and debugging are using their own professional team, so that we can truly achieve quality and quantity, on-time delivery.

As a leading manufacturer of custom liquid filling machinery, we present our 5,000 bottles/hour (5L) Shampoo and Laundry Detergent Filling Line—an integrated, automated solution combining a shampoo filling machine, detergent filling machine, capping machine, and labeling machine into a seamless production system. This line is engineered to maximize throughput, minimize waste, and ensure consistent product quality for large-scale manufacturers.

|

| 5,000 bottles/hour (5L containers) laundry detergent & shampoo filling machine , capping and labeling production line solution |

Key Features of the detergent & shampoo filling machine, capping and labeling line

1.Detergent & Shampoo Filling Machine

20 Servo-Driven Nozzles: Dual-row filling ensures rapid, spill-free filling for 5L containers.

Material Compatibility: Contact parts use 304 stainless steel and PVC to resist corrosion from harsh chemicals.

Precision Control: PLC and touchscreen interface allow real-time adjustments for filling volume and speed.

|

|

|

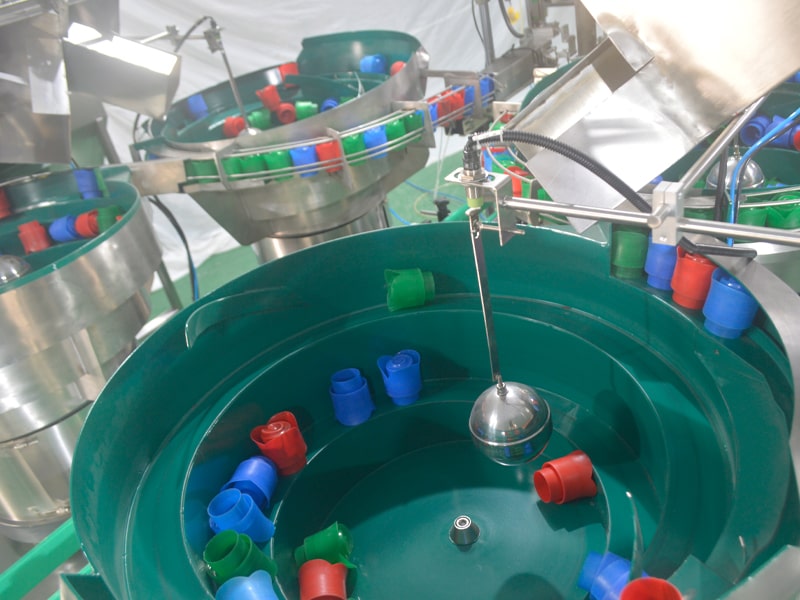

2.Capping Machine with Dual Stations

10 Rotary Heads: Split into two groups for simultaneous capping, achieving 5000 bottles/hour.

Vibratory Cap Sorting: Electromagnetic vibratory cap sorting system ensures smooth cap alignment and delivery.

Servo-Driven Torque Control: Prevents over-tightening and ensures consistent seal quality.

|

|

|

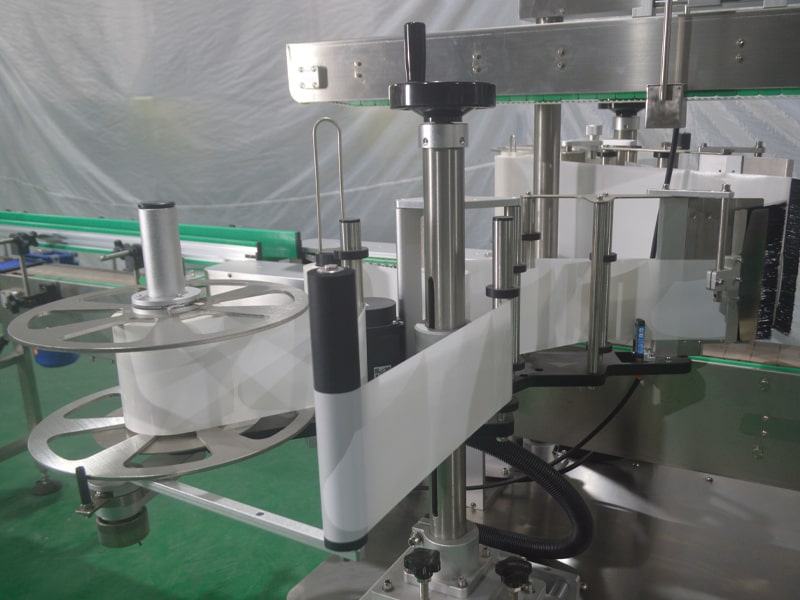

3.Dual-Side Labeling Machine

±1mm Accuracy: Ideal for non-transparent labels on curved or flat surfaces.

Flexible Label Rolls: Accommodates rolls up to 300mm in diameter.

PLC-Integrated Sensors: Detect bottle positions for flawless label placement.

|

|

|

4.End-to-End Automation

From manual bottle loading to automated cartoning, our line minimizes labor costs. The POM chain conveyor (speed: 0–15m/min) links all stations, while variable frequency speed motors ensure smooth transitions between processes.

Laundry detergent & Shampoo Filling Machine Line Solution Details

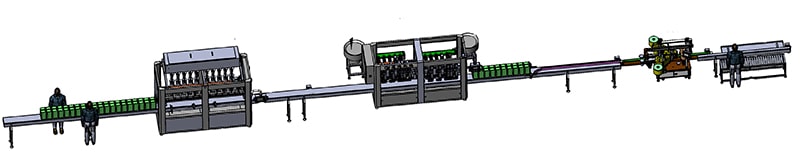

| Equipment distribution 3D diagram |

|

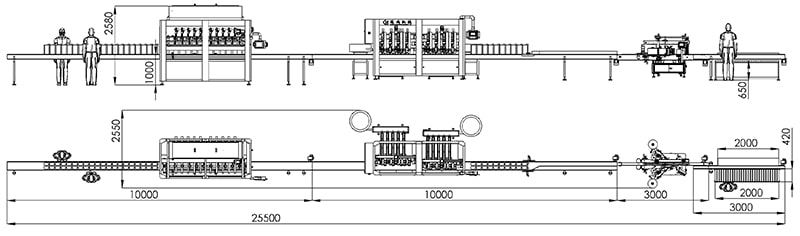

| Note: 1. The dimensions and appearance in the figure will be different in actual design. Please let us know if your company’s factory has restrictions; Customer freight elevator size&Customer factory door size; 2. The filling machine on this line must be manually divided into double rows for bottle loading and double row filling; 3. The capping machine on this line uses double-track capping, with 5 capping heads on each track; 4. Solution process:Manually divide the bottles into double rows to the conveyor belt → Automatic 20-head follow-up filling → Automatic vibration plate capping → Automatic 10-head follow-up capping → Automatic bottle collection → Automatic double-side labeling → Manual boxing |

| Equipment distribution 2D diagram |

|

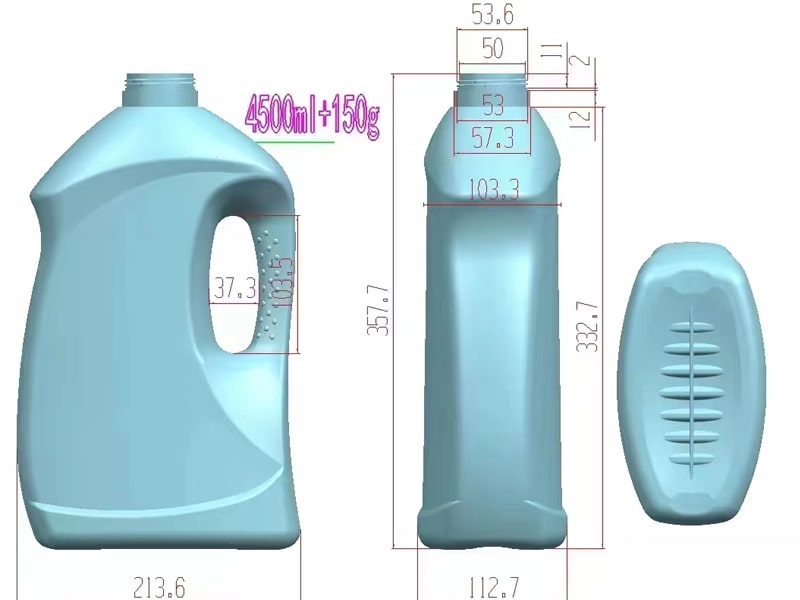

| Sample information |

| 1. Sample appearance: The customer provides a sample picture, as shown below, with a capacity of 5L. |

|

| 2. Filling materials: shampoo and laundry detergent. |

| Parameter | 20-head Following Filling Machine | 10-head Following Capping Machine | Double-side Labeling Machine | Packaging Conveyor |

| Head Quantity | 20 (dual-row) | 10 (5 heads/group × 2 groups) | — | — |

| Operation Type | Servo-following filling | Servo-following bottom capping | Double-side labeling (non-transparent adhesive labels) | — |

| Capacity/Specification | 5000ML | Customized (3L bottle sample provided) | Customized (bottle & label sample provided) | — |

| Speed | ≈5000 bottles/hour | ≈5000 bottles/hour | ≈5000 bottles/hour | — |

| Accuracy | ±1% | — | ±1mm | — |

| Frame Material | 304 stainless steel | 304 stainless steel | — | 304 stainless steel (frame & legs) |

| Liquid-contact Material | 304 stainless steel, PVC (tank & nozzles) | — | — | — |

| Control System | PLC & touchscreen | PLC & touchscreen | PLC touchscreen HMI | — |

| Power | ≈8KW (AC220V/380V 50/60Hz) | ≈11KW (AC220V/380V 50/60Hz) | ≈3KW (AC220V/380V 50/60Hz) | — |

| Air Pressure | 0.6-0.8MPa | 0.6-0.8MPa | — | — |

| Conveyor Specification | 254mm POM dual-hinge belt Speed 0-15m/min Height 850mm±25mm |

254mm POM dual-hinge belt Speed 0-15m/min Height 850mm±25mm |

114mm POM chain belt Speed 0-15m/min Height 850mm±25mm |

114mm POM chain belt Speed 0-15m/min Height 850mm±25mm |

| Conveyor Motor | Servo motor | — | 1.1KW VFD motor | — |

| Additional Features | — | Electromagnetic vibration disc cap sorting + belt separator | Label roll: Ø76mm core, ≤300mm outer diameter | Non-powered roller + collection table |

Key Configuration Notes

- Standardization: All machines use 304 stainless steel frames with unified conveyor height 850mm±25mm

- Control System: PLC and touchscreen interface implemented across filling, capping, and labeling machines

- Throughput Alignment: All equipment supports synchronized production speed of 5000 bottles/hour

Technical Specifications & Configurations

Our systems prioritize quality with globally sourced components:

PLC & HMI: Siemens PLC and 7-inch touchscreen for intuitive operation.

Sensors: German-made LEUZE infrared sensors for precise positioning.

Motors: Delta servo motors (Taiwan) and Panasonic inverter for energy efficiency.

Material Handling: AIRTAC pneumatic components and corrosion-resistant chain straps.

Applications Across Industries

This line is ideal for:

Cosmetics: High-viscosity shampoos, conditioners.

Household Cleaners: Laundry detergent, dish soap.

Industrial Liquids: Lubricants, chemicals.

Why Choose SFXB’s Packaging Solutions?

1.Unmatched Expertise in Liquid Packaging

With over 20 years in the packaging machinery industry, SFXB has honed its expertise in designing non-standard liquid filling systems for viscos products like shampoo and detergent. Our engineers leverage advanced PLC controls, servo-driven mechanisms, and corrosion-resistant 304 stainless steel to ensure durability and precision.

2.High-Speed, High-Accuracy Production

Our 20-head servo-driven filling machine achieves speeds of 5000 bottles/hour with a filling accuracy of ±1%, minimizing waste and maximizing throughput. Paired with a 10-head dual-track capping machine and dual-side labeling system, this line guarantees seamless integration for end-to-end automation.

3.Customizable and Scalable Designs

We understand that no two factories are alike. Whether your facility has space constraints or unique bottle specifications, our team adapts designs to fit your needs. For example, Our double-row bottle placement and adjustable conveyor heights (850mm ±25mm) ensure compatibility with diverse production environments.

4. Turnkey Implementation

From blueprint to operation:

• 3D factory layout simulation

• 72-hour continuous run test

• Multilingual operation manuals

FAQs: Your Questions, Answered

Q1: Can this line handle different bottle sizes?

A: Yes! Our liquid filling machine and capping machine are adjustable to accommodate various container heights and diameters. Share your bottle specs, and we’ll customize the guides and sensors.

Q2: What’s the lead time for installation?

A: Most lines ship within 2 weeks. Our team handles onsite assembly,debug, and training to ensure rapid deployment.

Q3: How do you ensure hygiene for shampoo filling?

A: All liquid-contact parts use FDA-grade 304 stainless steel and PVC. The open-frame design allows easy cleaning and CIP (clean-in-place) integration.

Q4: Do you offer after-sales support?

A: Absolutely. SFXB provides lifetime after-sales service, including spare parts, remote troubleshooting, and technician dispatches.

Q5: Can I upgrade to higher speeds later?

A: Yes. The modular design allows adding filling heads or upgrading motors for scalability.

Je recommande vivement SFXB(XueBa) pour la fourniture de solutions d’emballage innovantes et adaptées aux besoins spécifiques de chaque entreprise. Leur expertise en lignes de production complètes, notamment pour le remplissage, le bouchage et l’étiquetage, garantit efficacité et fiabilité. Leur équipe est toujours disponible pour conseiller et personnaliser les équipements, ce qui facilite la mise en place et l’optimisation des processus de production. Grâce à SFXB(XueBa), nous avons pu renforcer notre capacité de production tout en assurant la qualité de nos emballages. Leur professionnalisme et leur service après-vente sont remarquables, ce qui en fait un partenaire incontournable dans le domaine de l’emballage industriel.